For a building structure, the foundation serves as the basis, and for the roof - the truss system. You can build layered rafters with your own hands for a small house, garage, bathhouse or outbuilding. Of course, you can do this process alone, but it is more convenient to do this with an assistant. The features of the independent device of the truss system are discussed in this article.

For a building structure, the foundation serves as the basis, and for the roof - the truss system. You can build layered rafters with your own hands for a small house, garage, bathhouse or outbuilding. Of course, you can do this process alone, but it is more convenient to do this with an assistant. The features of the independent device of the truss system are discussed in this article.

Material for rafters

So how to put together a roof with your own hands?

The most common material for the truss system is softwood, due to the fact that it is easy to process, it has a relative price.

The most suitable option for rafters is a wooden beam 10-15 cm wide and 5 cm thick.

The advantage of wood over metal is that the structure is light and strong enough that you can build it yourself.

When mounting the rafters with your own hands, it must be remembered that the size of the beam depends on the roofing used, the length of the rafters and the angle of their installation.

Attention. It is important for the truss system to take aged wooden material. This eliminates the possibility of changes in the geometry of the beam and, as a result, changes in the structural shape of the roof.

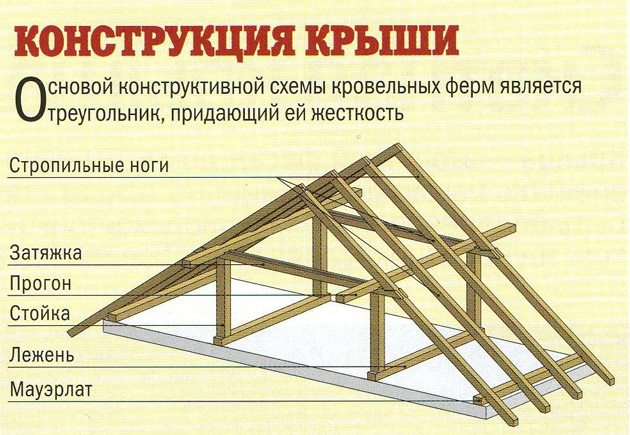

Elements of roof structures

roof rafters refer to the supporting structure of the roof, they can be supported by building supports or walls.

The design of the rafters is divided into two groups:

- hanging;

- layered.

The elements of layered rafters include:

- rafter legs (beams placed along the slopes);

- runs;

- racks;

- struts;

- lie down.

Rafter legs protect the roof from deflection. The remaining elements support them and transfer the load to the supporting pillars and walls.

The system of layered structures is used if there are vertical pillars in the structure, the span distance between which does not exceed 8 m.

Spans of this size are easily covered by layered rafter legs, which are located at a distance of 800 - 1200 cm from each other.

The step size of the rafter legs is set by constructive calculation.To strengthen the structure, when complex truss systems are used, a system of racks is used, the elements of which rest on the beds and support the run (longitudinal upper beam).

The upper ends of the rafter legs rest against the girders, and the lower ends against the Mauerlat (rafter beam). In turn, the Mauerlat is mounted on the upper edge of the wall. Its purpose is to distribute the load from the rafters to the wall.

For the stability of the rafter legs, struts are constructed between the run and the rack, forming a sub-rafter frame with the runs.

Attention. The angle between the rack and the struts should not exceed 45 degrees.

Rafter system

The type of truss system depends on the design of the roof. The most commonly performed structures are a gable roof, in which the rafter legs are the sides of a triangle.

Let's take a closer look at this design.

When the rafters are installed with their own hands, the rafter beams rest against the walls, which serve as a rigid support. In this design, there is no removal of beams beyond the surface of the building.

In order to prevent precipitation from falling on the wall of the structure, shackles (additional cantilever part) are built up to the rafters. Rafter legs are evenly spaced along the entire length of the roof at a distance of 0.6 to 1.2 m.

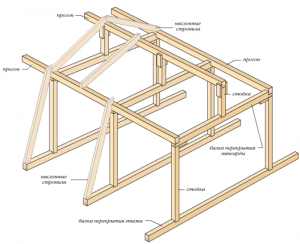

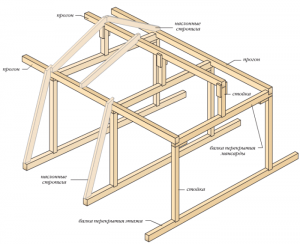

It is worth noting that the puff in this design cuts into the rafters and is fastened with self-tapping screws. It is possible to use a layered truss system on roofs with a changed slope angle. In the case of the use of layered rafters, the useful area of \u200b\u200bthe roof increases, which is convenient for the construction of attics.

The system with hanging rafters is a closed triangle, in the contour of which the rafters, as it were, stretch the beam.

Special notches are made on the beam to prevent the displacement of the rafter legs and the transfer of the load to the horizontal wall. The load remains only vertical, which is the key to the integrity of the roof and the building structure.

I would like to dwell a little on the system of rafters for a shed roof. It can be considered as half of a gable and the same installation rules apply.

But some points should be taken into account:

- Such a system is applicable for small buildings;

- In this system, a power beam is mounted, which is longer than any elements of a gable structure, therefore, a reduction in the width of the roof is required;

- Decisions must be made to support and reinforce the timber. In this case, a supporting leg can serve as an alternative to the brace.

