The geometric shape and the material chosen for covering the roof determine the type of roof being erected. This article will talk about how to assemble the roof correctly, using frame technology, which allows you to create roofs of various shapes and use almost any material to cover them.

The geometric shape and the material chosen for covering the roof determine the type of roof being erected. This article will talk about how to assemble the roof correctly, using frame technology, which allows you to create roofs of various shapes and use almost any material to cover them.

The choice of frame roof design is carried out taking into account the planned loads of snow cover in the area where construction is being carried out, as well as the size of the structure being built.

There are two schemes for assembling frame roofs:

- Fermennaya;

- Frame.

A roof made using frame technology must meet the following requirements:

- The load created by snow masses and wind currents should be distributed along the walls of the house;

- All elements of the building frame must be protected from various precipitation;

- Sufficient space should be left in the attic for the installation of insulation in order to isolate the attic from warmer living quarters;

- Good ventilation of the attic space should be ensured;

- Sheathing of the roof frame and roof must have reliable protection against the effects of moisture and heat emanating from warm rooms.

How to properly assemble a roof

Before you properly assemble the roof, it should be borne in mind that the maximum value of the free span should not exceed 12.2 meters, and the largest distance between trusses or rafters should be no more than 60 centimeters.

When calculating the characteristics of the main elements of the frame of the roof assembled according to the truss scheme, parameters such as the width of the spans and the load of snow cover should be taken into account.

When assembling the roof, two options for rafters can be used:

- Free-standing rafters (free);

- Rafters that support the load of the ceiling of the attic space (loaded).

The cross section of the boards used to make ceiling beams and rafters must be at least 89x38 millimeters.

In the case of using heavy clay tiles, as well as attic windows, the roof frame should be additionally strengthened or the rafters should be calculated as loaded.

Also calculated as loaded rafters with a roof slope of less than 28º and a ratio between full span and rise in the ridge of 1:4, rafters.

When planning how to assemble the roof frame, it should also be taken into account that all connections between the roof elements are as reliable as possible.

It is also necessary to ensure the reliability of the support on the wall or Mauerlat (rafter beam) of the rafters themselves and the attic floor beams, while the rafters in the upper part are connected in pairs on the roof ridge board, the width of which should not be less than the length of the rafter support.

The cross section of the ridge board should not be less than 140x17.5 millimeters, and it is advisable to choose a width that exceeds the width of the rafter. The rafters on the ridge board are fastened opposite each other, preventing their displacement, while the rafters must intersect with the ridge and the Mauerlat at a right angle.

To attach the rafters to the upper part of the wall tie or to the Mauerlat, they are cut out, while the length of their support must be at least 38 millimeters. The support of valley and ridge rafters must be at least 50 mm, and the boards used for their manufacture must be at least 38 mm thick.

Important: shortened rafters (rafters) should adjoin the valley and ridge rafters at an angle of 45º, if we take the projection onto the floor plane.

For reliable roof protection of the walls and windows of the building from external influences, for example, precipitation, the rafters should be taken out of the outer limits of the walls at a distance of 40-50 cm, and in the case of wooden walls - by 55 cm.

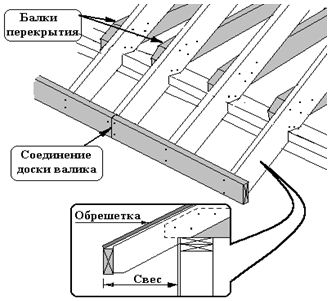

In this case, the ends of the rafters hanging outside the wall should be brought to equal distances beyond the boundaries of the wall and connected to each other in the end parts with a special board (roller).

Important: roller connection is not allowed on any other sections of the rafters, except for the end ones.

The thickness of the roller board should be at least 17.5 mm, but for convenience it is recommended to use boards whose cross section coincides with the cross section of the rafters.

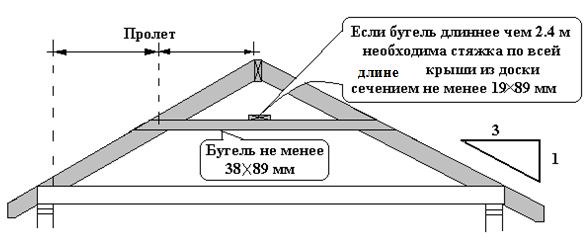

In the case when the slope of the roof is 1:3 or more, its estimated span can be reduced with the help of supports, yokes, as well as the use of additional supports for the ridge.

