Slanted rafters, based on the wooden trim of the walls of the building (Mauerlat, rafter beam), or on the upper crown of a wooden frame, are used in buildings with small spans. What are the elements of their design and the order of the device - later in the article.

Slanted rafters, based on the wooden trim of the walls of the building (Mauerlat, rafter beam), or on the upper crown of a wooden frame, are used in buildings with small spans. What are the elements of their design and the order of the device - later in the article.

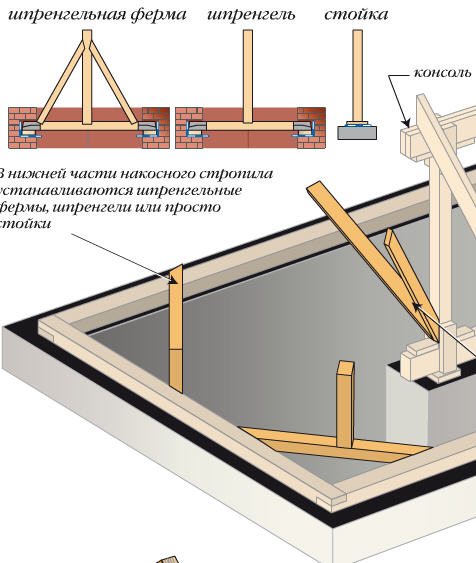

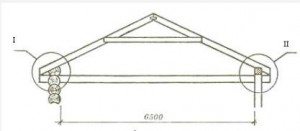

The maximum span that a layered truss system without internal supports allows to cover is 6-6.5 m. If there are load-bearing structures inside the building - walls or columns, racks can be installed on them.

By tightening the rafter legs with a crossbar, the span can be increased to 8 m, using one support - up to 12, and using two supports - up to 16 m.

Larger spans are rare in individual housing construction, so layered structures can be used in almost any private house.

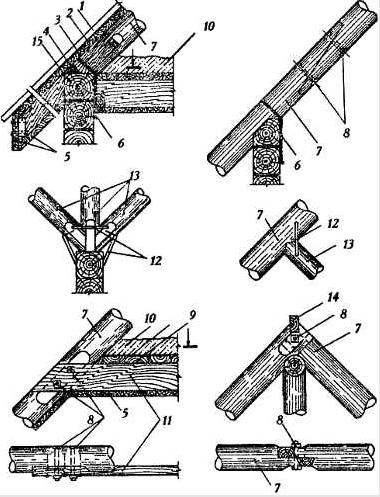

Since the rafters are supported here on the Mauerlat (in a wooden building, the upper row of the wall plays its role), the knot of this connection is very important.

It is impossible to lay rafters directly on a stone wall, as this will lead to condensation and rotting of the wooden parts of the structure. The Mauerlat itself also needs isolation.

Important information! Waterproofing devices require not only the rafter support unit on the Mauerlat, but also any adjoining wood to stone or metal structures. For this, a double layer of roofing material or other similar material is used.

1-rafter leg

2-mauerlat

3-twist

4-external load-bearing wall

5-cut

6-bed

7-internal load-bearing wall

8-waterproofing

How to properly fix the rafters on the rafter is a very important point when installing a layered roofing system. First of all, the Mauerlat itself must be securely fixed - for this, either metal pins are used, concreted into the wall to a depth of at least 40 cm, or bolts fixed in the same way.

It can also be wire twists Ф not less than 6 mm, laid during the construction of walls at a distance of no more than 3 rows of masonry from the upper edge.

Sometimes also used fixing rafters with staples to the Mauerlat. Mauerlat itself is a beam with a side of 140-160 mm. The same requirements apply to the bed - a beam that goes along the internal load-bearing structures.

In housing construction, wooden layered truss systems are used, since the use of metal or reinforced concrete elements is very difficult to implement here, if at all possible.

Therefore, for attaching the rafters to each other, as well as to all types of support bars and other parts, various carpentry joints are widely used - a spike, a tooth, a frying pan.

Since in a layered system, the structure bears the pressure of itself and the roofing cake, all these loads should be taken into account before the rafters are laid correctly.

Particular attention should be paid to the installation of roofing load-bearing structures on damp wooden log cabins, where shrinkage has not yet taken place.

Important information! The shrinkage coefficient of a log house made of logs or timber is 4-6%. With a wall height of about 3 m, in a year it can be reduced by 10-20 cm, which can adversely affect both the inserted woodwork and the load-bearing elements of the roof. These figures are laid down in the project initially (the dimensions of the house are given in two versions - initial and "post-shrink")

You can use hanging truss systems. Otherwise, the solution to the problem is possible in several ways: wait for the end of shrinkage, or install rafters with sliding supports, or put screw jacks (shrinkage compensators) under all supporting structures.

