Depending on what material was used in the construction of the house, in what geographical area and natural conditions it is located, they choose the shape of the roof and the methods of attaching the rafters - the main structural unit of the truss system that holds the roof on itself. Fastening the rafter system is a very important point in the construction of the roof frame, because even correctly performed calculations and selected material will not guarantee the reliability of the roof if the rafters are fastened incorrectly or poorly.

Depending on what material was used in the construction of the house, in what geographical area and natural conditions it is located, they choose the shape of the roof and the methods of attaching the rafters - the main structural unit of the truss system that holds the roof on itself. Fastening the rafter system is a very important point in the construction of the roof frame, because even correctly performed calculations and selected material will not guarantee the reliability of the roof if the rafters are fastened incorrectly or poorly.

Attaching the rafters to the wall can be done in several ways:

- with the help of a Mauerlat;

- with a puff and rafter bars;

- through floor beams;

- connection with the upper crown of log walls;

- using the strapping of a frame-type house.

There are two types of rafters - hanging rafters and layered. We will consider the types of hanging rafters, since they are usually used in the construction of houses with a large roof area.

Ways of fastening rafters

Hanging rafters have only one reference point - the wall, and this leads to the formation of expansion horizontal pressures in the entire rafter system.

Before attaching the rafters to the wall, it should be learned that in this case, to extinguish the expansion forces, a puff is used, which is a board or beam, through which the opposite rafter legs are connected together with a rigid connection of the tops of the rafters.

As a result, a non-thrust triangle is formed, which is connected to the wall of the building.

Sometimes, as an alternative to tightening, floor beams can be used, laid perpendicular to the walls in the same plane with the rafters. Typically like this fastening rafters to beams used in the construction of light attics.

It should be noted that regardless of the mass of the roof, it is better to connect the rafters to the beams with full confidence in the reliability of the walls of the house, since the load on the walls of the building created by the rafters will be point-like and will not be able to be distributed evenly like the case with fastening the rafters to the Mauerlat.

Floor beams for light roofs are chosen not thick, usually with a section of 5 * 15 cm.

Advice! To create a roof overhang, the beam must be chosen so long that its ends can be taken out of the walls for a distance of at least 55 cm on each side.

The rafter leg is also extended beyond the wall and attached to the edge of the beam.

How are rafters attached to beams?

If the rafter leg is simply attached to the beam, and then pressure is applied to the rafter, then its end will slide along the beam, and this can lead to the destruction of the roof.

Therefore, to stop sliding and securely fasten the rafters, the following types of connections are used:

- spiked tooth;

- tooth with an emphasis;

- stop at the end of the beam.

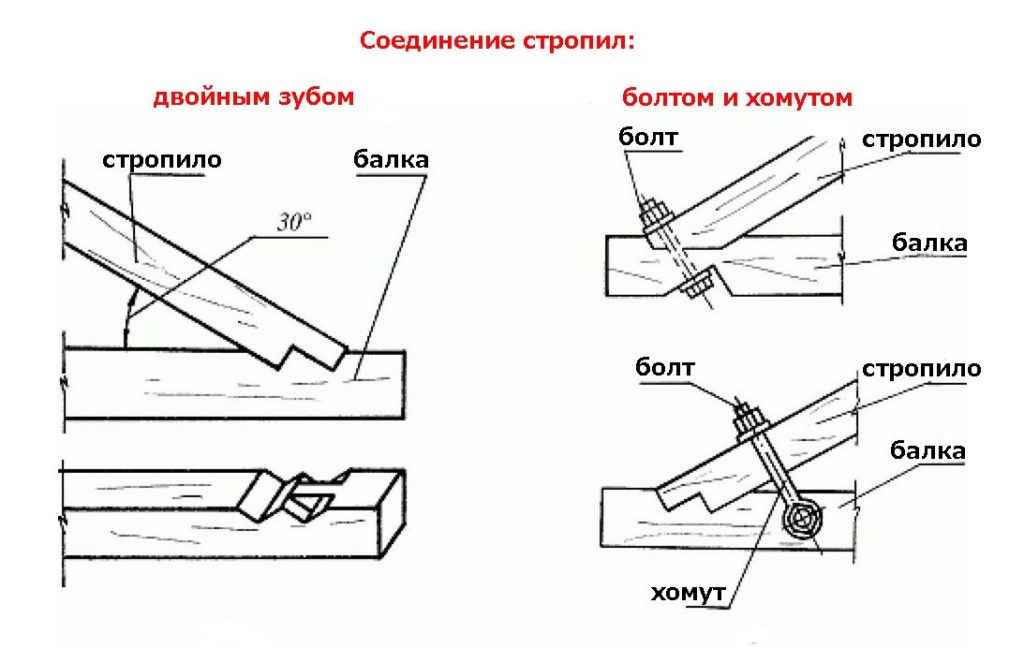

The connection is made using one or two teeth, depending on the angle of inclination of the rafter leg. Such fastening of the rafter with the beam ensures the transfer of the load from one roof element rafters directly to another element.

For fastening, in addition to this type of connection, metal corners for rafters are used.

Fastening by a notch with a single tooth is carried out according to the following rules:

- This type of connection between the rafter and the beam is used when the roof is steep enough, that is, when the angle between the beam and the rafter is more than 35 degrees.

- A tooth with a spike is made in the heel of the rafter, while an emphasis with a socket for the spike is cut out in the beam.

