If you think that a do-it-yourself polycarbonate greenhouse is the lot of specialists, then this review will convince you otherwise. You can assemble the structure on your own in a fairly short time, and you do not need to be a jack of all trades. You need to be able to use a screwdriver, tape measure and metal scissors, as well as carefully follow all the recommendations outlined in this article.

- Description of the main stages of the process

- Stage 1 - planning and drawing up a drawing

- Stage 2 - purchase of necessary materials

- Stage 3 - collecting the right tool

- Stage 4 - construction of the foundation

- Stage 5 - assembling the frame of the greenhouse

- Stage 6 - fixing polycarbonate

- Care instructions

- Conclusion

Description of the main stages of the process

Now let's go directly to work, I will not tell you about all the advantages of polycarbonate, a lot has already been written about them. I will not deal with possible design options, as I will talk about a specific solution - a greenhouse made of a metal profile for drywall, it seems to me the simplest and most rational today.

Another important advantage of a home-made greenhouse over a finished one is the ability to determine the optimal dimensions yourself based on your site and needs. That is, you do not adapt to the design, but it is made in such a way that it is convenient for you.

Stage 1 - planning and drawing up a drawing

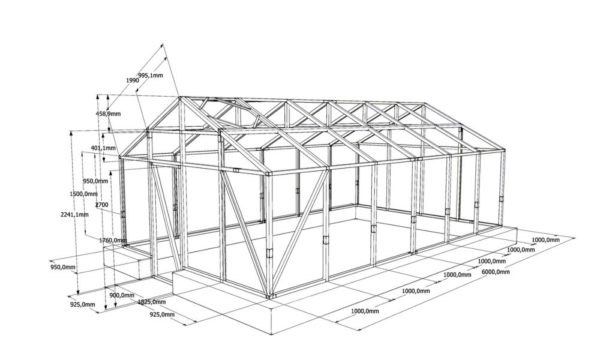

First of all, we need to decide on the parameters of the future building and its design, without which we will not be able to make a project, buy materials and carry out preparatory activities.

We need to do the following:

- First, decide for what purposes you need a greenhouse and how you are going to use it. Often people don’t even know why they need to build such a structure and do it as they have to, and already in the process of using it they understand that they had to do it wrong, and if they had spent an hour studying the information and analyzing it, they would have avoided many problems;

- Next, you need to figure out how much space you have and where it is best to place the greenhouse. I won’t talk about illumination, everything is clear here anyway, the main thing for you is to take measurements in order to select the optimal parameters.If the design takes up half the yard and closes the passages to the garden, then nothing good will happen, it should be such that it does not interfere with you and your loved ones;

- After the initial calculation has been carried out, you need to decide on the design of the greenhouse, there are two options - a semicircular and a gable roof. I will not describe them, I will only say that the gable version is also more convenient in operation due to the greater overall height, and it is easier to heat it due to the configuration features, so I advise you to choose it;

On forums and websites, I often hear the opinion that the arched structure is much better due to the fact that it is much easier to fix drywall on it. Like, he bent and screwed it, but in a gable it needs to be cut and measured. But after all, you don’t need to constantly assemble and disassemble the structure, you are not building a greenhouse for speed, so it’s better to spend an extra hour, but in the end get a more rational option.

- Now you can sketch the future greenhouse, do not worry about accuracy, the main thing for you is to determine all the dimensions and sketch the final result, when you see it, you will be much better at solving all the questions that arise. When working, consider one nuance - the width of the polycarbonate is 2.1 meters, the length of the sheets is 6 or 12 meters. Select all the parameters so that there is as little waste as possible, and the sheets are joined on the racks, and not between them;

