When developing house projects, an appropriate roof structure is necessarily selected. After all, it is the roof that gives the appearance of the house completeness and at the same time serves to protect the interior from the effects of the atmosphere. The supporting structure of the roof - the truss system - must be able to withstand the load that the roof exerts on it and external factors (snow, wind). Therefore, it is important to choose the right section and length of the rafters, and, if necessary, build up the rafters.

Let's see how this work can be done.

As a rule, in private construction, a board or timber is used for the manufacture of truss systems.These products have standard sizes that do not always correspond to the tasks. The required section of the rafters and their length must be specified in the project, the size of these parts is determined depending on the roof structure, the weight of the roof and the climatic conditions in the construction region.

But it happens that it is not always possible to find the necessary material. For example, a standard timber has a length of 4.5-6.5 meters, and the designed length of the rafter leg may be longer. In this case, you have to decide how to increase the length of the rafters.

It happens that you need to build up the thickness of the material, for this, additional elements are attached to the beam or board, which allow you to get the rafters of the required section.

Lengthening

During the construction of private houses, rafters are most often made of wood - logs, boards or timber.

In order to obtain a product of the required length, they resort to the following extension methods:

- Beam connection. It can be carried out end-to-end, overlap or by the method of oblique cutting.

- Connecting boards. In this case, composite or paired rafters.

Extension, by butt-joining

To perform an ideal connection of elements, the following conditions must be met:

- Butt ends rafters must be cut strictly at right angles.

Advice!

If this requirement is neglected and the ends are cut at an angle other than 90 degrees, then the joint will turn out to be unstable and, during the operation of the system, there will be a risk of deflection at the joint site.

- The joined rafters are folded end to end butt to each other, and they are connected using a metal plate with teeth

- The joint on both sides is reinforced with wooden overhead parts, which are nailed.

- When strengthening wooden linings, nails should be nailed in a checkerboard pattern.

Building, by overlapping

When making a connection in this way, there is no need to cut the ends at a certain angle. The overlap connection is made by laying the elements on top of each other so that the length of the overlap is at least a meter. Further, the parts are connected using nails, which are nailed in a checkerboard pattern.

Advice!

With this method of building, instead of nails, you can use studs with washers and nuts.

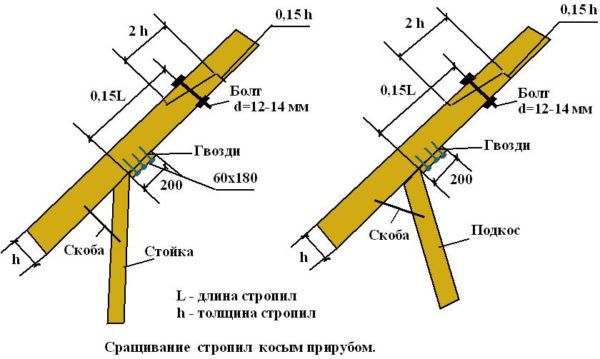

Increasing by the method of oblique cutting

When using this method, it is necessary to cut the ends of the parts strictly at an angle of 45 degrees. After that, the ends of the parts are folded together, and they are connected using a bolt having a diameter of 12-14 mm.

Advice!

When creating truss systems, the extended elements are installed so that the loads have a minimal effect on the joints!

Building roof rafters from boards

Let's consider how to increase the rafters in length, if they are assembled from boards.

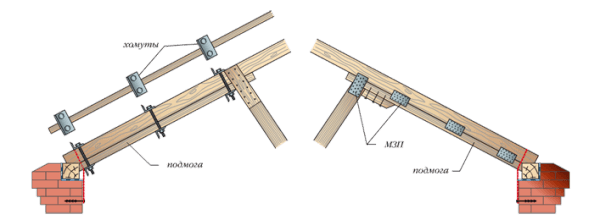

- The first option - composite rafters are being built. Two boards that need to be connected are placed "on edge".

The parts are connected through an "insert" - an additional wooden element that is installed between the boards.

