The final stage in the installation of the roof can be called filing cornice overhangs. Without this operation, the roof will not only not acquire a finished look, its functionality will be incomplete. Not only for beauty, but also for additional protection, filing a roof for your home is necessary. It is performed after the external insulation of the walls of the building.

The final stage in the installation of the roof can be called filing cornice overhangs. Without this operation, the roof will not only not acquire a finished look, its functionality will be incomplete. Not only for beauty, but also for additional protection, filing a roof for your home is necessary. It is performed after the external insulation of the walls of the building.

Backing options

If you do not first insulate the walls of the house, the sheathing work will not only become more complicated, but the result will not be as high quality. Especially if the filing will be carried out on a horizontally sewn box.

A box installed before the insulation of the walls of the house will not allow the insulation to be brought to the very top of the wall, which is fraught with significant heat losses in the future.

Note! After the rafters are installed and the crate is mounted, the rafter ends are cut strictly in a straight line. Make sure this line is parallel to the wall of the building.

Roof frame future sheathing is sheathed with boards or drywall. Usually, the rafter ends are cut vertically, then their ends are also sewn into a common box.

When preparing, hemming the roof, the first board of the crate is laid along this straight line. As for the design of the box, there are two main types of it.

However, it all depends on the individual characteristics of each roof, so the design may be slightly modified if necessary.

- One of the options can be called filing along the rafters, with an angle corresponding to the slope. In this case, elements called soffits will be attached to the rafters parallel to the walls. To do this, you need to create a flat plane of the bottom of the rafters. It is easiest to align the rafters in one line using boards or beams screwed with screws with a section of about 4 × 10 cm. The first and last boards are aligned and attached. Then the threads are pulled, and the rest of the bars are fixed along them. Where two slopes meet, the bars are attached to the corner rafter on both sides.

For this option, a roof structure with a small angle of slopes is suitable. For more complex roofs or roofs with steep slopes, the second cladding option is more often used.

- Starting from the edge rafters, and then a horizontal box is drawn up to the wall. The frame, as in the first case, it is advisable to make boards or timber. Attach one edge of the board to the bottom of the rafters, the other is attached to an additional beam attached at the junction of the rafters with the wall.In the corners of the junction of two slopes, the board is laid flat, the future joint will pass from the angle of the descent of the slopes to the angle of the descent of the two walls. In the end, a solid structure independent of the wall should be obtained. This technology for manufacturing a frame for hemming a roof is considered the most popular. For greater strength, fastenings on screws are reinforced with steel corners. After the frame is completely ready, you can begin to perform roof cladding work.

Materials and sheathing method

Since the roof is hemmed not only for beauty, but also for reliable protection, the choice of material should be taken quite seriously.

Rain, snow, wind, as well as birds, cats and insects must not penetrate under the roof covering. Otherwise, they will not only bother you, but will also render the structure unusable ahead of time.

Note! It is especially important to protect an uninsulated roof. After all, the installation of a cold roof is no easier than installing a roofing pie for a dwelling.

The simplest and most popular material for sheathing is considered to be ordinary lining. But this material must be processed before work.

roof elements sanded, impregnated with an antiseptic and varnished. All this will prevent premature decay of the material.

You can use vinyl siding - also quite popular due to its durability and low price. But in its elements there are no holes for ventilation.

Manufacturers do not recommend doing them on their own, and the appearance of the roof finished with it will not be as spectacular and expensive as many would like.

Galvanized steel elements are perforated, relatively inexpensive, but often begin to rust due to excessive accumulation of condensate.

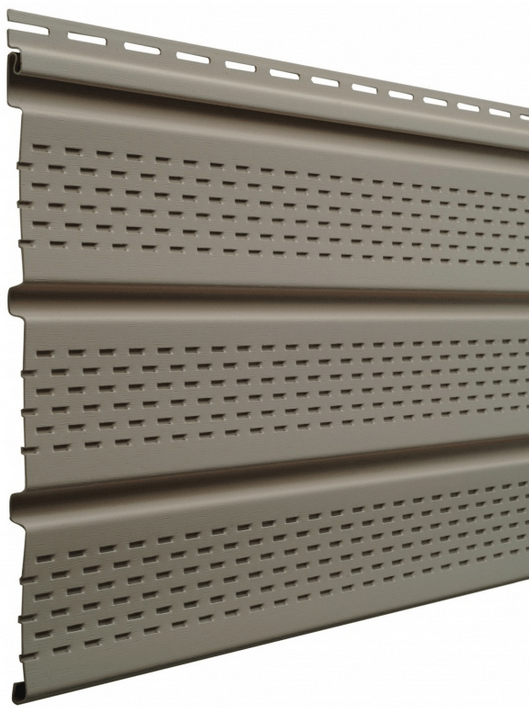

Vinyl spotlights are also perforated, have a large selection of colors and tolerate humidity and temperature changes well.

Aluminum finishing materials do not rust, look great and are very durable. Provided with ventilation holes, resistant to compression and expansion, easy to install.

If you are already familiar with the technology of building a roof, then you will make its sheathing easily and without problems.

- The frontal board is sheathed with a combined cornice chamfer, where its upper edge is inserted into the profile with a gap of about 3 mm.

- Soffits are attached across the cornice line.

- Soffits are inserted either into the J-profile, or into the J-chamfer, or into the F-profile from the side of the facade board.

- From the side of the walls, the spotlights are inserted into either the J-profile or the F-profile.

- If the overhang of the cornice is more than 45 cm wide, the soffit is fixed in the middle. It is attached either to a wooden filing, or to an additional support bar.

- Soffit panels are cut at an angle at the corners of the cornice overhangs. Either J-profile or H-profile is used.

Did the article help you?