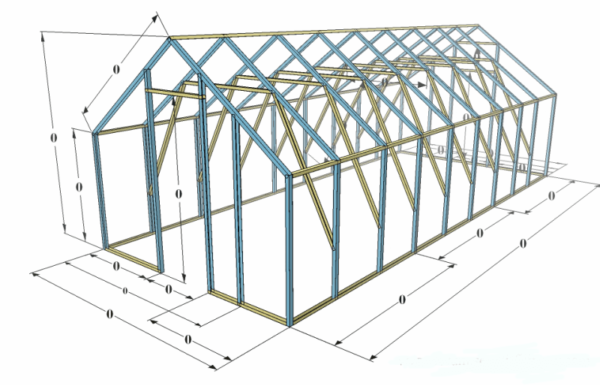

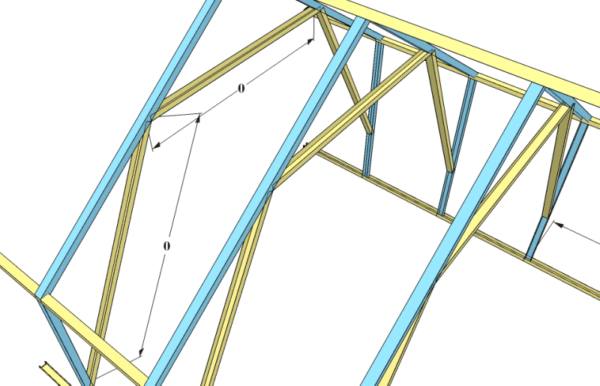

- As you can see, the construction of a polycarbonate greenhouse on a metal profile frame involves a large number of spacers.Thanks to them, the strength of the frame increases significantly, and you do not need to worry about wind and snow loads. If desired, you can put spacers on the vertical sections, it all depends on the size of your structure and the quality of the profile used;

- The final drawing is done. Where possible, you set exact dimensions, where it is difficult to calculate, you can mark approximate ones, anyway you will act according to the situation and you can always correct certain parameters. The main thing is that the main parameters are determined and all important elements are marked, this will allow you to avoid errors during assembly and not waste time solving a particular problem..

Stage 2 - purchase of necessary materials

When you have a sketch in your hands, it will not be difficult to calculate the required materials, which is why it was necessary to clearly define the design at the previous stage. The main list is presented in the table below.

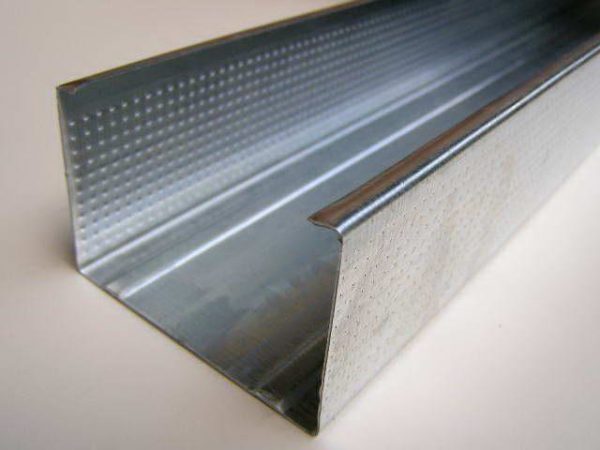

| Material | Selection Guide |

| Metallic profile | We will use 50x50 mm rack elements and 50x40 mm rails. Only metal products with a thickness of 0.6 mm or more should be used, they have sufficient strength for our purposes, the length of the products can be 3 or 4 meters, choose a more convenient option. The price of a standard three-meter profile is about 200 rubles for the main one and 190 for the guide |

