The installation of a modern type truss system is a very flexible process, capable of implementing even the most complex ideas in terms of roofing.

The installation of a modern type truss system is a very flexible process, capable of implementing even the most complex ideas in terms of roofing.

However, at the same time, increased attention should be paid to the installation of rafters, since the shape of the roof will depend on the correct installation of the truss system, which is the skeleton of the roof.

Rafter systems are complex and at the same time reliable, able to give an attractive appearance to both the roof itself and the whole house as a whole. Let's try to step by step analyze all aspects of the construction of the truss system.

Mauerlat device

The installation of the Mauerlat is where the construction of the truss system begins. Mauerlat serves as the basis for laying rafter legs, while ensuring uniform distribution of the load from the roof structure over the entire wall area.

It is a bar or a log hewn from the upper and lower sides, attached along the perimeter of the outer walls of the building.

Device options available truss system without the use of a Mauerlat, however, this entails some disadvantages from a constructive point of view.

Mauerlat allows you to provide increased rigidity of the truss systems without a high consumption of materials.

Before laying the mauerlat, the wall is insulated with a waterproof material - usually with two layers of roofing material.

The beam is laid on a reinforced belt with a slight indent from the outer and inner edges of the wall with the following preliminary preparation:

- For almost any occasion, a bar with a section of 100 * 150 mm made of antiseptic hardwood is suitable.

- The beam is preliminarily laid out from one pediment to another along the entire length of both walls.

- Next, the necessary measurements are made: the Mauerlat is laid out strictly according to the level, while controlling the uniformity of the distance between the bars, which should be equal along the entire length.

Next, proceed to fixing the beam to the wall. There are several methods of fastening, but one of the most reliable is fastening to a reinforced belt with anchor bolts.

Anchor bolts are strengthened in the reinforced belt during its pouring. Holes are pre-drilled in the beam for further landing of the Mauerlat on the anchor.

Advice! In order to achieve a perfectly vertical position of the bolts for fastening the Mauerlat, before pouring the reinforced belt, take a long, even board, attach it to the bolts and, using an ordinary square, give them a vertical position.

The prepared Mauerlat is placed on stands consisting of several planks, then the beam is lowered onto the bolts, taking out one plank from under it. After fitting on the bolt, a jumper is welded from a piece of reinforcement or a washer is screwed on.

After laying the Mauerlat, the construction of the truss system can be started directly.

Preparing for the installation of rafters

When attaching the Mauerlat to the wall, improvised means can be used for lifting. As for the work on the construction of the truss system itself, it is not possible without the use of construction mobile scaffolding.

Their use is necessary both for lifting rafters roof elements to the height required for installation, and as a working springboard for the installer and laying the required building materials.

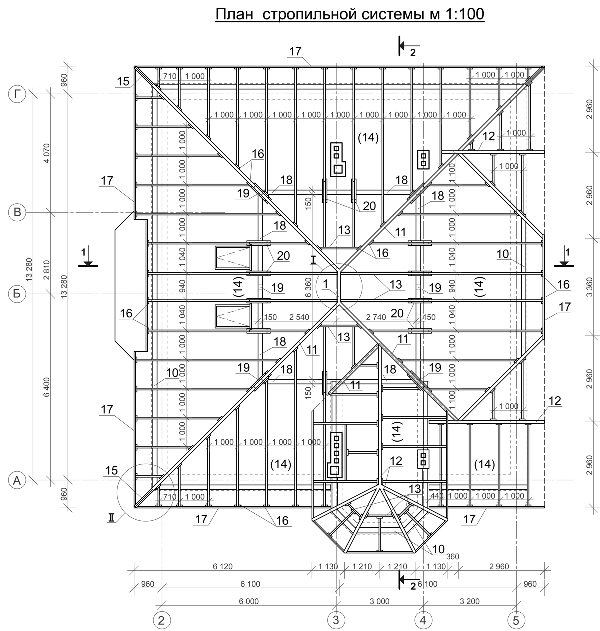

In addition, you will need to first complete the drawings of the truss system, according to which the work will be carried out.

Upon completion of the solution of safety issues and convenience of work at height, they begin the construction of the truss system.

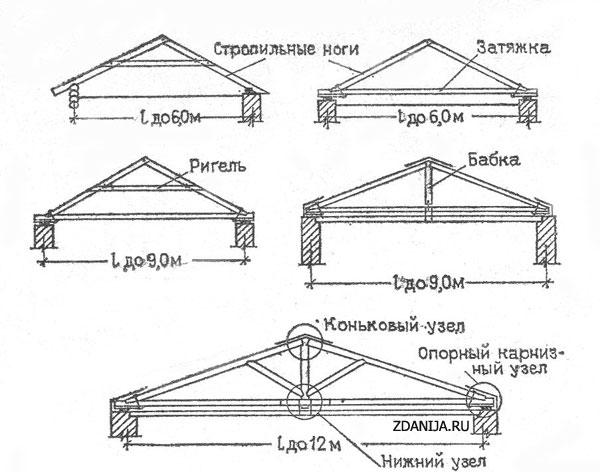

In the absence of an internal capital (bearing) wall in the building, that is, another support in addition to the outer walls, the building legs can only rest on the outer walls of the building. For this case, the use of the so-called hanging rafters will be required.

If anyone is faced with the construction of a roof for the first time, then we recall that rafters are called bearing and supporting structures of a gable pitched roof, rafter legs are inclined beams that form a roof slope, puffs (air ties) are a horizontal beam connecting rafter legs.

How to properly install rafters

As rafters, on average, a beam of 50 * 200 mm of the required length is used, however, for greater reliability, it is required to calculate the hanging rafters depending on the wind and snow load, the installation step of the rafters, and the type of roofing planned for installation.

