| Illustrations | Recommendations |

| Tool: - Hacksaw for wood;

- Strip bender;

- Level;

- Chopping cord;

- Hammer;

- Tongs for bending metal;

- stapler;

- Sealant gun;

- Scissors ordinary and metal;

- Knife;

- Square;

- Roulette;

- Screwdriver;

- Bulgarian.

|

| Calculation. Calculations are made based on the configuration of a particular model of ceramic tiles. The attached instruction contains all the necessary parameters. |

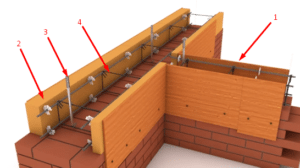

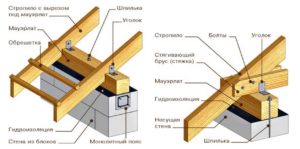

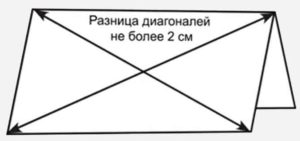

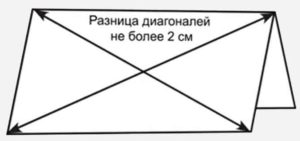

| For hard roofing materials it is important that the roof is of the correct dimensions, that is, not skewed, rectangular or square. Such planes are checked diagonally, how to check the roof diagonal is shown in the diagram. In practice, you just need to hammer the studs in the corners and measure the diagonals with a cord, the allowable error is 20 mm. |

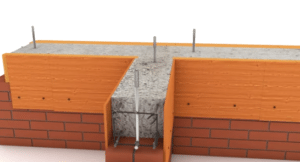

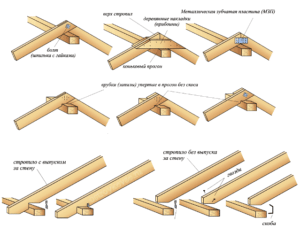

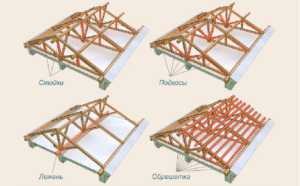

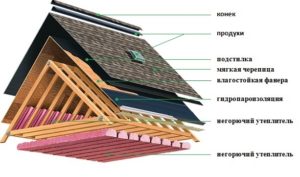

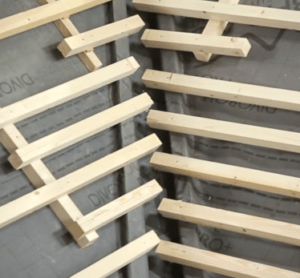

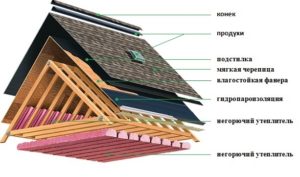

| What kind of crate is needed. There are 2 types of crates, solid and sparse: - For the arrangement of a continuous crate, OSB sheets or thick waterproof plywood are used, but such flooring is mounted only for soft roofing (bituminous tiles in the diagram on the left);

- For roofing works with rigid materials (ceramics, sheet metal, slate, etc.), a sparse crate is mounted.

|

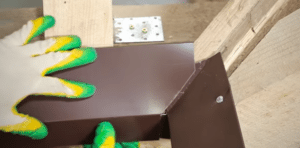

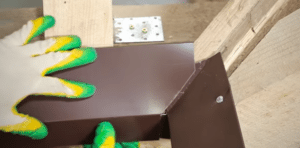

| Installing the cornice strip. The cornice strip or drip is fastened with self-tapping screws to the edge of the rafter legs around the entire perimeter of the roof. |

| Valley crate. On both sides of the valley, if any, crate bars are stuffed. From the bottom edge of the bar to the gutter line should be 150–200 mm. The bars are cut along the cornice overhang. |

| Vapor barrier installation. The valley boards of the crate are covered and wrapped with a vapor barrier membrane, the roll is rolled from top to bottom along the valley, the canvas is fixed with a stapler. |

| After arranging the vapor barrier along the valley, roll it out and fix it on the roof. We lay the strips from the bottom up, plus on the valley and along the side edge we make an overlap of about 30 cm. The canvas is attached to the eaves with double-sided tape. All adjacent planes, such as a ridge or a ridge of a hip roof, are also mounted with an overlap. The amount of overlap between adjacent strips of the vapor barrier membrane is marked on the membrane itself.