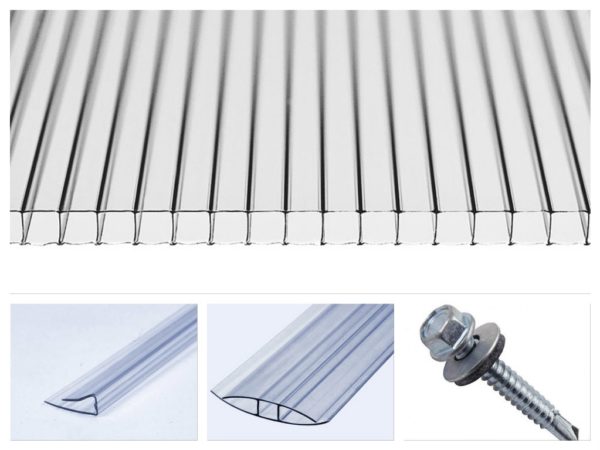

| Polycarbonate | I recommend not to take the most budget options with a thickness of 4 mm, but to take a sheet of at least 6, and even better, 8 mm at all.Such material is much stronger and much more durable, besides, the greater the thickness of polycarbonate, the better it retains heat, which is also very important in our case. As for the cost, a sheet 6 meters long and 6 mm thick will cost you from 3,500 rubles |

| fasteners | A very important part of the process, as it is impossible to make a strong greenhouse without fastening it securely. To connect the profiles, self-tapping bugs are used, for fastening polycarbonate - special roofing screws with rubberized washers, and to fix the structure on the base, you will need anchors or hex screws. Butt and end strips for polycarbonate are also needed |

| sealant | In no case do not connect polycarbonate without treating its end part (with voids) with a sealant, not a single plank provides complete protection, and over time, dirt will accumulate inside the cavities. Any clear weatherproof compound will work. |

In addition to all of the above, we need material for the base of the greenhouse, there can be three options:

- Wooden beam of sufficient section;

- Brick from which the foundation is being built;

- Concrete that is poured into exposed formwork.

The choice of a specific solution is up to you, below I will talk about each of them in more detail.

Stage 3 - collecting the right tool

It is impossible to carry out work without a tool, so if you are going to assemble the greenhouse yourself, you need to have a certain set of tools on hand:

- In the process of work, you will have to tighten a lot of self-tapping screws, so you can’t do without a screwdriver.Ideally, if you have it equipped with a set of nozzles, because you will need different options: for PH2 self-tapping screws, and for roofing fasteners, a special 8 mm bit. Make sure in advance that all the equipment is there, otherwise you will have to stop work and go to the store;

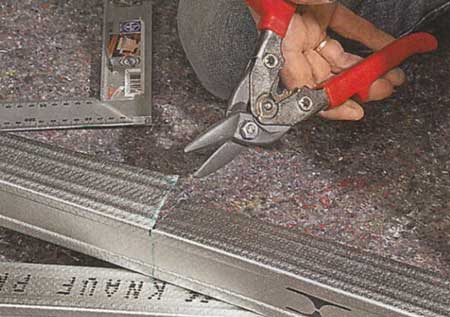

- The easiest way to cut a profile is with ordinary metal shears. You don't need expensive equipment, you can easily do the job. Personally, I use only hand tools for such purposes, it is convenient and costs ten times cheaper than the same grinder or jigsaw;

- To carry out various measurements, we need a tape measure, its length must be at least 5 meters so that you can do the work at a time, and not measure the elements in pieces. I recommend buying options with a web width of 25 mm, they are much tougher and last many times longer;

- To cut polycarbonate, it is easiest to use a regular construction knife with a 25 mm wide blade (it is hard). We also need a felt-tip pen or marker for marking and a level or rail for cutting along a perfectly straight line. It is better to take a long level, since we will use it both when setting up the base and when assembling the greenhouse;

Stage 4 - construction of the foundation

In order for our greenhouse to stand as strong as possible and be securely and evenly fixed, it is necessary to build a foundation, above I wrote about the main options, now I will talk about each of them separately.

A wooden frame is good because it will cost you the cheapest, but its durability is the smallest - from 5 to 10 years. Another advantage of this solution is the possibility of installing it in another place, it will not be difficult to remove such a base, and this is very important in some situations.

