Initially, slate was a small plate of chipped slate. But over time, many roofing materials have appeared that bear the same name. The only thing that unites them is that they are all sheet and usually have a profiled shape. In this article we will talk about them and try to find out which slate is better.

Types of slate

Natural slate slate

Shale plates can have different sizes and heights. The material has high decorative qualities, therefore it is considered elite. The main colors are gray and gray-blue.

Shale plates can have different sizes and heights. The material has high decorative qualities, therefore it is considered elite. The main colors are gray and gray-blue.

Occasionally found greenish and brown.

The roofing slate currently produced can be 25/60cm long, 0.4/0.9cm thick and 15/35cm wide.

Material advantages:

- natural slate is resistant to ultraviolet, so it does not lose its color during operation;

- has low thermal conductivity;

- provides good sound insulation;

- is not afraid and does not pass moisture;

- resistant to a wide range of temperatures - from very low to very high;

- has great durability and can last hundreds of years;

- not flammable.

Flaws:

- slate is quite heavy

- its installation is a rather complicated process;

- has fragility;

- the material is expensive and not every home owner can purchase it.

Asbestos cement sheets

The term "slate" today means artificial material, and first of all - asbestos-cement corrugated sheets of various sizes and profile depths, which have been used for more than a hundred years.

Such a Russian-made material for slate roof available in three types.

- VO - wavy ordinary slate, size 120 × 68 cm.

- VU - wavy reinforced, has a length of up to 280 cm.

- UV - unified wavy, the most common size is 175 × 112.5 cm.

Note! Asbestos-cement sheets produced now are often painted, so instead of an unpresentable white-gray color, they have a wide range of colors. Such slate is more aesthetic and durable, because the paint is also a protective layer.

The main advantages of this material:

- incombustibility;

- frost resistance;

- low thermal conductivity;

- ease of installation;

- long service life - up to 30 years;

- strength;

- cheapness.

Flaws:

- heavy weight, this requires the use of a powerful crate;

- fragility;

- unpresentable appearance of sheets having a natural color.

Euroslate or bituminous corrugated sheets

Relatively recently, a new type of roofing materials has appeared on the construction market - euroslate.

There are other terms that characterize it: asbestos-free slate, soft slate, bituminous slate, corrugated bitumen corrugated sheet.

This type includes: ondulin roofing, aqualine, nulin, ondura, gutta, etc.

Externally and in terms of production technology, the first four materials are almost the same.

The basis that these types of slate have is multilayer cellulose impregnated with polymers and saturated with bituminous vapors in a chamber at high temperature and pressure. The material is then dyed.

Slightly different in composition, appearance and properties of the gutta. These are bituminous corrugated sheets, which are reinforced with organic fibers. The top layer of the material is impregnated with resins and dyes.

Advantages of bituminous types of slate:

- strength;

- durability: 15 years warranty on materials, actual service life up to 50 years.

- ability to withstand significant snow and wind loads;

- lightness, the sheets weigh only 6/8 kg, which makes it possible to lay them on top of the old roof;

- the flexibility of the material allows it to be bent in length, this simplifies work on curved surfaces;

- aesthetic appearance.

Flaws:

- bitumen slate is quite expensive;

- does not have good resistance to high temperatures, softens in hot summer;

- becomes brittle in winter;

- does not have good UV resistance, so it can fade in patches.

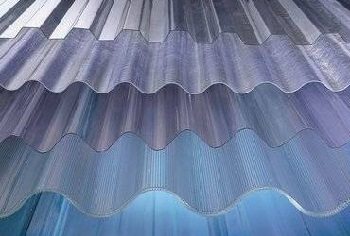

plastic slate

Transparent plastic slate is made from various types of polymers. The most common are PVC and polycarbonate. Now manufacturers of plastic roofing materials offer a wide range of colors and guarantee resistance to adverse weather conditions.

Translucent roofs are often used in the construction of swimming pools, greenhouses, winter gardens, pavilions, stops, garage sheds, attics. Therefore, when thinking about how to choose slate for such structures, stop on just such a coating.

Advantages of plastic slate:

- moisture resistance;

- resistance to chemically aggressive substances;

- ability to transmit sunlight;

- resistance to wind and snow loads;

- frost resistance;

- self-extinguishing ability, i.e. - low flammability;

- the low weight of such roofing material makes it possible to assemble the coating in the shortest possible time, while not resorting to additional work to strengthen the crate for it;

- plastic is very durable, for example, monolithic polycarbonate is very difficult to break, which also indicates the high safety of the coating.

Note! However, in addition to undoubted advantages, transparent and translucent slate also has a significant drawback: under the influence of high temperature, the sheets of this coating can expand. Be sure to consider this property of the material when arranging a plastic roof.

Rubber roofing sheets

Speaking about what kind of slate is, it is impossible not to mention such a variety of it as rubber. Its sheets are made from waste rubber and fiberglass.

The performance characteristics of such a roof are similar to asbestos-cement counterparts, but rubber slate is much lighter, which greatly simplifies the assembly of the coating from it.

In addition, rubber can be easily cut with a knife, it can be bent in curved and complex areas. Thanks to this, one person can lay the roof.

roofing material has the following dimensions: thickness - 0.4 cm, width - 69 cm, length - 81 cm, wave height - 2/3 cm.

It is used mainly for the construction of small buildings. Ideal for small outbuildings. It is good to cover extensions with a sloping roof, on which you need to walk to clear the snow.

Note! It should be noted that rubber slate is rather ambiguous as a roofing material, because it lacks two important positive performance characteristics of an asbestos-cement analogue. It is not frost-resistant and is flammable.

metal slate

Another type of slate can be called metal corrugated sheets, which are made from galvanized steel. Although it is more correct to call such roofing material profiled decking.

This slate has waves of different shapes and heights; it can be covered with a polymer protective coating from above. Previously, corrugated board was used only for arranging the roofs of large industrial buildings.

Now, when it has acquired an aesthetically attractive appearance, it is increasingly being used in domestic construction.

Did the article help you?