Modern metal roofing can be mounted from sheet and rolled steel or non-ferrous metals - aluminum, copper, zinc, titanium. The durability of such a coating is 30/100 years. Manufacturers produce three main types of metal roofing materials.

Modern metal roofing can be mounted from sheet and rolled steel or non-ferrous metals - aluminum, copper, zinc, titanium. The durability of such a coating is 30/100 years. Manufacturers produce three main types of metal roofing materials.

Smooth sheets

Roofing iron appeared in the 19th century and has since become the main type of sheet roof finishes.

Steel can be covered with a thin protective layer of zinc or not have it (black iron). A simple steel roof will last you 20/25 years, a galvanized counterpart - up to 30 years.

Desirable roof pitch from smooth sheets of metal should be 14/22 °.Galvanized steel is produced, usually as sheets, with dimensions of 2.5×1.25 m and a thickness of 0.5/1.5 mm.

Metal roofing made of iron has a number of advantages:

- Light weight (4.5/7 kg/m²), which makes it possible to use light supporting structures for the roof;

- the ability to equip the roof of any of the complex forms;

- a flat surface provides an unhindered runoff of atmospheric moisture;

- fire resistance;

- ease of repair;

- relative cheapness.

Roofing zinc is produced as an alloy with a low content (0.1/0.2%) of copper and titanium. These components give zinc the necessary plasticity.

The largest manufacturer of this roofing material is Union Zinc. It produces sheets with dimensions up to 5×0.66m, as well as rolls with a width of 0.2/0.66m. Coating thickness -0.2/1mm.

Zinc metal roofing can be equipped with a slope of at least 5º and only on a solid base flooring. The service life of such a coating is more than 100 years.

Copper is considered an elite roofing material, tk. costs several times more than iron and zinc.

Advantages copper roof – architectural expressiveness, high resistance to corrosion, durability (more than 100 years), environmental friendliness and no operating costs. The main disadvantage is the increased deposition of condensate on the inner surfaces of the coating, which is explained by the high thermal conductivity of this metal. .

This type of metal roof at first it has a natural color, but then darkens to a dark brown hue.

After a few years, the copper becomes covered with a noble patina and already has a bluish-gray tone. Such metal roofing is sold as rolls having a width of 0.6 / 0.7 m and a thickness of 0.6 / 0.8 mm.

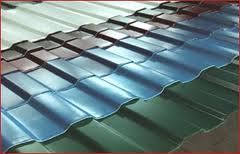

Profiled metal coating

Such sheets are produced mainly from galvanized or having an external polymer layer, steel, as well as aluminum.

Note! The wave (profile) on such materials can have different depths and, in addition to imparting additional rigidity to them, also simplifies the joining of sheets, and also gives them a decorative effect. Installation of corrugated board is carried out on the crate, on top of a waterproofing layer made of roofing material or its analogues.

Aluminum metal roofing has not been widely used until recently. However, the situation has changed and it is gradually gaining popularity. This material is produced in the form of sheets, the width of which is 1/2 m, and the thickness is 0.6/0.8 mm.

Aluminum has a number of advantages: low weight, ease of installation, complete resistance to corrosion and service life of more than 75 years.

Metal tile is the most popular in domestic construction

Metal tiles are profiled sheets made of steel, copper, aluminum, which imitate the shape of natural ceramic tiles.

For this purpose, large-sized metal sheets, coated on both sides with anti-corrosion primer, are stamped in the form of a separate section of a tile roof.

Such metal roofing, on the front side, is covered with polymer-based paint, mineral pigments and fillers, which imitates the color of ceramic tiles.

Metal tiles are produced in various types, which differ in configuration, profile height, sheet width, color and finishing layer coating.

Important! Metal tiles are recommended for roofs with a slope of at least 14°. When arranging insulated roofs coated with this material, it is necessary to make a ventilated space or lay a layer of vapor barrier.

Sheets of metal tiles are laid on the crate, which has a step of 35/50 cm.

Tiled metal roofing has an extremely low weight (4/6 kg/m² for iron and 1.5 kg/m² for aluminum), excellent decorative effect and durability - about 50 years.

Did the article help you?