As for the instructions for the construction, it is very simple:

- For work, we need a bar with a section of 100x100 or even more, this option is highly durable. You can take thinner elements, but they are less reliable;

- Next, you need to impregnate the beam with a protective compound, for this you can use drying oil, special compounds, mining and much more. Some even use hot bitumen, as it seals the pores on the surface and prevents moisture from penetrating into the wood. Processing is best done several times for maximum efficiency;

- When the elements are dry, they can be installed in their future location and leveled. Bricks, concrete tiles and other solid elements can be placed under the beam, so the base is perfectly level;

- As for fastening, the elements can be connected to each other using corners, you can cut the corners, it all depends on you. If you want to fix the base in the ground, then you need to drill through holes in several places and drive reinforcement or metal pins through them. And you can, as in the photo below, build columnar supports made of bricks and attach the timber to them.

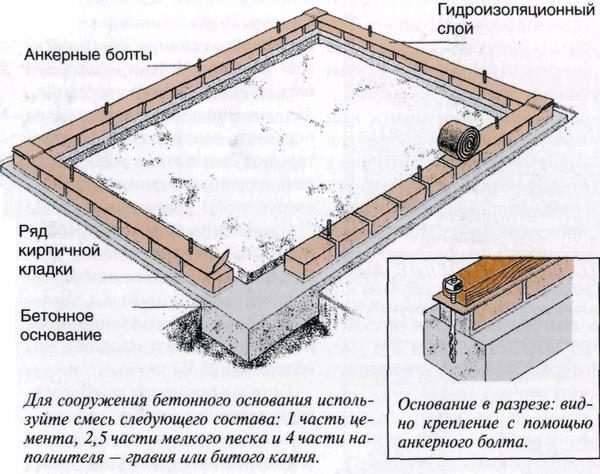

Now let's deal with the construction of brick and concrete or one concrete, they are similar and differ only in the upper part, you can make the foundation solid to the very top, or you can put one or more rows of bricks. A detailed diagram is shown in the figure below.

As for the technology, it is quite simple:

- First of all, the site is marked and the cord is pulled around the perimeter of the future structure. This is not a bar of the same size, here you need to set the corners and measure out the diagonals to make sure that you have an even and not skewed foundation;

- Then a trench is dug about 30 cm deep and the formwork is set up, its height depends on whether the brick will be laid on top or you will get by with one concrete. The solution is poured into the formwork, how to prepare it is written in the diagram above, everything is very simple and at the same time reliable, do not forget to pull the cord along the level to immediately level the solution;

- If there are bricks, then after the concrete has hardened, laying is done, if there are none, then you can immediately waterproof the upper part with roofing felt and attach a wooden block to it or immediately put up a greenhouse.

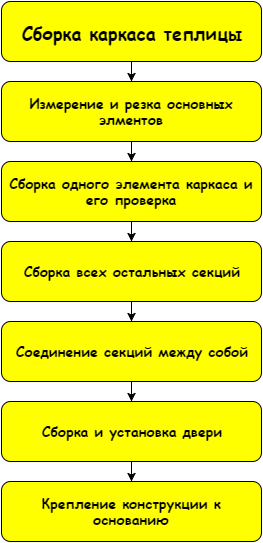

Stage 5 - assembling the frame of the greenhouse

Then you can proceed to the most critical part of the process, since we carried out the design ahead of time, we have a ready-made and detailed project in our hands, which will be our main guideline in our work.

Do-it-yourself polycarbonate greenhouse construction is carried out in the following sequence:

- To begin with, we need to cut pieces of the profile for the end blind section, the dimensions of the side and ridge elements will be known exactly, and the spacers can be measured and cut after the main nodes are aligned. Everything is really simple, and you yourself can easily figure out the process, do not rush to assemble, first lay the entire section on the ground to make sure everything fits and matches;

- Then you need to fasten four elements: two side racks and roof slopes. We will get the outline of the future structure, it needs to be aligned in terms of level and diagonals, after which we can accurately determine the length of the spacers. One of the options is shown in the diagram below, as you can see, if you miss the spacers a little - it's okay, you can fix them in a different place or change the angle a little;

