Do you want to know what useful performance properties polycarbonate has and how it differs from other polymers? My accumulated experience allows me to reveal all the areas of application of the material, the rules for cutting it and how to attach it to metal and wooden frames.

Physical Properties

Key material properties:

- Heat resistance: melts at 280-310 °C. The ignition temperature is above 500 °C. Polycarbonate begins to soften at 130-150 degrees;

- Mechanical strength: according to this parameter, polycarbonate bypasses quartz glass by 200 times, acrylic (plexiglass) - by 6-8;

Of the transparent materials produced on an industrial scale, polycarbonate is the most impact resistant.

- Transparency: 4 mm thick cellular polycarbonate transmits 94% of light in the visible range. At the same time, it scatters light, forming soft lighting without a clear source;

Polycarbonate is of great value as a material for homeownership fencing. He will not allow passers-by to show inappropriate curiosity: only the approximate outlines of objects behind the fence are visible through the honeycomb panels, without any small details.

- Flexibility: it persists down to -100 °C. On the practical side, this means that polycarbonate can be installed at any time of the year and in any climatic zone. The minimum bending radius of a monolithic sheet depends on its thickness:

| Sheet thickness, mm | Minimum allowable bending radius, mm |

| 1 | 200 |

| 2 | 300 |

| 3 | 450 |

| 4 | 600 |

| 5 | 750 |

| 6 | 850 |

| 8 | 1100 |

| 10 | 1500 |

| 12 | 2500 |

- Density: monolithic polycarbonate has a density of 1.2 t/m3. The density of the honeycomb material due to the air cells in it varies from 80 to 120 kg/m3;

- Heat and sound insulation: in honeycomb material, it is provided by air cells-honeycombs. The greater the thickness panels (and, accordingly, the size of the cells), the less heat and noise the sheet passes through;

- Durability: correctly (read - with an ultraviolet filter up), the installed polycarbonate serves for at least 20 years. The exception is an inexpensive material made in China: trying to throw the most affordable product on the market, manufacturers save on the ultraviolet barrier. As a result, the sheet begins to crumble after 3-5 years of operation;

- Chemical resistance: polycarbonate is resistant to acid solutions (with a concentration of up to 10%), all types of fuels and lubricants, ethyl alcohol, detergents and fats of animal and vegetable origin.

Damage to the surface of the sheet can:

- Alkalis and their concentrated solutions;

- Acetone;

- Ammonia;

- Methyl alcohol.

When they hit polycarbonate, it becomes cloudy, and with prolonged exposure, it softens;

- Safety: over the entire range of operating temperatures (from -100 °С to +130 °С), polycarbonate does not emit any harmful substances into the atmosphere. When destroyed, neither sheet nor honeycomb material forms sharp fragments.

Areas of use

Monolithic

Monolithic sheet polycarbonate has a standard size of 205x305 mm. The length can be increased at the request of the customer, but the width is constant: it is determined by the dimensions of industrial extruders.

It applies to:

- Construction of LAF (small architectural forms) - kiosks, pavilions, etc.;

- creations canopies, windshields, visors;

- Installation of translucent facades;

- Glazing of balconies and loggias.Polycarbonate is favorably distinguished from glass by its low price, impact resistance and much better thermal insulation qualities;

- Installation of translucent partitions;

- Creation of translucent inserts in the doors.

Opaque polycarbonate with the addition of dyes is widely used for the manufacture of housings for consumer electronics (including cell phones). Here, its transparency for radio waves in combination with viscosity and impact strength are in demand.

Cellular

Cellular polycarbonate is used in the same areas as monolithic (with the exception, of course, of electronic device cases). But not only. Its heat-insulating qualities make it possible to use the material to create inexpensive and durable greenhouses and greenhouses.

cutting

What can cut the material into parts of the desired size?

Fastening

How to fix polycarbonate to a metal frame (for example, when sheathing a greenhouse or installing a canopy)?

