One of the most popular roofing materials, despite the emergence of high-tech competitors and a long history, remains slate. It is easy to use, cheap, and quite durable. When slate is used as a coating, the dimensions of the sheet allow installation to be carried out quickly and without any problems. What is the area of the slate sheet, and how to correctly calculate the amount of material for the roof - later in the article

One of the most popular roofing materials, despite the emergence of high-tech competitors and a long history, remains slate. It is easy to use, cheap, and quite durable. When slate is used as a coating, the dimensions of the sheet allow installation to be carried out quickly and without any problems. What is the area of the slate sheet, and how to correctly calculate the amount of material for the roof - later in the article

The name "slate" has taken root in domestic use, although, in fact, it is not entirely true. Translated from German, this word means "slate", a natural mineral material also used for the device. roof coverings.

Nevertheless, in our area, asbestos-cement (chrysotile-cement) sheets have long been called slate. The same name is sometimes applied to cement-fiber sheets, calling them asbestos-free slate.

Despite the fact that with the advent of promising materials such as euro-tiles, polymer slate or painted corrugated board, alternatives to asbestos cement have increased, the traditional product still occupies about 40% of the total volume of roofing materials used in construction.

Although it is often criticized for a number of shortcomings, sheet slate allows you to arrange a roof of the same area 2 or even 3 times cheaper than from the same galvanized sheet.

The main disadvantages of slate include:

- Relative fragility - the material does not tolerate serious shock loads (for example, large hail can simply riddle the roof) and large bending forces

- Relatively large weight - on average, a square meter of roofing has a mass of 14-16 kg, which requires a serious carrier system

- Hygroscopicity - asbestos fibers tend to absorb moisture and swell. With small roof slopes, this leads to the accumulation of water, the growth of moss, cracking under the influence of frost, and, ultimately, to premature wear of the material.

Important information! Roof slope must be at least 12%. The larger it is, the longer the coating will last..

- Relatively short service life. Manufacturers give a guarantee of 25-35 defrosting cycles for ordinary slate, which corresponds to the number of years of service. However, often well-arranged asbestos-cement roofs serve 100 years or more.

- Loss of performance over time. Each year of service reduces the strength of the sheet, microcracks appear on it, which worsens the degree of protection of the under-roof space from precipitation.

- The presence of asbestos in the material, recognized as harmful to health. In Europe, the use of classic slate is prohibited at all.However, taking into account the fact that between the operated premises and the roof there is a layer of waterproofing (and on a warm roof there is also a heater and a vapor barrier) and a ceiling, in our conditions, environmental considerations are often neglected

But the dimensions of the slate sheet allow you to immediately cover a fairly large area - for 10 square meters of the roof, on its flat sections, it takes 6-7 sheets.

This material has other advantages:

- Low construction cost slate roofs

- High manufacturability - for cutting slate, you can use any manual (hacksaw) or electric (grinder, circular saw) cutting tool

- Ease of installation - subject to the installation scheme, the roofer does not require high qualifications

- Using a sparse crate - the standard distance between its bars is 0.75 m

The slate normalizing according to the main indicators of GOST bears the number 30340-95 “Asbestos-cement wavy sheets”.

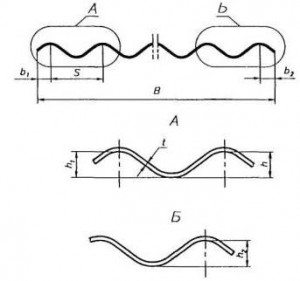

B - width

S is the distance between the tops of the waves

h - ordinary wave height

h1 – height of the overlapping wave

h2 is the height of the overlapping wave

Flat slate is regulated by GOST 18124-95 "Asbestos-cement flat sheets". There are also own developments of a number of manufacturers, which are produced in accordance with the technical specifications of the industry and their own development.

In accordance with GOST 30340-95, the dimensions of the slate sheet are reflected in its brand. In this case, the main indicators are the wave height and the distance between adjacent wave crests.

The document provides for two standard sizes according to these features: 40/150 and 54/200, where the numerator is the wave height, and the denominator is the distance between the centers of the peaks of adjacent waves.

The length, width and thickness of the sheet for each of the types are also regulated by the number of waves. An important parameter is the places of overlaps, for which standard values are also provided.

