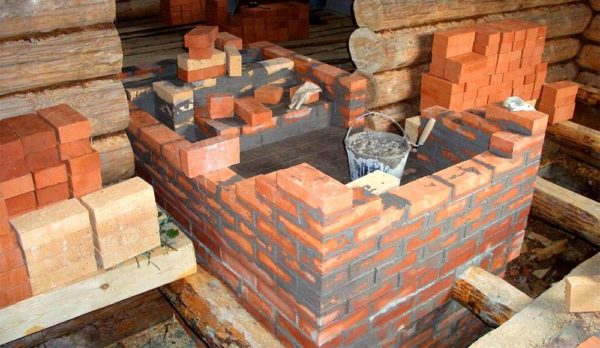

A mixture for laying bricks for the oven can be purchased ready-made, or you can make it yourself. With proper preparation, a home-made solution can surpass the factory one in terms of plasticity and heat resistance, but most importantly, it will cost you much less. I will share my experience in preparing a mortar for laying stoves and fireplaces according to various recipes.

Recipe 1. Clay binder

Selection of components

Solutions for furnaces should be plastic, durable, hold building blocks well. But the main thing is that the material should not crack when exposed to high temperatures. These requirements are met by the following compositions:

- clay;

- calcareous;

- cement.

The most popular mortar for laying a brick oven is clay. With strong heating, ceramization of clay minerals occurs, and the material acquires the necessary strength.

Main components:

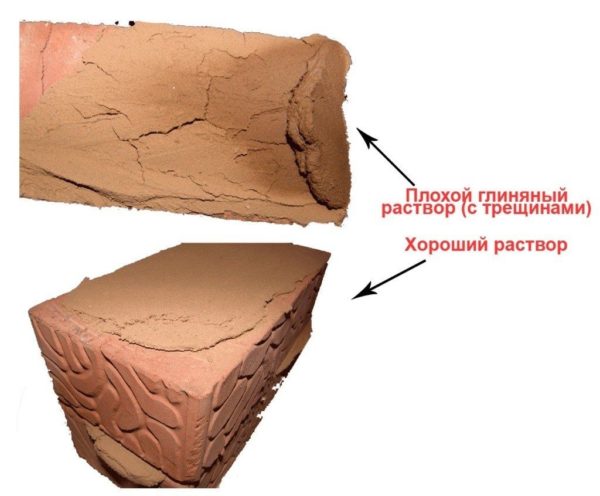

- Clay. We take pure clay, preferably medium fat. Skinny clays are not endowed with the necessary plasticity, and too fat ones crack when heated.

If it is planned to use a refractory (refractory) brick, then we replace part of the clay / sand with fireclay.

- Sand. Optimal - fine-grained quarry. The smaller the sand grain, the thinner the masonry joint can be made.

- Water - clean, cool (but not cold). To harden the solution of clay in water, it is desirable to add table salt.

Cooking methods

Clay mortar is quite simple to prepare. And yet there are several ways to knead clay, which allow you to get compositions with different properties.

| Mortar type | Cooking process |

| Standard |

|

| Refractory |

|

| asbestos |

|

It is quite simple to check whether we have chosen the composition of the mortar for laying a brick oven:

- From the finished mixture we roll several balls with a diameter of 5 mm.

- We dry the balls in a ventilated room (no draft!) for 8–12 days.

- The dried ball is thrown onto the floor from a height of 1 m.

If the ball did not break, and cracks appeared only on the surface, the composition is suitable!

Recipe 2. Lime binder

Both the base of the furnace and the brick chimney do not experience such temperature loads as the structure body itself. So instead of clay, lime dough is used as a binder for the solution. Masonry mixtures based on it tolerate heat worse (maximum - 500 ° C), but if the technology is followed, they surpass clay in strength.

Preparing lime mortar for the kiln:

- Preparation of lime dough. To do this, quicklime is placed in a special box, which is then filled with water. During the cooking process, the composition is gradually extinguished, and due to dehydration it turns into a lime paste.

This process is quite complicated and traumatic, therefore it is easier to buy ready-made dough. Moreover, its price is quite low (up to 30 rubles per kg).

- Preparation of components. To improve the quality of the solution, moisten the dough and wipe through a sieve. We sift the sand to remove organic impurities and large mineral granules.

- kneading. We dilute the mashed dough with water, after which we add sand. The amount of sand depends on the requirements for the masonry mixture, but the most commonly used compositions with a dough ratio: sand is approximately 1:2.5 or 1:3.

The finished mortar should be plastic and not tear when spread with a trowel on a brick.

Recipe 3. Cement binder

Where there is no exposure to high temperatures, a cement-based masonry composition can be used. In terms of heat resistance, it is inferior to clay, but it is easier to prepare and under normal conditions it cracks much less often.

Cooking scheme:

- Preparation of components. We carefully sift the sand, and check the cement for lumps. After that, we prepare a mixture of sand and cement in a ratio of 1: 3.

Usually, cement grade M400 and higher is taken for masonry - it needs relatively little, so the strength of the material comes to the fore.

- kneading. Add water to the dry mixture in small portions. The solution is thoroughly mixed, breaking up lumps and trying to ensure that all the cement reacts with water.

- Usage. The cement mortar polymerizes quite quickly, therefore it is advisable to use it in the first hour after preparation. For large volumes, it is worth kneading the right amount of dry mixture, which, if necessary, is diluted with water.

Under no circumstances should water be added to partially set cement. In this case, the strength of the material will decrease by an order of magnitude, and when it dries, it will behave unpredictably.

In addition to being used in its pure form, cement can also be added to other mixtures for kiln masonry. Clay-cement and clay-lime mortars are used both for the construction of chimneys and for the construction of the furnaces themselves.They are strong enough, and the lack of heat resistance of cement is compensated by the presence of other components.

Conclusion

You can prepare a solution for laying furnaces with your own hands according to different schemes. The main thing here is to choose a sufficiently pure raw material, strictly observe the proportions and manufacturing technology. The video in this article will help you understand the methodology of work, and you can ask any questions you have in the comments to the material.

Did the article help you?