If you are interested in information on the topic: "Shinglas roof installation", then this article is for you. In it, we will tell you how to properly and in what sequence this type of roofing material is laid, what it is in general and where it is used.

If you are interested in information on the topic: "Shinglas roof installation", then this article is for you. In it, we will tell you how to properly and in what sequence this type of roofing material is laid, what it is in general and where it is used.

Shinglas roofing is a development of TechnoNIKOL corporation specialists, it is a flexible bituminous tile specially designed taking into account all the factors that affect reliability.

The roof material ideal for difficult climatic conditions in Russia and Ukraine.

The coating consists of the following layers:

- The upper protective layer of basalt dressing.

- Improved bitumen layer.

- Fiberglass base.

- bituminous layer.

- The lower one is a self-adhesive frost-resistant bitumen-polymer mass.

- Protective layer of removable silicone film.

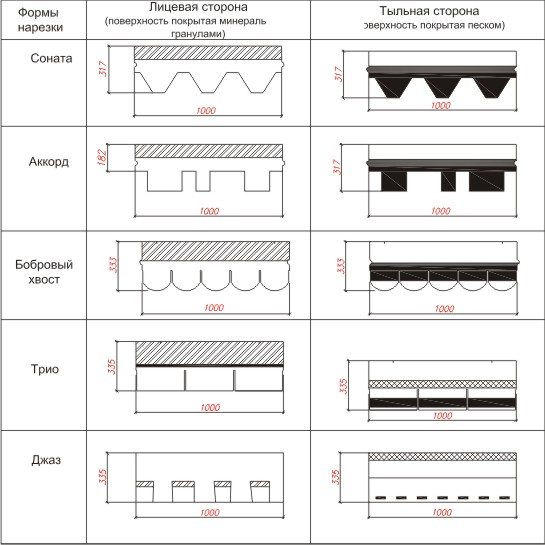

According to the shape of the cut and size, shinglas roofing is divided into 5 types:

- Accord - 317x1000 mm;

- Sonata - 317x1000 mm;

- Tango - 333 × 1000 mm;

- Trio - 333 × 1000 mm;

- Jazz - 336 × 1000 mm.

The material is produced in various colors, which allows you to create a unique design of the roof and the entire site, in general. You can make the roof both monophonic and multi-colored. For skates and cornices, special cornice tiles are produced.

Its size is 250x1000 mm. It is used as a whole for the cornice, for skates it is cut into three parts: 333x334x333 mm.

The scope of flexible blood is different. It can be residential buildings and industrial buildings.

Used for both renovation of old roofs, and to cover new buildings in any regions of Russia and Ukraine, even in the northern regions. What are the advantages of this material?

There are many of them, we list the most important:

- Profitability. When using this type of material, there is practically no waste left, even if the roof of a complex structure is covered. Also, flexible tiles perform the role of not only roofing material, but also heat and sound insulation.

- Resistance to chemical acids and biological organisms, as well as to ultraviolet radiation. The material does not lose color throughout the entire service life, and therefore does not require additional painting.

- The flexible tile is not subject to rotting and corrosion. Completely waterproof and not afraid of sudden changes in temperature. Handles both heat and cold well.

- The light weight of flexible tiles does not weigh down the roof structure, the installation of a flexible roof does not require special tools, the involvement of special construction equipment, a large number of people and, in principle, is not complicated.

- Due to the elasticity of this material, any irregularities are not afraid of it, it is especially convenient if the roof has a complex configuration. It can be used for any roofs, regardless of their slope.

- Service life of 25 years.

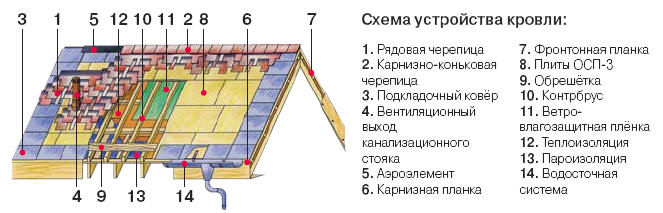

Now for the roof structure.

Roof device

Shinglas roofing is not only a roofing material. In order for the roof to be warm and reliable, it will be necessary to put several layers, in other words, to make a “roofing cake”.

It will consist of several layers:

- Control grid. A solid crate is attached to it. The second function of this layer is the creation of a ventilated under-roof space.

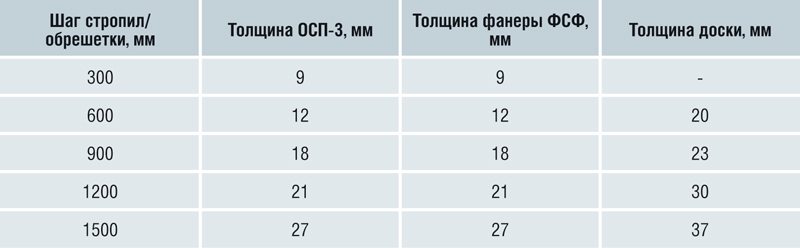

Crate. Subsequent layers are laid on it. The crate is made continuous. For these purposes, you can use edged boards made of coniferous wood, at least 30 mm thick (to withstand the weight of a person).

