Do you know what is the weight of slate 8 waves? But this information is very important for carrying out calculations, for example, of the truss system during the construction of buildings. As you guessed, our article will focus on such roofing material as slate, its types, technical characteristics and, in particular, its weight.

Do you know what is the weight of slate 8 waves? But this information is very important for carrying out calculations, for example, of the truss system during the construction of buildings. As you guessed, our article will focus on such roofing material as slate, its types, technical characteristics and, in particular, its weight.

Word "slate"came to us from the German language, where roofing slate tiles, mined by splitting special rocks, used to be so called.

When equipping modern roofs, slate is practically not used, while the “name” is firmly fixed for asbestos-cement roofing materials of a wavy shape, as well as for sheets of alternative materials of a similar shape, and therefore slate roof is now quite common.

Characteristics of asbestos-cement wave slate

Such slate is one of the most used materials for roofing, and has been for decades. And this is not surprising, since it is practical, inexpensive and very convenient to fit.

Wave slate - weight 1 sq.m. the roof of which is 10-14kg (depending on the thickness of the product), is made from a mixture consisting of asbestos, Portland cement and water.

At the same time, thin asbestos fibers, which are evenly distributed in Portland cement, perform the function of a reinforcing mesh, which significantly increases the impact strength and strength of the material.

The following types of wave slate modifications are produced:

- with a normal profile.

- With reinforced profile.

- With a unified profile.

Such sheets differ from each other in their size: the smallest of them are slate sheets with an ordinary profile, the largest with a reinforced profile.

As for the profile itself, here there are two types of sheets: 40/150, as well as 54/200, with the first number indicating the height of the wave, and the second - the step of the slate wave, indicated in mm.

According to GOST standards, the dimensions of wavy slate are determined as follows:

- their length is 1750 mm;

- width depending on the number of waves of the sheet can be:

- 980 mm for slate in 8 waves;

- 1125 mm for slate in 6 waves;

- 1130 mm for slate in 7 waves.

- thickness with profile 40/150 should be 5.8 mm, with profile 54/200 - 6 mm or 7.5 mm.

- the ordinary wave of the overlapping sheet, depending on the type of profile of the slate sheet, is produced with a height of 40 or 54 mm, while the overlapped one is 32 or 45 mm, respectively.

If you take a standard sheet slate 8 wave - its weight, depending on the thickness, will be from 23 to 26 kg.

Regarding the mechanical characteristics of this material, they are largely determined by such factors as:

- asbestos content;

- uniform placement in cement;

- fineness of grinding and others.

Advice! Remember that if you choose asbestos-cement slate as a roof for yourself, the weight of the sheet should serve as a guideline for choosing elements of the truss system of one thickness or another.

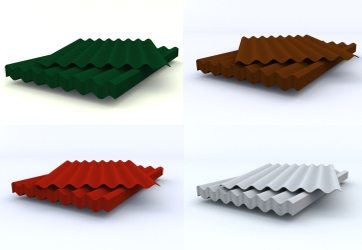

In order to improve durability, as well as decorative properties, slate is stained with phosphate or silicate paints using various kinds of pigments.

Often, wave asbestos-cement slate is painted in blue, red-brown, brick-red, yellow and other colors. Paint applied to slate protects the material from destruction, reduces its water-absorbing properties and increases frost resistance.

At the same time, the durability of slate sheets with a protective coating applied to them increases by 1.5-2 times.

Characteristics of flat asbestos-cement slate

Compared to wave slate, flat roofing sheet has somewhat similar properties, but still has some differences.

Such sheets are made in two ways: with and without pressing.

At the same time, the weight of flat slate produced with the use of pressing will be significantly higher than without it, however, the technical characteristics of the pressed sheet will be significantly higher.

For example, pressed slate is able to withstand at least 50 freezing cycles, while non-pressed sheet is almost 2 times less.

And even after the specified number of freezing cycles, the sheets remain strong enough, losing only about 10% in reliability from the initial indicator.

The rather high strength parameters of flat slate are impressive: depending on the manufacturer, the sheet is able to withstand a bending force of 20-50 MPa, and a compressive force of 90-130 MPa. .

However, the main advantage of a flat finishing material is the versatility of its use.

Flat slate - the weight that allows the construction of the roof base without additional reinforcing elements, is applicable not only as a roofing.

It can serve as both external and internal cladding of buildings, as partitions between rooms, it is in great demand in the agricultural sector and animal husbandry.

The versatility of the use of flat slate is connected not least with the high practicality and cheapness of the material.

Flat slate is resistant to aggressive environments, can be in contact with open soil for decades, is fireproof, and can be processed relatively well.

If we take into account the weight - flat slate is quite an acceptable material in this regard, both for roofing and for use in other areas.

Characteristics of wave bituminous slate

Wave bituminous euroslate or simply ondulin is a more modern product from a technical point of view than asbestos-cement slate sheet.

These types of coatings are completely different from each other, and from the common thing between them, perhaps, only the form, relatively low cost and purpose remained.

And how much does slate weigh with bitumen? With a sheet area of approximately 2 sq.m. its weight is only about 6.5 kg, which by the standards of roofing is simply a phenomenal result.

Most types of bituminous corrugated sheets are produced as follows:

- The fiber-bitumen mass, which includes bitumen, synthetic and vegetable fibers, dyes and plasticizers, is pressed at high temperatures. At the same time, the final density of the material is quite low, which to a greater extent determines the low weight of the slate sheet.

- Pressing is performed in several stages in a certain sequence, which results in a multilayer sheet structure, which gives the material high strength and resistance to mechanical stress. In this mixture, the bitumen serves as a waterproofing agent, while the organic matter stiffens the sheets.

- Impregnation with bitumen is also carried out in vacuum chambers in several stages, after which the sheets are painted.

Euroslate has a lot of advantages, including:

- Environmental friendliness of the material. It is not dangerous to the human body or the environment and is recyclable after the expiration of its useful life.

- Resistance to chemical influences, unsuitability for the development of bacteria and fungi, unpredisposed to organic decomposition.

- Ease of installation, which is determined immediately by a number of parameters. For example, the area of \u200b\u200bsheets in 2 sq.m.allows you to cover the entire surface of the roof in a short time, and the low weight of this type of slate sheet makes it possible to work with the material alone, without additional help.

- Flexibility and ease of processing even aluminum slate. The material is quite easy to cut with a hand saw or jigsaw.

- Durability, which varies from 10 to 30 years for different manufacturers.

Advice! With all the advantages of wave bitumen slate (ondulin), it is still not recommended to use it in areas with a hot summer climate, since bitumen softens slightly under significant thermal loads, due to which the sheet temporarily loses its declared rigidity and, accordingly, overall strength.

According to the method of painting, bitumen sheets are divided into 2 types - glossy and matte. Matte sheets are painted with acrylic paint, while they are rough to the touch.

Glossy sheets look prettier and brighter due to the addition of silicone to the paint, which provides this very gloss and shine. Glossy coated sheets are more expensive and less capable of retaining snow and dirt.

In addition to the above options for slate, corrugated roofing sheets made from plastic (PVC) have recently appeared on the market. They are used so far mainly for sheltering gazebos, terraces, all kinds of sheds and greenhouses.

Plastic slate is quite light, easy to process and install, and has many other advantages. Nevertheless, this is a novelty for the construction market, so so far few people dare to build more serious roof structures from it.

So, we found out what slate is, learned about some of its varieties, found out thanks to what and how much a slate sheet of one type or another weighs.

We hope that this information will later help you to more clearly and quickly decide on the choice of slate for sheltering the roof of your own house.

Did the article help you?