The roof is one of the most important enclosing elements of the house, which must reliably protect the floors from external influences. The life of the house and its appearance depend on how well the roof is built. Consider how you can independently make rafters from boards and other material.

In the manufacture of truss systems, it is extremely important to avoid mistakes, and for this it is worth listening to the advice given by experienced builders.

The roof is one of the main elements of any structure. This design simultaneously performs several important functions.It is the roof that protects the interior of the house from the penetration of wind and precipitation, so it must be reliable and durable.

In addition, the appearance of the whole house largely depends on the type of roof, that is, this design also acts as a decorative element..

Roof types

There are a fairly large number of varieties of roofs.

Among those that occur most frequently:

- Shed. This is the easiest option, the construction of which can be handled by an inexperienced builder. However, such a roof looks too simple, so this variety is usually used in the construction of various outbuildings - garages, bathhouses, outbuildings, etc.

- gable. This option is often used in the construction of private houses and cottages. One of the options for a gable roof is a broken or mansard. Both of these structures are quite complex, but having a competent project plan, you can cope with the construction of such roofs on your own.

- hip. This design, as well as its variety - a hipped roof, are quite complex, therefore, as a rule, their construction is trusted by professionals. But on the other hand, this version of the roof is one of the most reliable, capable of withstanding strong wind loads.

- Cross, hipped, domed roofs have a complex structure, so they are less often used in private construction.

Any roof structure consists of two main elements: the roof and truss system, which, in turn, includes rafters and floor beams. The rafter system is the bearing part of the structure, and the roof is the enclosing one.

Materials for the manufacture of rafters

As already mentioned, roof truss systems are load-bearing, that is, they must be able to withstand the design loads. Therefore, the material for the rafters must have high strength characteristics and be durable.

In private construction, wood is most often used for the manufacture of rafters. At the same time, special requirements are imposed on the material. So, the rafters must be made of coniferous wood of the first grade, not have a large number of knots, cracks and be well dried.

It can be used for the construction of truss systems logs of appropriate thickness. However, this material is heavy, so roofers do not recommend using it. It is much more convenient to use boards or a rafter beam. These materials are easy to install because they are quite light. And this is especially important if you plan to do the work yourself, without resorting to the help of professional roofers.

Less often in private construction, truss systems made of metal are used. In this case, the structures are more reliable and durable than when using wood. Metal rafters are chosen if it is necessary to increase the rigidity of the roof, as well as in cases where the roof has long spans.

Advice!

If the length of the roof span exceeds 10 meters, then it is recommended to use not only metal rafters, but also replace the Mauerlat beam with a metal channel.

The fastening of the rafter legs in this case can be carried out by welding and metal corners.

However, metal roof trusses are not used so often in private construction, since their installation is rather complicated.

- rafters made of metal are distinguished by their impressive weight, that is, to raise the trusses to the required height and install them, it is required to use construction equipment.

- A rafter system made of metal is more expensive than a similar structure, for the manufacture of which a rafter board was used.

Types of rafters and their sizes

The main types of rafters used in the construction of roofs are hanging and inclined rafters.

hanging rafters

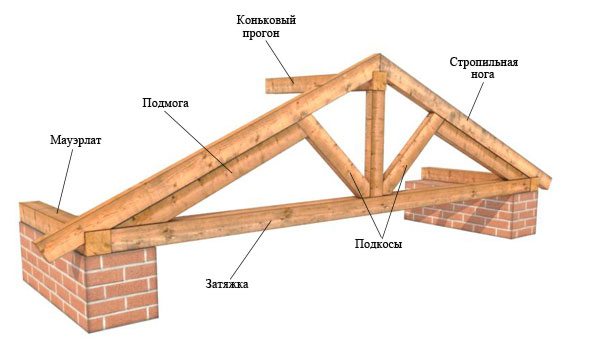

Hanging rafters are usually called a structure consisting of two rafter legs and a tightening beam that connects them at the bottom. To give the structure the necessary rigidity, additional elements are introduced into it - crossbars, or additional supports are performed for each pair of rafter legs.

Another option that allows you to give the structure rigidity is to install struts located at an angle of 45 degrees to the rack and abutting the second end against the rafter legs.

sloped rafters

This design consists of two rafter legs, which abut with their ends against the Mauerlat. The opposite ends of the rafter legs are laid on a beam-girder, which is mounted on racks supported by the inner wall of the house.In some cases, inclined rafters are installed without an internal run (this is possible with a house width of less than 7 meters). In this case, each pair of rafter legs is connected to each other using a crossbar.

The size and section of the rafters

To correctly determine the size of the rafters, the following factors must be taken into account:

- Estimated load. Here you should take into account the weight of the future roof, the amount of snow in the winter, the strength of the wind.

- The dimensions of the spans in the house.

- The slope of the roof, that is, the angle of installation of the rafters.

- The pitch of the rafters.

Advice!