The most commonly used OSB boards or moisture resistant plywood sheets. In general, the thickness of the lathing depends on the shape of the roof, permanent and temporary

Advice! Since the tree tends to expand, it is recommended to leave a gap between the boards no more than 5mm, between OSB boards 3mm. All wooden surfaces must be treated with a special protective solution before laying, which will prevent the wood from rotting, protect against pests and make the wood less combustible.

- Next comes the underlayment. For these purposes, rolled bituminous material is used. If the roof is laid on the old coating (roofing felt), the lining carpet is not needed.

- End carpet. It is laid in places where the roof adjoins vertical surfaces and on roof breaks.For this, bitumen-polymer materials are used, which will act as waterproofing.

- Front and cornice strips. As is clear from the names, one is attached to the ends of the roof, and the other along the overhang of the eaves. They protect the edges from moisture and wind, the cornice strip reinforces the cornice.

- After that comes a layer of shinglas - a flexible roof, or as it is also called an ordinary tile.

Here is such a roofing pie device that should be at the roof when using a flexible roof. Next, consider the sequence of work.

Roof installation

First you need to take care of the availability of all materials and tools. How to calculate material consumption? To do this, you should know that in the package of jazz shingles, taking into account overlaps, the output is 2 m2, in other types - 3 m2.

Waste for this type of roofing material varies from 5% to 15%. Roofing nails will require 80 gr/m2. For different sections consumption mastics for the roof not the same: ends - 100 g / m2, valley - 400 gr/m2, junctions - 750 gr/m2.

Advice! Regarding mastic, the saying you can’t spoil porridge with oil does not work. Do not be zealous and waste material.

- Preparing the base for the roof. The crate is made continuous. A gap of no more than 5 mm is allowed for edged boards, for linear expansion of the material. The crate is fastened with self-tapping screws or brushed nails.

- Next, you should take care of ventilation. What does it mean? Three conditions must be met. First: there must be openings for the inflow of outside air. To do this, when sheathing the cornice overhang, use soffit strips or make ventilation grilles.Second: there must be exhaust holes. Here you can use the following options: for a closed inter-rafter space - ventilated skates, for an open one - point aerators. Third: there must be channels for air circulation in the under-roof space. For roofs with a slope of less than 20 degrees, the height of the channel will be 50mm, for roofs with a slope of more than 20 degrees, this value will be 80mm.

- Lining carpet. Depending on the angle of the roof slope, it may be solid or be located only in places of alleged leaks. So if the angle is more than 18 degrees, the rolled bituminous material is laid only along the ends of the roof, at the junctions (30 cm up the vertical surface), around pipes and windows. With a smaller slope, the roof is covered entirely from the bottom up with an overlap (in width - 10 cm, in length - 15 cm). The edges of the overlaps must be smeared with bituminous mastic, the lining carpet itself is nailed with roofing nails at intervals of 20 cm. When partially laying the substrate, the following rules should be observed: on the valley, the width of the carpet should be 1 m (50 cm on each side), at least 40 cm on the cornice overhangs and ends, around windows and pipes.

- On top of the lining layer along the ends of the roof and the eaves, with the help of nails, metal strips are attached. This is done with an overlap (5cm). A flexible cornice tile is laid along the overhang. This is done in a joint, on top of a metal bar, with an indent from the place of inflection of 1-2 mm. The protective silicone film is removed from the underside, after which it is glued, and then each tile is fastened with nails.

- A valley carpet is laid on the valleys and on the breaks of the roof.It is fastened with nails, the edges are smeared with 10 cm of bituminous mastic.

- Now you can lay ordinary tiles. Work starts from the bottom edge, gradually rising up. When laying the first row, it should be found on the cornice tiles almost completely (leave 2-3 mm). You should strictly follow the pattern, the excess is cut off from the ends. Then the edges are 10 cm glued with bituminous mastic. Roofing nails are used to fasten the tiles, they are nailed to each tile.

- Next, junctions are made, and ridge tiles are laid. After laying the substrate and ordinary tiles, it is recommended to cover the junction with a metal apron in order to avoid leakage. The ridge tile is laid with the short side along the slope, with an overlap of 5 cm and nailed, 2 for each tile on both sides.

Shinglas flexible roofing is a high-quality and sought-after material. It is easy to use, such a roof, if properly installed, will last a long time, be warm and will not leak.

Did the article help you?