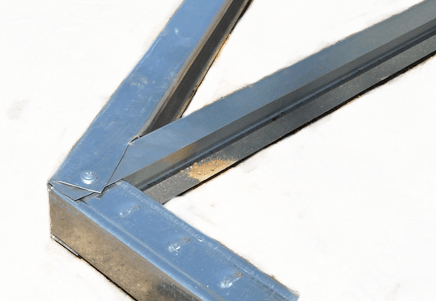

- Next, the entire section is assembled, since we make the end element first, it will be with additional racks. Such separate parts are called trusses and are assembled from many parts, it is easiest to work by putting the knot on the ground, the profile is twisted together with self-tapping bugs so that the caps do not stick out above the surface, you can use the option with a press washer;

- At the location of the element roofs and racks, you can connect three elements at once, if you have a transverse stiffener in this place.Everything is simple here, an example of just such a connection is shown in the photo below, if the connections do not match, then fasten them as it turns out;

- After assembling one section, you must take measurements and make sure that it is even and corresponds to the drawing in its parameters. If everything is fine, then you can cut the elements to all other farms according to this sample and then assemble them on the stream. Everything will pass quickly, the main thing is not to confuse the elements anywhere and constantly check the geometry of each of the parts;

- The door for the greenhouse is made simply: a frame of the required size is assembled, hinges are attached to it and jumpers are placed for rigidity. Polycarbonate can also be immediately fixed to the canvas. Subsequently, you need to install a valve, I recommend this option, as in the photo below - simple and reliable;

- When all the trusses are ready, they need to be assembled together, it is better to involve one, and preferably two assistants, so that they hold the parts of the structure in the process of connecting them. The first section must be set strictly vertically, you can fix it with supports, the second section is attached to it with the help of crossbars, and so on in order, do not forget to constantly monitor the level;

- When the structure is fully assembled, it should be fixed to the foundation, for this, anchor bolts are used, which are screwed through the profile. In the end, you should get a strong and even frame that can withstand even significant loads.

If after assembly you find that the structure is not as reliable as you would like, then simply strengthen it with additional spacers, fixing them will not be a problem, but the frame can be very well strengthened without any alterations.

Stage 6 - fixing polycarbonate

Now you can proceed to the final stage of work - the installation of polycarbonate, the process is simple, but requires special care and attention:

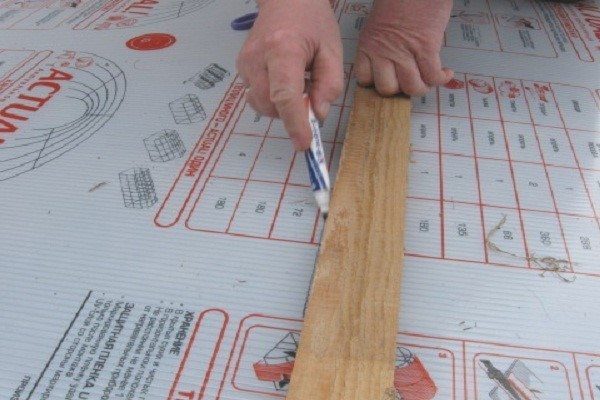

- To begin with, measurements are taken to determine the exact parameters of each element. After that, the polycarbonate is marked, the protective film does not need to be removed from it, it is removed only after fastening. Draw the dimensions of all the pieces you need with a marker or felt-tip pen, it is important not to make a mistake, as you can ruin the material;

- After that, the material is cut, for this a rail or ruler is placed along the line, pressed tightly, and the upper layer of the material is cut with a knife. It is important here not to rush, so that the knife does not go to the side, and carefully cut the polycarbonate. After cutting the line, the sheet is simply bent and cut from the reverse side, everything is very simple and easy, you will do this job once and you will cope with it quickly;

- Fastening is quite simple: the sheet is leaned in the required place and carefully fixed with the help of special roofing screws with rubber linings on washers. It is important to position the fasteners evenly so as not to push through the material, so that you understand this aspect, below is a diagram that shows the correct and incorrect fastening;