The truss system device technology is as follows:

- With the help of scaffolding, two beams are raised to the roof.

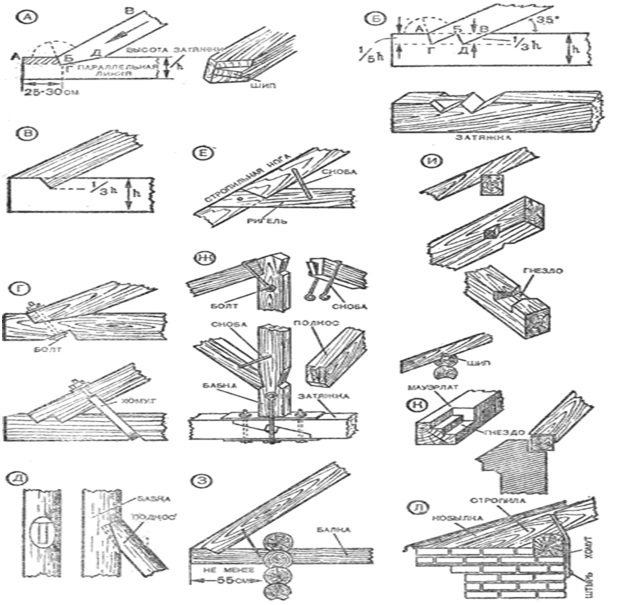

- The lower ends of the rafter legs are cut in such a way as to provide the rafter leg with a stable support on the Mauerlat. Rafter legs are marked so as not to confuse the side of their location.

- Install and attach their lower ends.

- Further, at the place of the upper junction of the rafters, the rafters are cut at the required angle so that when they overlap, they enter each other, forming a single vertical plane. Next fasten rafters between each other with nails. This connection is very reliable.

Advice! In order to properly perform the sidecut, the rafters must first be attached one to the other, draw the lines of the cuts with a pencil, and then cut the resulting sites to half the thickness of the beam.

- Further preparation of the rafters should be carried out already on the ground. To this end, they measure out and make a template, according to which all other rafters are prepared.

- Next, the installation of the truss system is carried out, expressed in the installation of rafters on one and the other side of the gable. Attach the rafters to the Mauerlat on a nail.

- The next pair of rafter legs, like the next, is to be made on the ground according to the template.

- Pull the thread along the ridge between the mounted pairs of rafters and proceed with the installation of the remaining rafters.

- The step of the truss system is chosen about 70 cm, which is usually the most optimal and reliable option. To do this, pre-mark the Mauerlat, and then mount the rafters according to the markup.

- It is imperative to adhere to the guideline in the form of a thread stretched between the side rafters, and, if necessary, to adjust the height of the rafter legs directly on the spot. In rare cases, you will need a lining under the legs of low planks.

- The width between pairs of rafters is adjusted in the lower part according to the marks on the Mauerlat, and in the upper part - using a temporary board with identical markings. In other words, after the installation of each rafter pair, a board is temporarily nailed from above to the left and right rafters according to the previously applied markings, which are copied from the Mauerlat.

- With a significant distance between the bearing walls, the hanging truss system must be strengthened with puffs (horizontal timber). The rafter pairs are pre-connected with a horizontal board in the area of \u200b\u200bthe ridge, thereby forming a ridge knot.

- Puffing with a large distance between the supporting walls can be carried out from several boards that are connected to each other. The manufacture of such a puff (the so-called.barking) will help in solving such problems as achieving the required length of a structural element, as well as obtaining its greater strength and reliability in comparison with a single beam of similar thickness. The boards are to be cut to the required length, fastened with nails, twisted with nuts and studs with rafter legs.

- The distance between the puffs must be constantly monitored: it must be identical to the distance between the rafter legs. For this purpose, narrow boards can also be used, which are placed according to the markings on the Mauerlat.

- Also, using the board, you should connect the skate and the puff. In the absence of a retaining wall, the puff may bend under its own weight. To avoid this, it is connected with the help of a “headstock” to the ridge of a rafter pair.

All of the above must be done with all rafter pairs.

Building rafters for overhang device

The design of truss systems may not include a cornice overhang. Therefore, it will most likely have to be erected after installing the entire rafter system.

For the installation of a roof overhang, the rafter leg must be built up with a board called a "filly". Departure or cornice overhang is necessary to drain rain and melt water flowing from the roof.

In addition, the overhang protects the walls from getting wet and mold. The length of the overhang must be at least 40cm. The best option is considered to be an overhang of about 60 cm in length.

For the manufacture of an overhang, boards of the desired length will be required. The width of such boards may be narrower than the width of the rafter legs.

The filly is attached to the rafter leg with a small gap, which is partially filled with an insert in the form of a shorter board.Fastening is carried out with the help of nails: two of them are hammered from the opposite side and bent.

Such a fastening will be quite enough, since the load on this node is planned to be small.

Advice! A good option is also to use a beam of rafter legs of such a length that is enough to take out the cornice overhang.

The rafter legs, originally fastened to the nail, now require final fixing to the Mauerlat beam. For this, the so-called shank, which is a strip of metal, can be used.

They wrap the rafter leg with a shank on both sides - on the left and on the right relative to the rafters, and to a depth of 25-30 cm from the inside of the walls they fasten it to screws and nails.

Additional fastening of this kind will protect the roof from a possible breakdown during strong gusts of wind.

You can also use the old proven method - wrapping the rafter leg with wire, fixed in the same way from the inside of the walls. In this case, a wire 4-6 mm thick is used, tied to ruffs driven into the wall.

On this, the installation of the truss system can be considered completed. The roof, built in accordance with the rules described in the article, will be a reliable support for the roofing arranged above, which will not be afraid of any weather whims.

Did the article help you?