The length of the liner must not be less than twice the height of the board, and the distance between the liner must not be greater than the height of the board times seven. This type of extended rafters cannot be used as diagonal ones! - The second option is to perform paired rafters. When using this method, two (or more) boards are stacked wide sides to each other (without a gap) and nailed, which should be staggered.

To increase the length of the product, an additional element is attached end-to-end to the first and overlapped to the second board. In this case, the distance between adjacent joints should be at least a meter, and they should be located along the rafters in a checkerboard pattern.

With the correct execution of the paired rafters, the joints will be located in a run-up, and each of them will be closed with a solid board.

Strengthening rafters or building in thickness

Often, homeowners are faced with the problem of how to strengthen the rafters already during the operation of the house. This happens if bars or boards of the wrong section were used to create truss systems. If measures are not taken in a timely manner, then the rafters may break, which will necessitate expensive roofing repairs.

Ways to strengthen the rafters

To strengthen the rafters, you can:

- Increase the thickness of the bars;

- Increase the width of the bars.

The second option is preferable, since with the same consumption of material it allows to obtain a structure that has a high resistance to loads. Therefore, consider this particular method of strengthening the rafters.

To complete the work you will need:

- Spanners;

- Face heads with a ratchet;

- Bulgarian;

- Drill and screwdriver;

- Hydraulic cylinder.

Advice!

Work to strengthen the rafters should be carried out with an assistant.

Job Recommendations

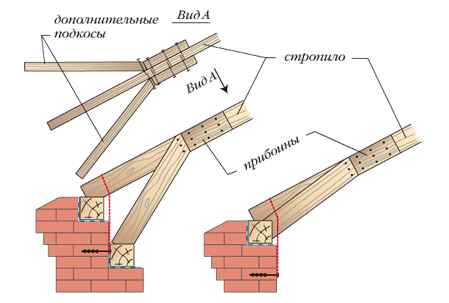

- At the first stage, you should pay attention to the fastening of the rafters to the ridge. If a discrepancy is noticeable in this place, then, using a jack, you should join the upper ends of the rafter legs, and strengthen them using a perforated metal tape or a board two centimeters thick.

- Next, the deflection of the rafters should be eliminated using a hydraulic cylinder. Before this, it is necessary to strengthen the joints of the rafter legs to the Mauerlat, for which a board is screwed on the side (when increasing the width of the rafters) or from the bottom (when increasing their thickness) using self-tapping screws. This board must also be screwed to the Mauerlat so that the rafter legs do not move apart during work.

- In a beam or board attached to self-tapping screws, we drill holes that must pass through both parts - the reinforced rafters and the hemmed beam. In this case, it is necessary to ensure that the holes are located not in a straight line, but in a “snake”.

- Fastening of parts is carried out using studs with washers and self-locking nuts.

Replacement of damaged rafter legs

If the rafters are broken or, due to moisture getting on them, part of the wooden structures is rotten, then you have to resort to radical methods. This method is the replacement of rafters.

Here are some tips for making this work:

- If you want to replace rotten rafters, then you first need to remove the roofing on both sides house roofs.

- Further, over the central part of the rafters, which are located next to the parts to be replaced, they cut the bars and carefully remove the nails.

- New rafters are installed in place of the damaged part, attaching them to the old bars. For fastening, nails 12-15 cm long should be used.

- If it is necessary to remove and replace the horizontal screed, then work begins with the installation of temporary racks supporting horizontal beams. Then the bearing racks are separated from the damaged part, which will be reused after replacing the part, and a new coupler is installed. After completion of work, temporary supports are removed.

- If it is necessary to replace the rack, a similar temporary rack is installed next to it with an emphasis on a board with a thickness of 2.5 cm or more. After replacing the damaged part with a new one, the temporary support is removed.

conclusions

The roof truss system is a load-bearing structure that experiences serious loads during operation. Therefore, the design and construction of these systems should be approached professionally and responsibly. If the technology is not followed, various problems may arise, the elimination of which will require laborious and complex repairs.

Did the article help you?