The cross section of the boards used for the manufacture of these elements must be at least 89x38 millimeters.

In the case where the roof slope is 1:4 or less, the load on the floor joists can be transferred from the rafters by means of diagonal braces and additional walls, and it is also necessary to install solid struts between the floor joists under these walls.

At the same time, it should be ensured that the floor beams do not sag by more than 2.5 cm when the design snow load is fully transferred.

In the case when the connection of opposite rafters is not made on the floor beams, and the angle of inclination of the roof does not exceed 1: 3, it is necessary to provide additional support for the ridge.

If the slope angle is greater than 1:3, this support is not required, it is enough to make a reliable connection node at the bottom of the rafter system.

To equip various communication systems of roof frame elements, various holes and cuts can be made in them, the location and dimensions of which must strictly comply with the same requirements that apply to the floor frame.

When assembling the roof frame, the crate can be made of materials such as chipboard, board, plywood, etc.The thickness of the material is selected depending on the distances between adjacent rafters, and in the case of sheet materials, on how the edges are supported on the timber roof frame.

The sheet materials used in the manufacture of the crate, in case of strict observance of the basic rules for the construction of frame roofs, make it possible to give the roof a more attractive appearance, as well as significantly strengthen its entire structure.

Quite widespread in the construction of frame roofs were boards made of wood chips, especially grade P-3.

DSiP without sanding and based on phenol-formaldehydes are also quite often used, one of the advantages of this material is their higher fire resistance than plywood and boards.

Below is a table that shows the dependence of the minimum thickness of the sheathing layer on the distances between trusses or rafters.

When erecting a frame roof, you should also ensure good ventilation of the attic space between the roof sheathing and the insulation layer.

This not only allows the insulation to perform its functions most efficiently, but also reduces the harmful effects of warm and humid air flows from the interior on the elements of the roof and its frame.

With correctly executed junction nodes, additional creation of wind ties is not required. Let us consider in more detail the structure of the construction of the most important components of the frame of the roof being erected according to the truss scheme.

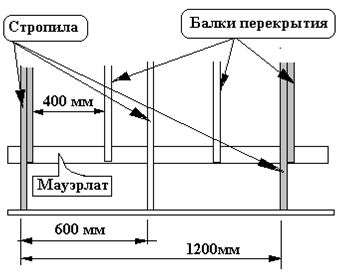

The distances between the floor beams and the rafters can be chosen differently, while it is necessary to ensure that the gaps between their joints are no more than 120 centimeters.

Various connections can also be used, which in any case should provide a sufficient amount of free space for laying insulation and organizing the air circulation required for ventilation of the attic.

Trusses and rafters can be supported both on the walls of the upper floor of the building, and on the Mauerlat board installed on the overlapping beams.

When the rafter support is displaced by a distance exceeding 5 cm from the floor beams, the second board must be installed on the Mauerlat in the same way as the installation on the upper wall trim.

The first Mauerlat board should be nailed to each of the attic floor beams with at least two nails of at least 82 millimeters.

Important: In the absence of a direct bundle of rafters and floor beams, it is imperative to install a strapping board.

With an equal pitch of floor beams and rafters, the most reliable connection is in the form of a double knot, in which a single Mauerlat board is used, while, in the case of sufficient insulation thickness, support should also be made on the upper wall trim.

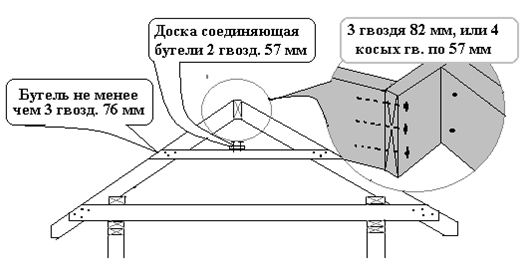

The rafters are fastened to the ridge on the reverse side using at least three nails of 82 mm, or from the side of the rafter using four nails of at least 57 mm.

The yoke located between the rafters is nailed to each of them horizontally with three nails at least 76 mm each.

The fastening of the rafter, that is, the shortened rafter, to the ridge or valley rafter is carried out using at least two nails of 82 mm.

Fastening to the rafters of the roof lathing, made of sheet material, is carried out in approximately the same way as the sheathing of the frame for overlapping.

When fastening the sheets, make sure that there is a gap of at least two millimeters between them, and if necessary, the support for their edges is made of boards with a cross section of at least 38x38 mm, the installation of this support is carried out similarly to the installation of floor spacers.

