Many builders prefer roofing made of profiled sheets and their subspecies imitating metal tiles, non-ferrous metal roofing, as well as seam roofing made of rolled or sheet steel, which are distinguished by ease of installation and low price. In this article, we will tell you what kind of iron on the roof the modern market offers and how to properly carry out roofing work with it.

Many builders prefer roofing made of profiled sheets and their subspecies imitating metal tiles, non-ferrous metal roofing, as well as seam roofing made of rolled or sheet steel, which are distinguished by ease of installation and low price. In this article, we will tell you what kind of iron on the roof the modern market offers and how to properly carry out roofing work with it.

Getting to know the materials

Before you cover the roof with iron, familiarize yourself with the parameters of metal materials that contribute to practical and convenient roofing.

For example:

- Steel is ordinary iron, which has a low price.This durable material is resistant to physical impact, but the resistance to corrosion reduces its service life.

- Galvanized iron is more durable than ordinary iron, as the protective zinc coating protects the steel from corrosive processes. If, in addition, galvanized iron has a polymer coating, it is more resistant to external influences and has an attractive appearance. The materials with such a coating include corrugated board, a type of which is a metal tile.

- Recently, non-ferrous metal roofing materials (aluminum, copper, zinc-titanium) have become popular, which make the roof covering reliable, simple and architecturally expressive.

This is a brief description of roofing materials, the basic basis of which is metal.

Attention. Technical conditions for the implementation of sheet metal roofing imply the arrangement of a roof with a slope of more than 20 degrees.

Preparatory stage

Before covering the roof with iron, it is necessary to pre-prepare the material (sheet steel).

To do this, a layer of lubricant is removed from it, treated with drying oil enriched with dyes. After drying, such processing makes it possible to determine the location of the untreated areas and repeat the coating.

When using materials with a polymer coating, it is necessary at the preliminary stage to take care of the correct transportation of the material so that there are no scratches and chips on the surface.

Along the edge of the sheet iron, it is necessary to bend a technological fastening element - a fold (lock).

There are such types of fold:

- recumbent;

- standing.

They can be used for both transverse and longitudinal connections. The metal tile does not need such a connection, the sheets are overlapped.

To make a fold, you will need the following tools:

- workbench with a fixed steel corner;

- calipers;

- metal hammer with a flat side face;

- wooden mallet;

- comb bender;

- metal scissors;

- ruler.

The principle of making a fold

With the help of a workbench and a caliper, you can make a recumbent fold, which is very important in the question of how to properly cover the roof with iron.

A sheet of iron is placed on the edge of the workbench and the edge line is marked. The sheet must be held so that displacement does not occur.

According to the mark, the corners of the edge are bent with the help of a mallet - a beacon bend is obtained, which allows for precise further work. When the bend is made along the entire length of the edge, the iron is turned over and the edge is bent to the plane of the sheet.

Another sheet is prepared in the same way, which makes it possible to connect them together. To close the connection points are fixed with a hammer. The necessary scar gives the longitudinal edge.

Basically, the manufacture of a standing seam on the very roof similar to lying down. In the manufacture of a lock for ordinary sheets, a comb bender is used.

Mounting technology

Iron for the roof can be prepared within the workshop, but the installation of sheets is carried out on the site itself. It is necessary to make prefabricated elements (pictures) from steel sheets. This will make it easier to work at height later on.

Meter iron blanks are connected along the long side with the help of pre-prepared recumbent folds. There must be at least two sheets in the prefabricated element on the short side. The maximum size is the height of the roof slope.

On the roof, the workpieces are connected into a common plane using a standing seam. For the base coating, the prefabricated elements must be laid out in stripes.

In this case, a certain direction is observed and the bend is fixed between the sheets. During installation, it is necessary to check the correct location of the sheets relative to the vertical line.

After the stage of unfolding and connecting the paintings is completed, it is necessary to seal the joints with a steel strip and a hammer.

Advice. Bend over the ridge so that the edge bend on one slope is 6 cm, and on the other - 3 cm.

Iron fixation occurs in two stages:

- fixing the bend at the ridge;

- fastening of the entire strip.

To fix the sheets, clamps are used, which are fixed to the bars of the roof sheathing.

Profiled sheets are attached to the crate on the roof with the help of special nails with rubber seals, which ensure the water tightness of the joints. The arrangement of roofing materials with a polymer coating does not require additional coating during the years of operation.

But, if you use ordinary steel, then it is subject to priming and painting. Processing should be carried out immediately after completion of roofing work. It is better to paint twice.

Mounting Features

When working with roofing iron, some points have subtleties that require explanation. Now we will point to them so that you can understand how to cover the roof with iron correctly.

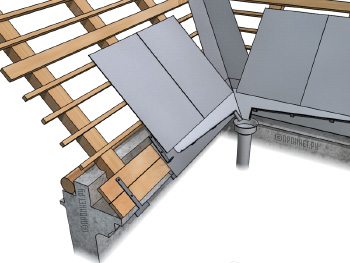

Many roofs contain complex sections, such as a chimney. What if you need to work with them?

Initially, you need to measure all the parameters roofs. Ordinary or profiled iron sheets according to geometric parameters are prepared in the workshop. It is necessary that in difficult places water does not flow under the roof.

To do this, you need to make a collar, the shape of which depends on the pipe. As a connection in such places, you can use standing and inclined locks (folds) for sheet steel or additional elements for profile roofs.

At first glance, a metal roof is not difficult, but if you are not confident in your skills, invite experienced builders to do this work.

Did the article help you?