The main task of the roofing material is to protect other building structures (rafter system, insulation, etc.) from external factors (snow, wind, rain, sun, dirt). Roofing tin perfectly copes with this task, and its service life is not small. If you want to cover the roof of your house with this material, read the article.

The main task of the roofing material is to protect other building structures (rafter system, insulation, etc.) from external factors (snow, wind, rain, sun, dirt). Roofing tin perfectly copes with this task, and its service life is not small. If you want to cover the roof of your house with this material, read the article.

What is a tin roof? This is a roof covered with sheet steel with a thickness of 0.5-1 mm, installation is carried out using a seam connection (edge bending).

There are two types of gesture:

- Zinc coated (galvanized steel). Service life 25-30 years.

- Uncoated (black steel). Service life 20-25 years.

I would like to point out right away that this type of roof it is more expensive than a coating made of soft materials (flexible roofing, rolled roofing).In addition, you will need constant care (cleaning, painting), and it is better to entrust the installation to specialists.

Despite this, this material is in demand. In addition, it also has advantages:

- Ease;

- Incombustibility;

- Versatility (used for roofs of varying complexity);

- Waterproof;

- Durability.

But if your metal roofing has small volumes, and its configuration is not very complicated, you can try to do all the work yourself.

Sheet preparation

Work begins with the preparation of sheets (pictures). For this you will need the following items:

- Rags;

- Hot drying oil;

- Workbench with a metal corner nailed to the edge;

- roofing pliers;

- Kromkogib (for the future);

- mallet;

- Roofing hammers;

- Ruler;

- Scriber.

Sheets are wiped from dirt, grease, dust, rust. Then two layers of hot drying oil are applied on both sides. After that, paintings are made from the sheets.

Advice! Grease from sheets can be easily removed with a rag soaked in gasoline. It is desirable to add a dye to the drying oil. This will help you easily notice the gaps on the tin when it is applied.

Pictures are an element of roofing, the edges of which are prepared for seam connection. Usually, two sheets of iron are used to make one picture (the exception is long sheets of 1.5-2 m).

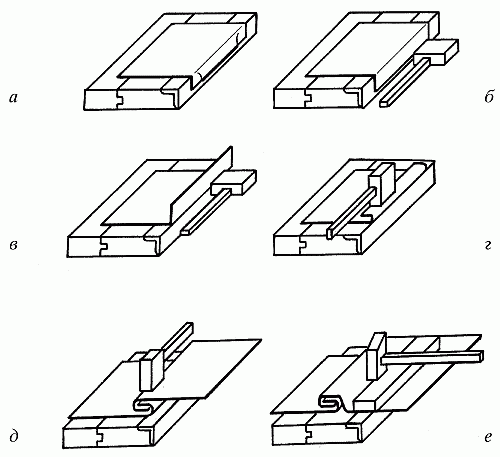

Between themselves they are fastened with a single recumbent seam connection. This is done as follows: the edges of the top sheet are bent by 10mm, the bottom by 5mm (Fig. 2 a, b) at a right angle. Next, we bend the edges to the plane of the main sheet (Fig. 2d).

Galvanized roofing sheets we connect it into a lock (Fig. 2 e) and seal it with a mallet. The last action is cutting the fold. To do this, you need a wooden plank and a hammer.We lay the bar along the fold and tap it with a hammer (Fig. 2 e).

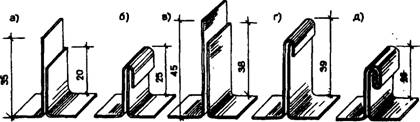

The edges of the picture are folded as follows: on the right side by 35-50 mm, on the left side by 20-25 mm. This will be a standing seam connection (see Fig. 3). We bend the upper and lower ends, as indicated above, for a single lying seam connection.

The next stage of preparation is the manufacture of clamps. These are steel strips for attaching paintings to the crate. They are cut from the same sheets of metal from which the paintings are made. The strips should be 20-25mm wide and 120-130mm long.

