The most popular roofing materials are valued for their high performance, but in order to find out which coating is ideal for your home, you need to determine all their pros and cons. From the right choice

what is better metal tile or corrugated board, depends on the life of the entire structure.

Note!

Roofing materials should be selected taking into account their properties and characteristics applicable specifically to your conditions.

- metal tile

- Decking

- Application of materials

- metal tile

- Decking

- Feature Comparison

- Advantages of a metal tile:

- Disadvantages of metal tiles:

- Advantages of corrugated board:

- Disadvantages of corrugated board:

- Protective coatings

- Layers of metal tiles

- Types of corrugated board coatings

- Classifications

- Classification of corrugated board based on:

- conclusions

- similarity

- Difference:

metal tile

Metal tiles are steel, aluminum or copper sheets for pitched roofswith a protective polymer coating. Profiled by the method of cold pressure, the metal tile looks like a ceramic tile.

Metal tiles are made on automatic lines from rolled sheet metal 0.4-0.7 mm thick with a protective and decorative coating with polymers of various colors (up to 50). Profiling rollers create a wavy profile.

The metal tile is classified according to the height of the wave and the distance between the waves, and the higher the wave, the stronger and more beautiful the material. Therefore, often the choice: corrugated board or metal tile - which is better, is decided in its favor.

Decking

Decking is a profiled sheet of galvanized steel obtained by cold rolling. To increase rigidity, it is given a wave-like or trapezoidal shape, which brings it closer to a metal tile, eliminating the difference: metal tile or corrugated board.

Over its 20-year history, corrugated board has won the trust of all builders:

- steel, stiffeners give the roof, ceilings and walls strength;

- corrugated board is sealed and does not weigh down the structure.

Profiled flooring differs in sheet thickness, wave height and the distance between them. The overall size and usable area are also taken into account. For example, brand s-10 means that the height of the rib is 10 mm.The corrugated board is covered with varnish, paints, enamels in accordance with the RAL and RR tables.

Application of materials

metal tile

Ordinary metal tiles are used in a slightly aggressive environment with a temperature of -50 - +50 °. But it is also available with special ultra-resistant coatings. During installation, it is necessary to protect the places of holes and cuts by painting, using special self-tapping screws with neoprene gaskets.

It was first used in Finland more than half a century ago. Since then, developers have been deciding whether metal tile or corrugated board is better. Today metal tile is the most popular roofing material around the world and in all climates.

Decking

Polymer-coated corrugated board is obtained by cold rolling.

The difference between metal tiles and corrugated board is that it is used for:

- roofing (especially the unique transparent polycarbonate decking);

- fences;

- load-bearing structures;

- lining;

- fixed formwork for the foundation.

Feature Comparison

Advantages of a metal tile:

- lightness - 1 sq m weighs 5 kg, and ceramic - 40 kg and slate -15 kg, so you can use inexpensive and light rafters, and the entire system as a whole;

- the sheet is made of mild steel coated with a layer of zinc, a primer and a protective color polymer, flexible and resistant (for example, polyester up to 30 microns thick or polyurethane up to 50 microns thick);

- steel contains alloying elements that increase its strength;

- tiles made of aluminum or copper are less rigid than steel, but more resistant to corrosion and will last over 100 years;

- metal tiles are environmentally friendly;

- a wide range of colors and types;

- fire safety;

- roofing installation and repair technologically simple and low-cost: it is possible to lay on the old flooring, as well as corrugated board. This is what makes it difficult to choose which is better - corrugated board or metal tile.

Disadvantages of metal tiles:

- noise from rain and wind: during installation, it is necessary to lay sound insulation (thermal insulation);

- the need for drainage due to sound insulation;

- the need to paint holes and cuts to avoid corrosion;

- the need for thermal insulation due to increased thermal conductivity.

Advantages of corrugated board:

- ease of installation;

- the ability to eliminate uneven roofs and walls;

- corrosion protection;

- protection against mechanical and chemical influences (especially with a polymer coating);

- reliability and durability;

- breadth of color schemes;

- light weight will allow the use of rafters of a small section - the pressure on the walls decreases, as well as financial costs;

- corrugated board and metal tiles are fireproof.

Disadvantages of corrugated board:

- uncomfortable amplification of sound from raindrops (as in a drum) requires laying mineral wool for sound insulation;

- corrosion on damaged coating.