- The nest is cut down with a depth of 1/4 - 1/3 of the thickness of the beam. In order to prevent weakening of the beam, it is not recommended to cut to a large thickness.

- It is recommended to carry out the cutting at a distance of 25-40 cm from the overhanging edge of the beam. This will prevent the beam end of the house from being chipped by the pressure of the rafter leg.

- A single tooth is usually performed in combination with a spike that prevents the rafters from moving sideways. Such a connection is called a tooth with a spike and an emphasis.

If the roof is hollow with an angle of inclination of less than 35 degrees, the rafter legs are mounted in such a way as to expand the friction area with the overlapping beam, that is, to increase the bearing area of the rafters on the beam.

For this, a cut is made with two teeth in various combinations:

- in two spikes;

- emphasis with a spike and without a spike;

- in a castle with two spikes

and so on.

The first case involves cutting a spike with an emphasis under one tooth and an emphasis under the second. At the same time, an eye is cut out in the rafter leg for a spike with an emphasis on the first tooth, and in addition to it, an emphasis on the second tooth.

The depth of insertion of the teeth, as a rule, is the same, the same depth. When making cuts of different depths, the first tooth with a spike is cut by 1/3, and the second - by 1/2 of the total thickness of the beam.

In rare cases, such a very uncommon method of attaching rafters to a beam is used - like attaching to the end of a puff. .

In this case, a stop tooth is cut out in the leg of the rafter in such a way that one of the tooth planes lies on the very edge of the beam plane, and the second rests on the cut made in the beam. Washed down is made with a depth of 1/3 of the entire thickness of the beam, while the stop tooth is cut as far as possible relative to the edge.

Advice! To increase the reliability of connecting the beams to the rafters, they are additionally fastened using a rafter bolt or clamps, after which the entire assembly is attached to the wall of the building with iron strips or wire loops - a wall-mounted anchor bolt or crutch.

All types of connections in the design of the truss system are performed using metal products or wooden elements, called truss fasteners.

Among them:

- wooden products - bars, triangular overlays (kerchiefs) - plug-in or overhead to create a plate, spike, dowel;

- metal products - screws, nails, sets of bolts with washers and nuts, clamps, brackets, hinges, linings, various metal corners for fastening rafters, mechanisms for fastening rafters (sleds or sliders), toothed plates, anchors, nail plates, perforated tapes and others.

How to attach rafters to Mauerlat

There are two methods for attaching rafters to the Mauerlat:

- hard;

- sliding.

The type of interface is chosen depending on the design and shape of the roof and, accordingly, on the specific type of rafters used - hanging or layered.

The main principle of the rigid method of connecting rafters with Mauerlat is the complete elimination of the possibility of any influences (shifts, turns, bending, torsion) between both structural elements.

This result can be achieved in the following ways:

- fastening with the help of corners with a supporting hemming beam;

- by making a saddle (washed down) on the rafter leg, followed by fixing the resulting joint with staples, nails and wire.

The first case involves the creation of a support for the rafter legs on the Mauerlat using a support beam.

At the same time, the rafter rests rigidly along the pressure line, which is possible due to the hemmed beam up to one meter in size, after which a metal corner for the rafters is fixed on the sides in order to exclude transverse displacement.

The second method of attaching the rafter legs to the Mauerlat is used more often, and involves nailing the nails from the sides, at an angle towards each other (crossing occurs inside the Mauerlat), and then the third nail is hammered in a vertical position.

As a result, the attachment points of the rafters achieve high rigidity.

In addition, each of the types of pairing is insured by additional connection of the rafter legs with the wall of the building using anchors and wire rod.

Rafters of the same type, that is, having the same slope angle over the entire roof area, are prepared using a template in a uniform way.

Hinged or sliding pairing with two levels of freedom is achieved by using special fasteners that provide the possibility of free movement (within specified limits) of one of the mating elements.

In our case, this element is the rafter leg in relation to the Mauerlat. There are the following options for attaching rafters to the Mauerlat with the possibility of shifts:

- Execution washed down with subsequent laying of the rafters washed down on the Mauerlat:

- connection from the sides with two nails obliquely towards each other;

- connection with a single nail, nailed from above in a vertical position from top to bottom through the rafter leg into the body of the Mauerlat;

- as an alternative to nails - steel plates for attaching rafters with holes for nails;

- fastening the rafters to the Mauerlat with a bracket.

- The release of the rafter leg behind the wall with the implementation of a single fastening with mounting plates.

- Fastening with the help of special steel fasteners for rafters - the so-called "sled".

All of these methods allow the rafter leg to rest against the Mauerlat, however, when moving, the system has the ability to move relative to each other.

A sliding type pairing can often be found in the construction of houses. Especially such a technique for connecting rafters and Mauerlat is relevant for wooden houses built from timber or logs.

The gradual shrinkage of the walls of the building leads to a distortion of the original geometry of the house, and this, when using rigid mates, can lead to a violation of the integrity of the walls.

Thanks to sliding joints, log walls, gables, as well as the rest of the roof structure, can gradually adapt to shrinkage.

The assembly of the entire structure is carried out first on the ground. All measurements are taken, tie-ins are cut in the rafter legs and Mauerlat, after which they are carefully adjusted.

And then the rafter legs are fastened and other roof elements are installed on the building in order of priority.

Did the article help you?