Installation of paintings

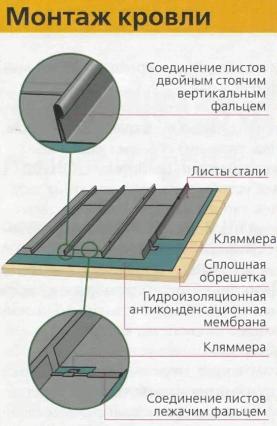

Now you can proceed to the installation of the crate. . It is made from a 50x50 mm edged board. It is stuffed perpendicular to the rafters, with a step of 250 mm.

If the distance is greater, the metal may sag, and this is not desirable.

Advice! If a solid crate is used, it is imperative to leave a ventilation gap between it and the iron sheets.

Pictures are attached from left to right. When laying the first row, an overlap is made: along the gable overhang - 20-30 mm, along the eaves overhang - 100 mm. As mentioned above, paintings are attached to the crate with the help of clamps.

They are bent by 20-30 mm and attached to the boards with nails, on the right side of the sheet. Then they are bent along a standing fold. The distance between the clamps is 60-70 mm.

The installation of the roof is carried out in vertical strips from the ridge to the overhangs. Between themselves they are connected by recumbent folds. For this, it is most convenient to use a metal strip 50 mm wide, 800 mm long and 5 mm thick.

Lying folds should go strictly horizontally, relative to the ridge of the roof.In this case, it is recommended to coat them with putty (sealant) when flattening.

The second row of pictures is mounted as follows: the pictures are attached to the first row. It turns out that the edge of the second row will be smaller in size than the first.

The strips are fastened with standing folds, their finished height should be 20-25 mm. In this case, it is desirable to shift the recumbent folds by 15-20 mm horizontally, relative to each other.

This will facilitate the installation of standing seams. For bending, you can use special pliers or hammers, as you like. All ridges should be the same height, well compacted.

Docking on the ridge is made when all rows of pictures are mounted. Excess tin is cut with special scissors along the ridge, on one side below, on the other above, so that a standing fold can be formed. Then the edges are bent.

For your information: all metal elements of the roof (clasps, nails, bolts) must be made of the same material, the same as the coating. Otherwise, the life of the roof will be determined by the life of this element.

A tin roof will last a long time if all the nuances are taken into account during installation. Therefore, we will dwell on the most common mistakes when constructing a tin roof.

Mounting errors:

- If the roof pitch is less than 14C, the crate should be made continuous.

- Water can seep through the connections. To avoid this, use a vertical connector with tabs. When crimping the seam, it is advisable to use silicone sealant (lubricate the joints), this will increase its water resistance. When using sheets of tin with a length of more than 10 m, fastening to the crate is carried out using floating clamps.

- When installing metal ceilings, the use of screws and bolts should be excluded. Rigid fastening does not give freedom of movement, which leads to deformation of the coating.

- With all responsibility, it is necessary to approach the arrangement of ventilation. If condensation collects on the back of the roofing, it will lead to corrosion and premature failure of the material. To avoid this, roofing felt or roofing material is placed directly under the coating. The entire roofing pie is arranged in such a way as to ensure good ventilation of the under-roof space and minimize the influx of warm air from inside the house. For this, special barriers and vapor barriers are used. The attachment points are carefully checked, as they usually leak warm air.

- Under the influence of temperatures, expansion or contraction of the metal can occur. To avoid deformations, special connecting elements should be used that are designed for such changes.

- When designing, all loads should be correctly calculated, first of all, this applies to regions in which there is a lot of precipitation, especially in winter.

- When installing metal aprons around shafts and at junctions with vertical surfaces, it should be borne in mind that their installation by tightly pressing against a vertical surface does not provide a proper connection, water will still get under the metal. To avoid this, these elements are installed in niches or strobes. And this applies not only to metal roofs, but also to other materials (rolled, flexible). Traditional junction installation schemes are shown in Fig.5.

This is with regard to the installation of roofing from sheets of metal. But besides this, on almost any roof there is a need to use tin. These can be drainage systems, metal aprons around ventilation shafts, ridges, junctions, etc.

Roofing tin work is not always difficult, but a crucial step in the installation of any roof. Therefore, if you are not confident in your abilities, invite specialists.

Did the article help you?