The sheet is attached:

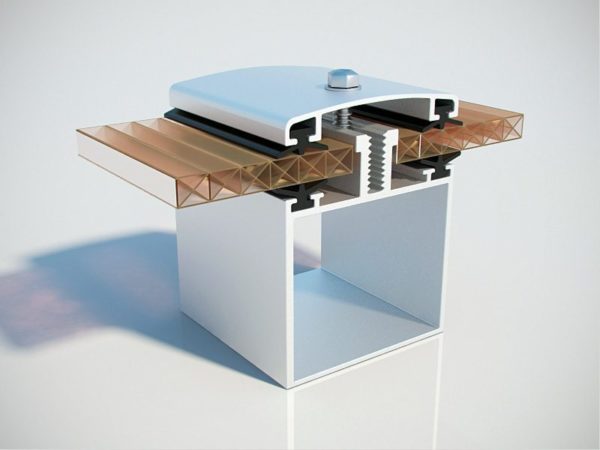

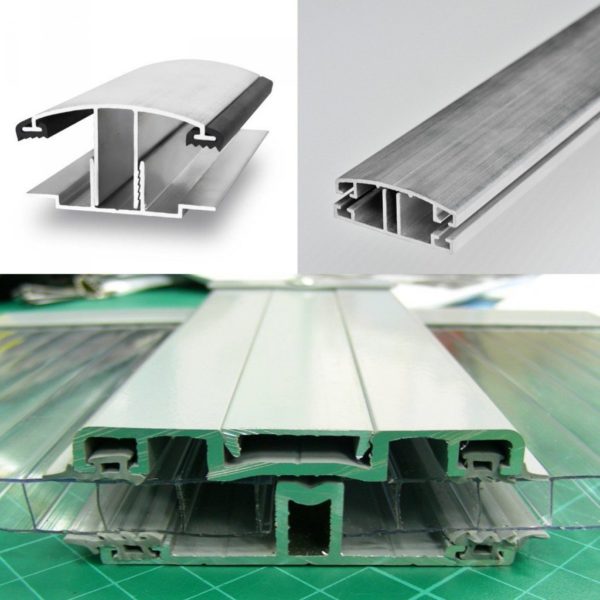

- End and connecting profiles (collapsible and non-collapsible). Profiles not only fix the sheet, but also protect against water and dirt ingress into the honeycomb cavities;

- self-tapping screws for metal with thermal washers.

Sometimes they are replaced with fasteners with rubber press washers.

Usually these fastening methods are used in parallel: the ends of the sheet are inserted into the profile, and the polycarbonate is fastened to the metal frame over the entire area of the sheet with self-tapping screws with thermal washers.

What does the fastening of polycarbonate to a wooden frame look like? Yes, exactly the same. There are only two differences:

- Self-tapping screws are used for wood, not for metal;

- Polycarbonate can be screwed to a tree not only with a screwdriver, but also with your own hands, using a Phillips screwdriver.

There are few subtleties in this work:

- Close edges. Without them, cellular polycarbonate will very quickly begin to look untidy: dirty streaks and mold will appear in the cells;

- Attach to frame. They can be used as self-tapping screws for metal, and can only be held at the ends of the sheets;

- Seal. For the reliability of the end or connecting strip, polycarbonate should be smeared along the edge of the sheet with silicone sealant;

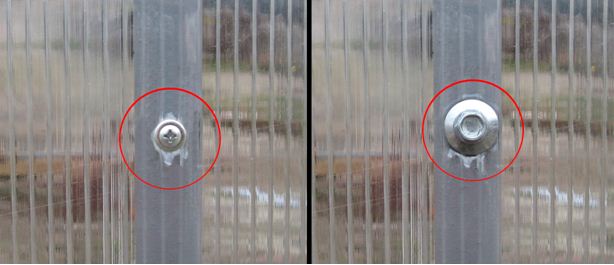

- Use a drill. Be sure to drill the polycarbonate at the attachment point. The diameter of the hole should be slightly larger than the diameter of the thermowell leg;

- Use hardware. Fasten the polycarbonate with galvanized (stainless) self-tapping screws. This instruction is designed to save you from unkempt rusty streaks;

- Use thermal washers. Do not use fasteners without heat or pressure washers. Over time, the material will crack in the attachment area;

The fixing point must be at least 40 mm from the edge. Otherwise, there is a risk that the polycarbonate pressed by the fasteners will crack along the honeycomb.

Conclusion

As you can see, polycarbonate has a lot of advantages and is extremely easy to install. To learn more about this wonderful material, the video in this article will help you. Looking forward to your additions. Good luck, comrades!

Did the article help you?