A roofing pie of a modern type should prevent the loss of heat in winter and its entry in summer, resist the penetration of water vapor from the room into the roof structure, “be able” to remove water vapor from the room that nevertheless penetrated into the insulation.

A roofing pie of a modern type should prevent the loss of heat in winter and its entry in summer, resist the penetration of water vapor from the room into the roof structure, “be able” to remove water vapor from the room that nevertheless penetrated into the insulation.

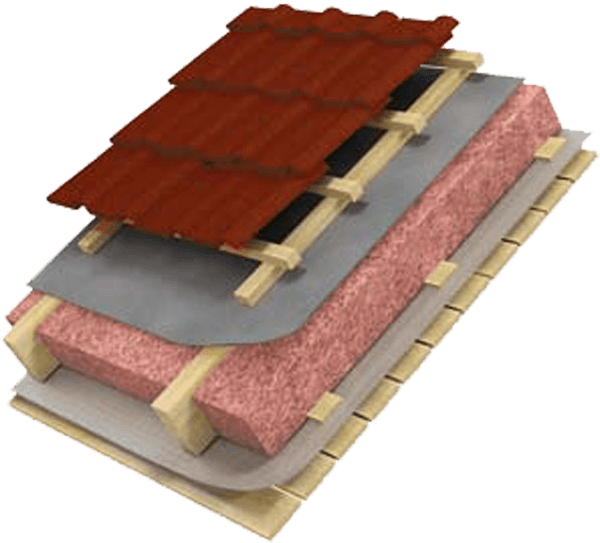

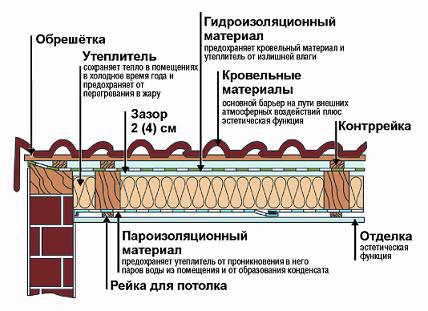

Such a well-designed multi-layer system should consist of the following elements in the following sequence, starting from the inside of the room:

- interior decoration;

- vapor barrier;

- thermal insulation;

- moisture insulation;

- one or more ventilation gaps;

- anti-icing system;

- roofing material.

Vapor barrier device

The purpose of the vapor barrier layer is, first of all, to prevent water vapor from entering the thickness of the thermal insulation from the room.

The device of the roofing pie begins with this layer, if you keep a report from the inside of the room, following the interior decoration.

The installation of a vapor barrier film consists in laying it with an overlap and fastening it with a connecting tape, which ensures the tightness of the vapor barrier layer.

In order to save money, glassine can become an alternative to special vapor barrier materials, which, however, loses its vapor barrier properties over time.

Modified materials have a layer of aluminum foil, which increases the fire resistance and thermal insulation qualities of the roofing cake as a whole. However, an air gap of about 2 cm thick is required between the film and the insulation layer, which slightly complicates installation and makes the structure more expensive.

The device of the thermal insulation layer

roof insulation must have increased vapor permeability, that is, freely pass through its thickness water vapor penetrating through the vapor barrier. Such properties are possessed by materials based on mineral wool. In addition, mineral wool boards must not deform over time and must be fire resistant.

Depending on the type of construction, either the ceiling of the upper floor or the enclosing structure of the attic - that is, the roof - can be insulated.

By itself, the insulation does not have a heating effect, but simply retains air in its fibers, which plays the role of a heat insulator.

If in roof insulation moisture penetrates (in a gaseous or liquid state), thermal insulation loses its properties, since it retains water, the thermal conductivity coefficient of which is 20 times higher compared to the thermal conductivity coefficient of air.

Advice! The right roofing cake is the one whose insulation always remains dry.

Water-repellent type impregnations for mineral and fiberglass boards, vapor and waterproofing, of course, contribute to water repellency, however, the mechanism of action of thermal insulation is adapted to water absorption.

Extruded polystyrene foam is able to resist diffusion and capillary water absorption, but this material costs significantly more than mineral wool and fiberglass.

It must be remembered that the laying technology roof insulation provides for installation after the moisture content of the wooden elements of the roof structure drops to 18%. Otherwise, moisture from the wood will penetrate into the insulation, and the waterproofing layer will prevent water from leaving the roofing pie.