As a rule, for the climatic conditions of the middle lane, it is recommended to build gable roofs with a slope of at least 30 degrees with a rafter spacing of at least 120 cm.

What is the relationship between the installation step of the rafter leg and its cross section?

- If it is planned to install rafters in increments of up to 300 cm, then it is allowed to use boards for rafters having a section of 8 × 14 or 6 × 14 cm. You can also take a bar measuring 10 × 12 cm.

- If the step is 400 cm, then a material with a section of 8 × 18 or 6 × 20 cm is required. When using a beam, its size should be 10 × 16 cm.

- With a step of 500 mm, boards 8 × 22 or bars 10 × 20 cm are needed.

Advice!

If it is necessary to use a material with a smaller cross section, it is necessary to use additional elements in the design - struts.

Methods for connecting rafters

The choice of method for attaching rafters depends on what material the house is built from, as well as on the design of the roof.

Mounting can be done:

- With the help of a Mauerlat.

- By installing rafter bars and tightening.

- Through the beams that make up the floor.

- If the rafters are attached to the log house, then the rafter legs can be attached to the upper crown of the log wall.

- During the construction of frame houses, fastening to the upper trim of the structure is used.

Work recommendations:

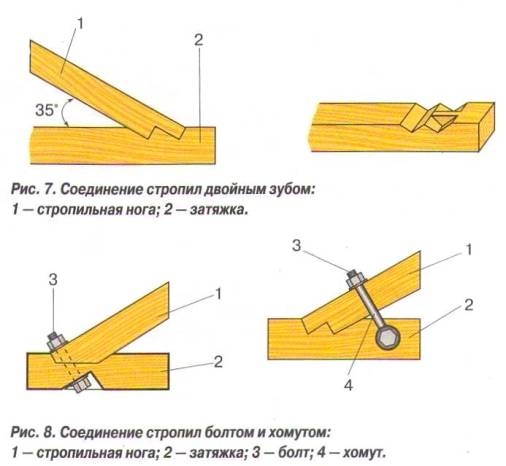

- In order for the end of the rafter leg not to slip off the beam and not chip it, a “tooth” connection is used, while the cut should be made at a distance of 25-30 cm from the edge.

Advice!

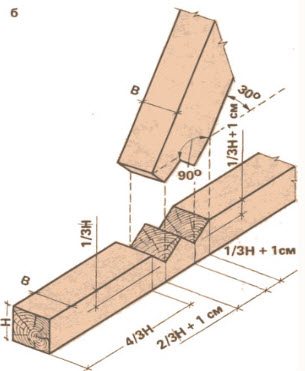

To properly implement the groove-tooth connection, proceed as follows.

They retreat from the puff edge by an amount equal to a quarter of the puff height and draw a line parallel to the edge here.

The resulting angle should be divided into two equal parts, and draw a line from the top of the corner to the intersection with the first marked line.

The point of intersection of the lines is connected to the underside of the rafter leg, as a result of which the outline of the tooth is obtained. Now you need to cut a “nest” in the beam, and a “tooth” in the rafter leg.

- To increase the area of \u200b\u200bsupport for the rafter leg on the beam, a “double tooth” connection is used. At the same time, for the first tooth in the beam, an emphasis and a spike are made, and for the second, only an emphasis.

Advice!

As a rule, the height of the first "tooth" is a fifth of the puff thickness, and the second - a third of this value. But some craftsmen prefer to make the "teeth" the same size.

- To give the connection strength, use bolts or staples for rafters. Since the use of bolts can somewhat weaken the cross section of the rafter leg, the second option is preferable.

- When connecting the strut to the headstock, a nest is made in the latter, a “tooth” is cut out in the strut.

- If the span is more than 4.5 meters, then the rafters are attached to the ridge by installing a ridge beam. The beam can be fixed to the top of the rafters, for this, the corresponding corners are cut out in it. A variant with a lower fastening of the beam is possible, for which small cutouts are made in the rafter legs themselves.

- When building a roof with a light roof and small spans, the ridge beam can be omitted. In this case, the ends of the rafter legs are overlapped together. Can be used to attach a rafter plate.

- To give greater rigidity to the structure, which does not include a ridge beam, it is recommended to additionally fix a crossbar between the rafters, under which to make a rack.

- In order to protect the walls and foundation of the building from moisture, the roof is equipped with an overhang. So, for wooden houses and log cabins, the overhang should be no less than 55 cm. This circumstance must be taken into account when the rafters are assembled.

- In the event that the overhang is large, and the beam is laid along the inner edge of the walls, a deflection in the roof may occur. To avoid such a risk, the mauerlat is laid with some indentation from the inner edge of the walls, and the deflection in the structure is leveled by reinforcing the board on the “edge”.

conclusions

The construction of the truss system is an extremely responsible event that requires special knowledge and skills. If the construction of a roof of complex shape is planned, then the drafting and execution of work should be entrusted to professionals.

Did the article help you?