Protective coatings

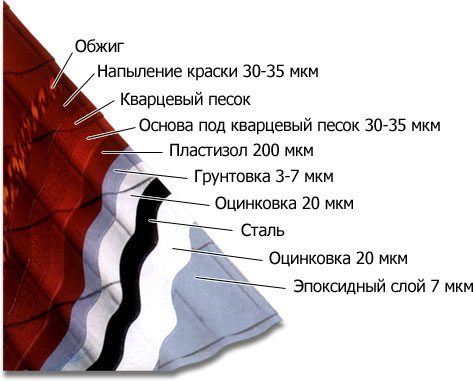

Layers of metal tiles

Protective metal coating for metal tiles can be:

- zinc - it will ensure durability;

- aluminosilicon,

- aluminum-zinc,

- iron-zinc,

- other types of coating based on the latest technologies are also typical for corrugated board, which complicates the choice: corrugated board - metal tiles.

Polymer one- or two-sided decorative coatings of metal tiles are:

- polyester - economical, but wear-resistant against moisture and chemical influences;

- plastisol - strong to mechanical damage and durable, but with temperature changes they can exfoliate;

- polyurethane - resistant to wear, corrosion and ultraviolet rays;

- acrylic - glossy, matte;

- polyvinylidene fluoride with increased anti-corrosion and strength in a humid climate.

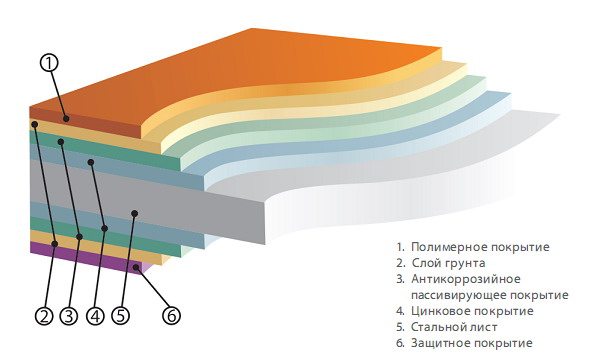

Types of corrugated board coatings

Galvanized steel with a corrosion-protective coating applied to it - paint and varnish or polymer.

Types of polymers for coating profiled flooring:

- polyester - PE;

- acrylic - AK;

- polyvinyl chloride - PVC;

- polyvinylidene fluoride PVDF;

- PUR polyurethane.

Classifications

Metal tiles by profile type:

- "Monterrey";

- "Super Monterrey";

- "Maxi"

- "Elite";

- trapezoidal.

Letter designations:

P - profile; Mnt - type "MONTERREY"; 1180 - width in mm; 3000 - length; 0.5 - thickness; LKPTs - galvanized sheet with organic coating; Pe - polyester coating; C - one-sided coating; RAL 3007 - color according to the RAL catalog.

Glossy, matte, embossed or metallic metal tiles with an optimal thickness of 0.5 mm are most in demand now, and PVF2 coating will provide maximum durability and color fastness.

Classification of corrugated board based on:

- Profiled steel sheet without protection - the coating is subject to corrosion, therefore it does not find external use.

- The pro-thinned-out flooring steel hot-dip galvanized.

- Hot-dip galvanized steel sheet with a decorative coating.

- Profiled sheet copper, chromium-nickel or aluminum, the most durable, but expensive.

- Profiled flooring with textured embossing, bent or perforated.

Profiled flooring is distinguished:

- by scope - roofing and wall,

- according to the shape of the corrugation - trapezoidal or wavy,

- by wave height: for fences, walls - 8 - 21 mm and over 44 mm - for roofing,

- distance between waves

- in metal thickness - 0.4 - 1 mm.

Marking

- H - the most durable corrugated roofing, especially with a wave of 44 mm.

- C - decorative for walls, fences and partitions with a wave of 35 mm.

- HC - universal for roofs and walls with a wave of 44 mm.

conclusions

similarity

Metal tiles and corrugated board are the most valuable roofing materials that have common advantages:

- ease of installation and operation;

- strength and reliability;

- ease.

Difference:

- in aesthetic terms, the metal tile is more effective: it imitates prestigious tiles, but is more expensive than corrugated board;

- the metal tile will last 30 years, but after 15 it will require cosmetic repairs - painting the places of damage, and corrugated board with a wave of 18 mm will last without repair for 45 years at a moderate cost;

- for metal tiles, the slope of the roof must be at least 12 degrees, while for corrugated board it will be only 7 degrees.

Obviously, taking into account all the advantages of these materials, you can easily choose the most successful option for yourself: corrugated board or metal tiles.

Did the article help you?