|

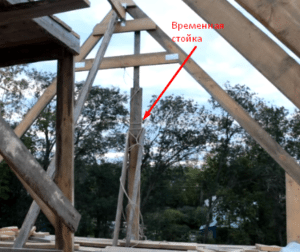

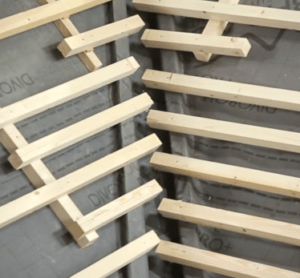

| Stuffing the counter-lattice. We use a 50x50 mm bar for the counter-lattice. The bars are stuffed along the rafter legs. A gap of 50 mm must be left between the bars of the counter-lattice and the valley bars. In the region of the ridge, the counter-lattice is cut at an angle and tightly joined. |

| On the bars of the counter-lattice polyethylene foam is attached, it is needed to seal the joint between the rafter leg and the bar. |

| We put the grid: - Now the lower board of the main crate is nailed over the dropper. In the corners and in the valleys, it is sawn and joined solid;

|

| - We attach a metal or plastic mesh to this board with self-tapping screws to protect the ventilation gap from birds.

|

| Trying on a gutter. Before nailing the first plank of the horizontal crate, you need to attach the tiles and see how much it will hang over the gutter of the gutter system, according to the instructions, this should be 1/3 of the diameter of the gutter. |

| Upper bar. The upper bar of the batten is fixed at a distance of 30 mm from the junction point of the bars of the counter batten. |

| Intermediate bars. Between the extreme bars, the location of the planks is calculated so that the tiles lie in whole rows, without undercuts. |

| Gable overhang. - Along the entire length of the gable overhang, a counter-lattice beam is attached from below;

|

| - Further, the vapor barrier is bent over the beam and fixed with a stapler;

|

| - A frontal board is nailed to the side of the pediment, after which the excess vapor barrier is cut off.

|

| Installation of a drainage system. - Brackets are attached to the edge of the cornice overhang with a step of 70 cm;

- The slope should be 3 mm per 1 running meter;

- First, put all the brackets together and mark;

- Next, we bend the brackets with a strip bender;

- We fix 2 extreme brackets;

- We stretch a cord between them;

- We fasten intermediate brackets along the cord;

|

| - We assemble the gutters, insert drain funnels into them and install end caps;

|

| - The drainpipe is assembled and mounted on the wall last.

|

| We install an apron. An apron is mounted along the edge of the roof overhang, and it is fastened with clamps along the upper edge. |

| Reinforced crate. A reinforced crate is stuffed in the valley area. |

| Gutter installation: - A corrugated drain gutter is mounted along the valley, the sections of the gutter are overlapped by 100 mm and fixed with self-tapping screws;

|

| - We attach a self-adhesive molding with water-repellent impregnation along the edge of the gutter.

|

| Aerostrip. Along the edge of the apron, the so-called airstrip is attached with self-tapping screws. The airstrip is mounted at a distance of 3-4 cm from the edge of the apron. It is necessary to ensure that the airstrip does not enter the valley, otherwise it will trap garbage there.

|

| Tiling. - First, a row of gable tiles is tried on and laid;

|

| - A gap of 10 mm is left from the frontal board to the inner edge of the gable tile, so the spike will need to be knocked down with a hammer from the inside;

|

| - Next, the tile segments are laid from right to left. Each segment is fixed in the upper part to the battens with 2 galvanized self-tapping screws.

|

| Installation of tiles in the valley. - Along the valley, the segments are cut and laid;

|

| - When cutting tiles for a valley, too small triangles should not be, in order to compensate for the distance, a half segment is inserted into the middle of the row.

|

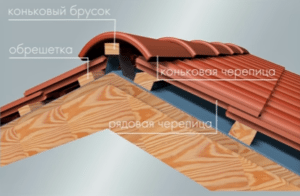

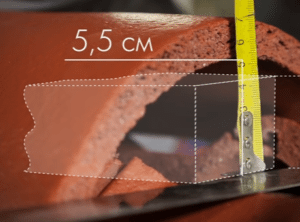

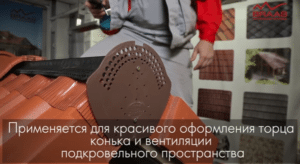

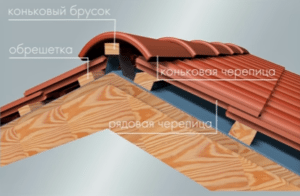

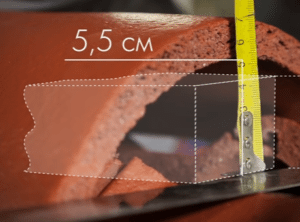

| Ridge arrangement. - Ridge tiles should lie on ordinary tiles, so the ridge beam is attached 1 cm below the arch of the ridge tiles;

|

| - To determine the location of the beam, we apply a ruler and measure with a tape measure;

|

| - Now we attach the supporting metal brackets to the crate and fix the ridge beam on them;

|

| - We roll out a special ventilated tape with a self-adhesive edge along the ridge, crimp it in the shape of the roof and fix it to the beam with a stapler;

|

| |

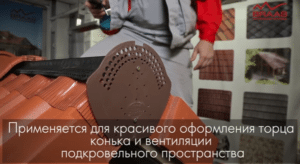

| - We fasten the end clamp from above and insert a segment of ridge tiles into it;

|

| - Further, all ridge segments are mounted in the same way.

The video in this article shows the entire installation process clearly. |