- You need to put on a special bar on all end sections, I wrote above that it is best to glue it on silicone, it fills the voids and holds the element well. The second option is to use a special tape, the ends are pasted over with it, and after that the bar is put on, it also turns out very reliably and efficiently, the only negative is the rather high price of the tape;

- As for the connecting strip, it is put on the side of the first sheet before its installation, and the second is inserted into it as a guide. If it is impossible to insert the second piece from the end, then you need to bend the bar with a spatula or knife and fill the polycarbonate into it, everything is very simple and fast, no additional fastening is required;

- The step of placing self-tapping screws is 30-40 centimeters, they are placed along all stiffeners, the less polycarbonate dangles, the better. Fasteners should be located no closer than 2 cm from the edge, so as not to damage the structure. If necessary, you can add a few screws in the right places;

- After assembly, you can walk around and check the tightness of all joints, if you find gaps, then they can be sealed with sealant, it adheres well to the material and provides good protection.

Home-made greenhouses in their reliability most often surpass finished products made of polycarbonate, because you do not save on materials and strengthen the structure as needed.

Care instructions

In order for your building to last as long as possible, you need to follow a few simple recommendations:

- In the summer, the structure does not need special care, except that dirt is periodically removed with a wet rag or a regular hose with water;

- If the temperature inside the greenhouse is too high, then you can shade it very simply: prepare a solution of water and chalk and spray it on the surface outside. When you need to remove the shading, then simply wash off the chalk with water from the hose;

- After harvesting in the autumn, the main part of the care work begins. First of all, it is necessary to free the greenhouse from plant residues, it is desirable to disinfect the soil, there are many options, use the one you like;

- Next, you need to thoroughly wash the structure both outside and inside, for this it is best to use a hose with a spray gun, but if it is not there, then you can use a sponge or soft cloth and a Fairy type dish detergent solution. Do not even use plastic brushes, they can damage the surface;

- Inspect the frame of the greenhouse annually, if corrosion has appeared in some areas, then it must be treated with a rust converter and painted over with a special anti-corrosion paint. Timely work will eliminate the destruction of the structure, and you will not have to redo it;

- Then you need to disinfect the greenhouse, the easiest way to do this is with a sulfur bomb. An iron container is placed in the middle of the space, in which a checker is placed, then it is set on fire, and you should quickly leave the greenhouse - the smoke is very poisonous.Close the doors and vents tightly, if any, and do not open them during the day, that is how much time must pass so that all pests are guaranteed to die;

- After that, the greenhouse must be closed for the winter, if it is located in the country, then it is advisable to put supports under the farms so that they are not deformed by the weight of snow in winter. Of course, polycarbonate can also be removed for the winter, but this is a troublesome business, any carelessness will damage the polycarbonate. If you still need to remove the material, then remove it only from the roof, there is still no load on the walls and you do not need to touch them;

- If the greenhouse is on your site, then you do not need to disassemble it, but in winter, if necessary, you will have to remove snow from time to time. This should be done very carefully, in no case with a metal shovel. Only plastic is suitable, and then, try not to touch the surface, you can tear off the screws.

This is how the care instructions look like, there is nothing complicated in it, and, in fact, you need to devote 1 day to work in the fall, the rest of the time you need to make sure that nothing damages the structure, and if suddenly a separate piece of polycarbonate is damaged, then you can just replace.

Conclusion

A do-it-yourself polycarbonate greenhouse is not a fantasy at all and is not the lot of serious craftsmen with extensive experience. I know several people who, with no experience and only my advice, were able to get the job done.Of course, they periodically called me when problems arose, and I advised them, but if you suddenly have a problem, write in the comments below, I will explain everything to you in detail.

I recommend watching the video in this article, it shows the important points of the workflow, and if you see them visually, you can understand the topic much better, trust my experience.

Did the article help you?