The industry produces the following types of asbestos-cement sheets:

- Flat slate - sheets with dimensions: width 1200 or 1500 mm, length - 2.5, 3 and 3.5 m, thickness - 6, 8, 10 mm

- Tiles, or scales - sawn flat slate, with dimensions of 40x60 mm

- 5-wave slate is an experimental development, the practical value of which is doubtful. With a wave pitch of 262.5 mm, the figures are as follows: with a size of almost 2 square meters (1.98), the useful area of \u200b\u200bslate (covered roof area) due to large overlaps is only 1.6 squares. That is, the unproductive consumption of material is more than 20%. The thickness of this product is 5.8mm

- 6-wave slate - usually used for industrial buildings, available only in size 54/200, with a width of 1125 mm. The thickest of all types of material - according to the standard, it can be 6 and 7.5 mm

- slate 7 wave - one of the most popular varieties, widely used for individual housing construction

- 8-wave - also very widely used. Favorably differs from the 7-wave larger width

Although products of a non-standard format are sometimes produced, in general, the dimensions of the slate sheet are unified: length 1750 mm - for all types, width: 1130 mm for 5 and eight-wave, 1125 mm - for 6-wave, and 980 mm - for 7- mi wave.

Some manufacturers, as a rule, of cement-fiber slate, offer custom-made batches with a sheet width of 0.92 and 1.097 m and a length of 0.625 to 3.5 m.

Such products are produced according to the European standard SE, and have a wave height of 5.1 cm, and the distance between the waves is 17.7 cm.

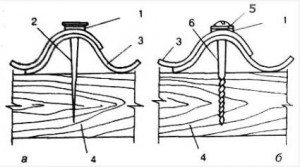

a- With the help of a roofing nail

b- Using a self-tapping screw

1-rubber gasket

2-nail

3-slate sheet

4-beam battens

5-metal gasket

6-self-tapping screw

Slate is also classified according to its purpose, and depending on the brand, it may have other sizes:

- UV (wavy slate of a unified profile, 175x112.5 cm - its most common size)

- VO (3) (wavy slate of an ordinary profile, 120x68 cm);

- VU (wavy slate reinforced profile, length up to 280 cm);

Important information! In this case, the useful area of \u200b\u200bthe sheet is calculated quite simply:

- 0.8 of the nominal - when overlapping sheets in a row for 1 wave

- 0.7 of the nominal - when overlapping in two waves

For example, with dimensions of 980 x 1750 mm (1.715 sq. M), the useful area of 7 wave slate will be 1.14 square meters. It should be remembered, when calculating the required material, that the overlap of sheets occurs not only in horizontal, but also in vertical rows of the roof.

In addition to the fact that GOST regulates the sheet size for slate, there are special requirements for shaped parts. Often, various nodes and junctions of the roof are made of galvanized iron.

But there are also parts made of asbestos-cement material.

GOST distinguishes the following types of parts:

- ridge overlay

- ridge overlapped

- simplified ridge overlay

- simplified ridge overlapped

- isosceles angular

- tray

At the same time, their length can be 1125, 1130, 1310 and 1750 mm, and the height of the intermittent wave - 46 and 60 mm, in accordance with what this size is 7 wave slate (it is similar for eight-wave), 5 and 6 wave.

Shaped parts are used to cover roof ridges, make valleys, and create drainage systems. These are very important elements for a slate roof, given that the material has absolutely no flexibility, and has a specific relief.

Separately, it is worth dwelling on one more option, in addition to the roof, for the use of asbestos-cement sheets. This is the device of fences, and even the walls of non-residential buildings.

As a rule, flat sheets are used for these purposes for reasons of economic feasibility, although sometimes there are also designs from corrugated ones. Slate straight has a larger selection of sizes, which expands the room for designers to maneuver.

In this case slate width, in combination with a large (up to 3.5 m) sheet length, allows you to cover large spans, while not putting excessive effort into the installation of supports. However, given the fragility of the material, it should be understood that one should not rely too much on the protective properties of such a fence - a collision with a car or a strong blow with a sledgehammer is guaranteed to form a hole in it. Although 10 mm thick slate is still able to withstand quite serious shock loads. It should also be noted that flat slabs are produced using two technologies - pressed and non-pressed. The former are more durable, although they are significantly more expensive.

The addition of pigments to the composition of the initial mixture, which has recently been practiced by many manufacturers, has a positive effect, including on the strength characteristics of the material.Unlike ordinary dyed slate, this type does not fade, and since the added pigment is of mineral origin, it slightly enhances the final product. Colored asbestos-cement sheets are produced in the same sizes as ordinary gray ones, they color both flat and wavy types of products.

ADVICE! Since when laying a slate roof, the vertical rows must be shifted relative to each other (so that continuous joints are not formed along the slope), a good solution is to use sheets sawn in half along the length through the row. This will make it possible to comply with technological requirements, and, at the same time, reduce material consumption, since sheet halves can be used in two rows at once. This method also eliminates the need to file the diagonal corners of the sheets, which is required with other laying patterns. When even rows start with halves, the shift is provided automatically and without any hassle.

Although asbestos-cement sheets cannot be called a particularly “flexible” material in terms of installation, nevertheless, the situation is simplified by what changes slate size without any problems, with the help of a tool available in any household. Thanks to this, and other advantages, the material will not disappear from the construction site in the foreseeable future.

Did the article help you?