1-roofing material

2-waterproofing

3 crate

4 filly

5-boards

6-bar twist

7-rafter

8-bolts

9-floor boards

10-thermal insulation

11-beam ceiling

12-bracket

13-strut

14-ridge beam

15-mauerlat

The disadvantages of the first method are understandable - this is a long wait.The latter is also not optimal, as it will require high precision manual operations. Sliding mounts are virtually self-adjusting and have an added benefit.

Wood is a living material, and even after shrinkage it will “breathe” constantly. Of course, the deformations will not be so significant, but they will occur constantly - and the sliding structure perfectly compensates for them.

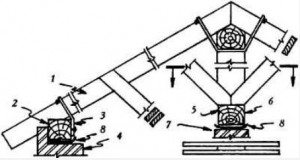

It looks like this: on the Mauerlat, with a bar stuffed at the right angle, or made by cutting the desired shape, a corner is attached, one of the shelves of which is bent. A working relief plate is threaded under the bend.

Since the direction of sliding will be directed outward, it is better to fix the plate on the rafter in such a way that as much as possible the distance for free movement remains towards the ridge of the building.

When purchasing a sliding joint, it should be remembered that their working size (the distance between the supporting pads of the plates) can be different.

It is selected depending on the planned degree of shrinkage and should not be less than it (you need to pay attention that the actual shrinkage size will be distributed to the rafters of both slopes).

Important information! It must be remembered that the support of the rafters on the rafter beam is not the only movable unit of this design. The ridge should also provide for an articulated joint of one type or another. Layered rafters can be joined end-to-end using metal plates, while leaving a sufficient angle at the ends so that when the rafters converge, they do not rest against each other. The second option is to connect the rafters to the overlay, using a through hole in both legs, through which one bolt passes.

Rafter constructions

Any truss system, where the upper attachment point is hinged, and the lower one has a hinge and a floating connection (slider, as in the variant above) refers to non-thrust.

In them, bursting loads are not transferred to the Mauerlat, and through it to the walls. Spacer rafters - a scheme where the ridge connection is rigid, and the support on the Mauerlat is with a hinge, for example, using a "tooth" connection, and it transfers the pushing force to the walls.

In fact, this is a hybrid scheme that combines layered rafters and hanging ones, especially when the horizontal scrum is low in the layered ones.

At the same time, due to the fact that the effort from the weight of the roof is taken directly by the rafter legs connected end-to-end and working in bending, the ridge beam practically does not work, and becomes an optional element of the system.

Important information! All bolted connections are made through pre-drilled holes 1 mm smaller than the diameter of the bolt or stud. If you make them too large, while the part chooses a free play, the Mauerlat may be damaged. This is especially true for the spacer scheme.

Depending on which connections are made rigid and which are hinged, different rafter options will work differently.

Under normal, unloaded operation, as a rule, all elements truss system experiencing approximately the same load.

However, in winter, with snowfall, a different weight tends to apply to each of the slopes.

If the racks are poorly fixed or incorrectly mounted, this can lead to a shift of the roof towards a more loaded slope.

This is especially true for a non-thrust circuit, where there is a possibility of displacement. The problem is solved by reliable fastening of the ridge beam from longitudinal shifts.

The order of work when installing rafters

- Using the following table, calculate their cross section along the length of the rafter legs.

- In the absence of lumber of the required length or thickness, they are obtained by nail splicing or self-tapping screws

- A rafter template is made if racks and struts are used in the design - also samples for them

Important information! It should be remembered that in hip roofs (which usually have 4 slopes), the length of the rafters located at the junction of the slopes will decrease from the ridge to the Mauerlat.

This is called a diagonal rafter leg (it is also called a slanting leg). Due to the rather complex design of such a roof, here the templates are prepared only for the elements of the main slopes, the rest is assembled and adjusted on the spot.

- After preparing and fitting all the materials, they are raised to the roof

- If the project provides for racks and a ridge beam (run) - they are mounted first, while, if necessary, the racks are additionally strengthened to the supporting structures of the building to avoid possible shifts

- Further, taking into account the above rules, the rafters themselves are installed to the fasteners, fixing them in one of the selected ways to the Mauerlat and in the place of the upper connection - to the ridge beam, or to each other

- After that, struts, sprengels and other supporting parts are installed.

- If the project includes horizontal contractions (which to a certain extent makes the schemes of layered rafters - hanging rafters similar), then at the next stage they are attached

- Depending on the length of the rafter legs and the structure of the roof, plumb lines are arranged. For most buildings, the roof should extend at least 50 cm beyond the outer walls to prevent precipitation from reaching the underside of the load-bearing structures. If the rafters are supported by a tooth or spike on the Mauerlat, a special extension element, a filly, is nailed to their lower edge from the side.

- If fillies are arranged, they are sheathed with a solid wooden crate around the entire perimeter of the building

At the next stage, the layered rafters are sheathed with a sheathing themselves - and the installation of a roofing pie from the selected materials follows: vapor and waterproofing, insulation and roofing.

Did the article help you?