The arrangement of the roof frame for a building, the construction of which is made of concrete or brick, practically does not differ from the installation of the roof frame of a wooden house.

Roof frame it is connected to the wall using a Mauerlat, the best mounting option is to use anchor bolts with a diameter of at least 12.7 mm, the distance between which should not exceed 240 centimeters.

Useful: at the junction of the wall and the board, a layer of waterproofing material, such as roofing felt or glassine, should be laid.

The fastening of trusses to the upper wall tie is carried out similarly to the fastening of floor beams.

Useful information on the assembly of frame roofs

Here are some useful tips for assembling roofs:

- When erecting gable roofs of a large area and roofs with a large overhang without support, the use of trusses is considered the most convenient, and the scheme using rafters is more suitable for hip and multi-gable roofs. In addition, when constructing a building, both roof assembly schemes can be used together if necessary.

- When using trusses with a large span, it is possible not to equip the load-bearing middle wall by performing a “free” layout of the interior space of the house.

- Reducing the cross section of the boards used for the manufacture of rafters and elements that reinforce the frame allows not only to reduce the total weight of the roof structure, but also to reduce the total cost of its construction. In this case, you should choose the highest quality boards, reduce the distance between the rafters, and also use various connections to transfer the load from the truss system to the load-bearing walls of the building.

- When designing joints between floors and rafters, it is important to provide not only the possibility of free installation of a layer of insulation, but also its high-quality ventilation.

- It is also important to observe the distance between the upper part of the window opening and the horizontal plane of the spotlights.

- The angle of the roof slope must be chosen in accordance with the material used to cover it.

- In order to avoid calculating the amount of ridge lift, you should specify the angle of the roof in degrees, and not in the form of ratios.

- In the case when the roof is also a fence for the attic room, the rafters should be calculated according to strength parameters. For installation and ventilation of the insulation layer, it will be easiest to make an additional structure.

- If the operation of the attic space is not planned, then the possibility of strengthening the boards selected for the manufacture of rafters should be taken into account, since the load of the rafters cannot be transferred to the floor beams located freely in the span.

- The most attractive appearance of the assembled roof is achieved by using the same slope angles of all its surfaces.

- It is important to think in advance the economic efficiency of the operation of a particular roofing material when choosing it.Sometimes it is more cost effective to replace a roof that has reached the end of its useful life than to periodically repair a more expensive roof covering.

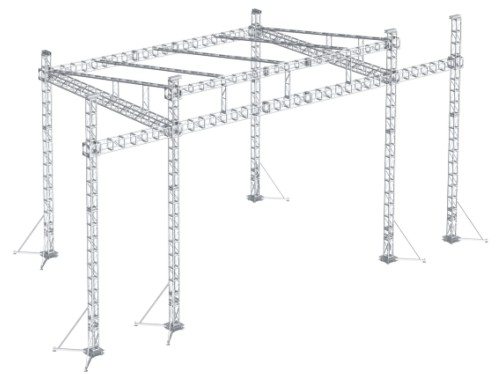

Fabrication and installation of truss structures

When constructing a structure such as double pitched roof, or creating a room for an attic, it is quite convenient to use a frame made of ready-made trusses, which can also be used in the construction of a roof in conjunction with a rafter system.

Trusses can be made in advance, and after the construction of the walls of the upper floor of the building is completed, they are simply installed in their places, after which the assembly of the roof frame and its coating with roofing material is carried out quite quickly.

Currently, there are special production facilities that manufacture finished trusses, the structural elements of which are most often interconnected using special metal connecting plates.

In addition, roof trusses can be made independently.

Farms should be installed so that the distance between them does not exceed 60 centimeters, and the nodes are connected using plywood, the thickness of which is from 10 to 12.5 millimeters.

In this case, the outer plywood layer should be laid parallel to the bottom board of the span. Truss elements are made of solid rafter boards, the cross section of which can be 140x38 and 89x38 millimeters.

Maximum value roof overhang depends on the section of the rafter board: with a section of 89x38 mm, the maximum overhang should not exceed 102 cm, and with a section of 140x38 mm - 142 cm. The size of the cornice can be increased by using the reinforced structure shown in the diagram.

In the connecting nodes, plywood is installed on both sides, after which it is evenly nailed (at least 76 mm) over the entire area of \u200b\u200bthe joint between the board and plywood. The ends of the nails protruding from the back are bent.

Useful: It is possible to use shorter nails, which must be hammered in on both sides to ensure proper fastening strength.

Did the article help you?