Ventilation device for roofing pie and anti-icing systems

The advantage of a ventilated roof is that the insulation does not come into contact with the roofing material.

Roofing pie ventilation rules:

- If the roofing material is corrugated sheet, then ventilation holes and a ridge fan can be formed, even if the corrugated sheet is covered with a flat ridge.

- In addition to passive ventilation, equipment is also provided that can provide forced circulation of air flows from the eaves to the ridge.

- Near the ridge, cornice boxes and ventilation outlets are arranged. The set of soft type roofing materials includes a special ventilated ridge.

- Also, special holes are left in the lower part of the eaves. . They are protected from birds and insects. Mounted and ventilated skates.

- If for some reason this is not possible, the upper and lower ventilated gaps are connected to the atmosphere by means of special roof fans.

To combat the icing of roofs, the installation of a roofing pie may include anti-icing systems, which are a system of heating cables, temperature sensors and other equipment.

The system is mounted as follows:

- Lay heating cables in places where snow accumulates and ice forms, as well as around gutters and skylights.

- They provide power to the heating elements, signal transmission from temperature sensors to the control unit, which functions as a weather station, automatically turning off and on the system.

- The anti-icing system is laid at the design stage, and installed during the roofing process.

Installation of a waterproofing layer of a roofing pie

The waterproofing material is selected depending on the type of roofing material used. From the street during snowfalls, rains, fogs, moisture can penetrate into the attic space, and if the attic of the building is non-residential, and at the same time ventilation of the space under the roof is provided, the moisture will most likely simply disappear.

However, there is a possibility of damage to the wooden elements of the roof base. Plus, even with a careful vapor barrier, a small amount of water vapor will penetrate into the insulation.

For these reasons, a waterproofing layer is applicable, which, depending on the type of roofing material, either absorbs or passes steam.

When installing a waterproofing film, it is important not to confuse which of its sides should face the insulation and which should face the roofing material, otherwise the roofing pie will be ineffective.

Types of roof waterproofing:

- superdiffusion membranes. Water vapor can pass through them, while water itself cannot. Their vapor permeability is so high that they are installed without a lower ventilation gap, close to the insulation. This material is not applicable in combination with euroslate and metal tiles, since their reverse side is not designed for contact with moisture. The membranes are attached to the rafters with a counter beam, on which the crate is then mounted. Mounting the membrane close to the insulation usually makes sense when insulating an already residential building.

- Waterproofing diffusion membranes. They are films with micro-holes in the form of funnels, which face the inside of the room with a wide side. Their structure ensures the normal operation of the material only if there are two ventilation gaps - upper and lower. As a rule, they are used on roofs with bitumen-based roofing, as well as on tiled roofs. Such membranes are able to pass steam and retain moisture that comes from outside. The material should not come into contact with the insulation, as this will clog the micro-holes, from which they will stop conducting steam.Condensate is removed through the ventilation gap between the waterproofing and the roofing material (with a soft roof - between a continuous crate). Such membranes are applicable only in combination with roofing materials, whose reverse side is not afraid of contact with moisture.

- Waterproofing condensate films. They are vapor-tight and are designed to work with euroslate and metal tiles. At the same time, the presence of 2 ventilated gaps is mandatory. The side of the film, which is turned to the insulation, has a fleecy surface, where condensate is retained. Further, moisture is carried away along the lower air gap of the ventilation. The second side of the roofing, ventilated by the upper air channel, is completely protected from moisture.

The device of the truss structure as part of a roofing pie

The rafter system is mounted taking into account that the required thickness of the roofing cake of 30-35 cm can be made.

For the manufacture of rafters and other load-bearing elements, coniferous wood is used without defects. Its humidity should be no higher than 18-22%. Wooden elements must be treated with antiseptics and fire retardants.

A counter-lattice is mounted on the rafter system, on which the under-roofing layer of waterproofing is fixed. The gap formed in this case becomes part of the roof ventilation system.

Already a crate is attached to the counter-lattice, the device of which is determined by the type of roofing. The installation of the battens is carried out from a beam laid with a certain step or in the form of a continuous flooring from such modern composite wooden materials as OSB, DSP, etc.

At the final stage of construction, roofing is laid in a roofing pie.In this case, solid materials are laid on the crate, while soft roof materials are laid on a continuous flooring.

Did the article help you?