These are perhaps the most common and simple ways of installation in the implementation of the issue - do-it-yourself truss structures.

Necessary calculations

Gradually revealing the topic of our article, we touched on the main points of choosing a material for a truss structure, its main elements and the most common installation options that can be easily done without the involvement of professional builders.

But the choice of material and type of truss system is not final at the roof design stage.

The main thing in this matter is to calculate the size of the rafter legs, which is carried out in several ways:

- selection of sizes according to the values of building codes;

- appeal to architects;

- making calculations on your own with the necessary knowledge.

When calculating the dimensions of the truss elements and the pitch of their location, the following are taken into account:

- roof type;

- type of roofing;

- slope angle;

- climatic loads.

After carrying out the calculations and determining the type of construction, the installation scheme of the rafters is carried out.

Collection of roof truss

A complete truss system includes:

- roof trusses;

- Mauerlat;

- side and ridge runs;

- diagonal elements.

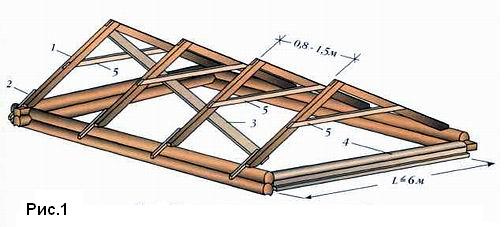

The most important in the rafter system are the structures of truss trusses, including truss legs and connecting elements - trusses.

The rafters and the connecting beam are made in the form of a triangle with equal sides. This design can withstand huge loads.

Roof trusses are assembled directly on the roof or on the ground, and then go up. The second option is more convenient for self-execution of the truss system device.

The truss truss consists of:

- grounds;

- rafter legs;

- crossbar;

- fasteners.

At the first stage of collecting the truss truss, it is necessary to cut the material to a given size. It is best to take bars with a section of 50x100 mm.

The fastening of the rafters at the top and on the base is carried out with capercaillie screws, in a joint. For better insertion of the screw into the rafters and to avoid the appearance of cracks in the attachment points, it is necessary to make a hole with a diameter slightly smaller than the diameter of the screw.

From the upper point of the attachment point of the rafters at a distance of 50 cm, the rafter legs are connected by a crossbar, which gives the truss truss rigidity and protects against deflection, the likelihood of which occurs especially in winter.

To fix the crossbar in the rafter legs, it is necessary to make cuts in half their thickness.The same notch is made at the ends of the crossbar.

Advice. The material from which the rafters will consist should be cut at a bevel so that the construction of the truss truss has an angle of inclination of about 40 degrees.

Roof truss installation

Rafter trusses are installed in the following order:

- First of all, extreme farms are installed;

- Then the installation of central trusses is carried out.

The device of the extreme trusses of the truss system has the following rules:

- The base of the truss truss is placed on the upper frame of a wooden structure or on the Mauerlat;

- First, several holes must be made in the base through which it will be attached to the frame;

- It is necessary to check the straightness of the placement of the truss truss using a plumb line attached to the crossbar;

- After determining the even establishment, the base of the truss truss is fixed;

- In order for the truss truss to be stable, it is necessary to fix jibs from the log house to the truss leg of the truss, the length of which is not of fundamental importance;

- Before tightening the jib with screws, the straightness of the installation is checked again.

As you can see, a do-it-yourself rafter system is a rather responsible process that requires knowledge of the basic rules for the construction and installation of a truss system.

When the installation of the outer trusses was successful, you can proceed to fixing the central truss and the subsequent ones, if any, in the design solution. Fixing is carried out at a distance of 1 m from each other.

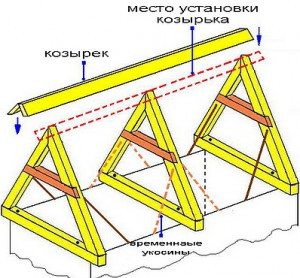

The central roof truss is reinforced with temporary braces. After mounting the visor, they can be dismantled.Central farms have the same fastening rules as the extreme ones. After the installation of all roof trusses, the crate is nailed.

Entrance to the attic

If the roof space will act as an attic space, then an entrance is being built in the extreme roof truss. For this, a door frame is made, for which bars of 50x50 mm are taken.

The arrangement of doors in the truss truss has the following order:

- the side racks of the door frame are fastened to the upper and lower crossbars and fixed with self-tapping screws;

- a restrictive bar is nailed along the perimeter of the door frame;

- the side racks of the box rest against the rafter legs;

- the upper crossbar is attached to the rafters with an end connection;

- the lower crossbar is fixed with screws to the base of the truss;

- after installing the box, the doors are mounted.

The practical implementation of installing doors to the truss truss and the entire truss system can be seen in the video.

Choosing the type of truss system for independent execution, it is necessary to decide what qualities it will perform in the future. The hanging truss system works in compression and bending. It rests on the load-bearing side walls and distributes the load of the roofing on them.

The sloping truss truss rests on the side and middle load-bearing wall, it works only for bending. This type of construction lightens the weight of the blood, therefore it is more common in modern construction, requiring high-quality roof arrangement.

The truss system is subjected to constant load, so when installing it on your own, remember that the strength and reliability of the structure depends on your professionalism!

Did the article help you?