Copper roofing, at the moment, is the most reliable and durable. Although copper is considered a non-ferrous metal, this roofing material is quite affordable. Yes, it is certainly more expensive than other roof coverings, but its characteristics are much higher.

Copper roofing, at the moment, is the most reliable and durable. Although copper is considered a non-ferrous metal, this roofing material is quite affordable. Yes, it is certainly more expensive than other roof coverings, but its characteristics are much higher.

Copper roofing is timeless. In Russia and Europe, you can still find buildings that are architectural monuments with copper roofs.

Many of them were built in the 18th and 19th centuries, there are some that are already about 700 years old, but they still attract attention with their splendor and noble beauty of copper.

Currently, copper roofing is experiencing a rebirth. More and more people prefer roofs made of this metal. Modern technologies allow not only fast and high-quality installation, but also turn the roof into a real architectural masterpiece.

By design, copper roofing is divided into three types:

- Copper tiles.

- Copper bowl.

- Fake roof.

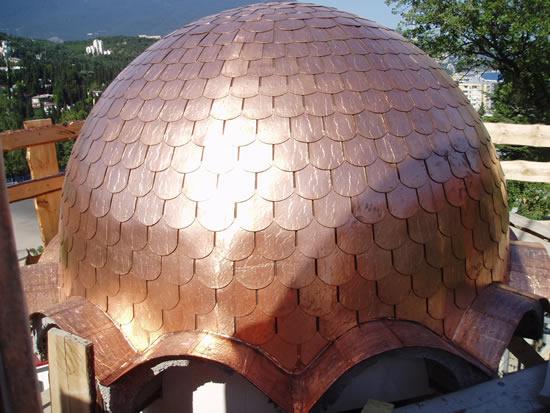

The copper tile is piece material. From individual sheets of copper, fragments are made that look like traditional tiles. In finished form, such a roof can resemble an imitation of various surfaces: stone, wood or scales.

This type of roofing is very often used to cover turrets and domes. The tiles are laid in two layers. The top layer covers the joints of the bottom ones. In this way, the tightness of the coating and protection against leaks are created.

Copper checker - special plates in the form of a rhombus, square or trapezoid. For their manufacture, a copper sheet for roofing up to 0.8 mm thick is used, from which the desired shape is cut.

The upper and lower parts of the checker contain locks: direct and reverse. The installation of adjacent plates consists in a reliable connection of parts and a special riveting. I would like to note that most of the work is done manually, due to this, such coverage is considered time-consuming and expensive.

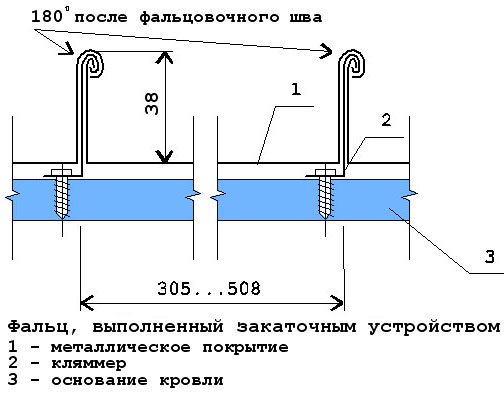

Seam roofing: the technology itself consists of roofing elements (paintings). They are made of rolled copper up to 0.8 mm thick. The paintings are interconnected by horizontal and vertical seams using a special seaming machine. Sheets are fastened with clamps, which are located under the surface of the sheet.

The cheapest of all types of copper coatings is copper shingles. This is a copper shingle. The plasticity of copper and the flexibility of bituminous tiles are perfectly combined, creating a beautiful and reliable roofing. This type of material is available in various thicknesses and shapes.

For your information: seam roofs are considered the most reliable in terms of sealing. This is due to the fact that there are no holes in the coating sheets.

According to the appearance of the coatings, copper roofing is divided into:

- Classic. Imitates traditional tiles. At first, the roof has a natural copper color (bright, golden-red). After 7 years, the color changes to bronze-brown. And after 25 years, the copper roof will be covered with a patina of malachite-green hues.

- Patinated. Malachite-green copper sheets are used. This color is maintained throughout the lifetime of the roof.

- oxidized. Even before installation, copper for roofing goes through a process of natural oxidation and acquires a red-brown color. And so it remains.

Roofing copper - copper produced by modern industry. Usually copper sheets are made, from which roof coverings are made in the future.

But not all of them are the same. Some of them have pronounced external effects. For example: tinned copper.

It has a matte gray tin coating that does not change throughout the life of the roof. Or lacquered copper roofing.

A protective polyurethane layer is applied on top of the copper plates, which gives the material a light shade. But regardless of the color of the roof, the characteristics of the material remain the same. We invite you to consider them.

Characteristics of a copper roof

Scientists have long established that copper has a beneficial effect on the human body.It helps fight diseases and infections, stabilizes the functioning of the nervous and immune systems, internal organs (liver, heart), and stops the aging process.

Of course, all this does not apply to the technical characteristics of copper, but as additional, positive aspects when choosing a roof, they can also play a role.

- The most important characteristic of a roof is its service life. In copper, it is from 100 years and above. As mentioned earlier, some are already 700 years old. . And this fact speaks for itself.

- Corrosion resistance. Over time, roofing copper, under the influence of external factors, is covered with a malachite-green film, patina. It naturally seals the surface. Due to this, the anti-corrosion properties of the roof and its wear resistance are increased.

- The ductility of the metal ensures the lightness and flexibility of the copper roof. This material perfectly passes all tests for bending and strength, and also complies with GOST and TU. Fragments of a copper roof have a weight of 5.3 kg/m2.

- Fire safety. This material does not burn, withstands temperatures up to 150 degrees.

- Frost resistance. This factor depends on the thermal conductivity of the metal, which allows you to organize natural heating of the roof and does not allow ice to form. And so copper is able to withstand frosts down to -70.

- Ease of maintenance. Copper roofing does not require special care, painting and maintenance, which significantly reduces maintenance costs and does not require additional efforts.

- Environmental friendliness. Copper for roofing is a natural material that does not emit harmful substances into the atmosphere, is harmless to the human body and the environment.

- This roofing roofing material can be used to cover the roofs of any structures. This does not require reinforcement of the truss structure.

- Aesthetics. A roof made of copper has a special color and richness of natural shades. Due to the durability of the roof and the aesthetic appearance, this type of roof has become prestigious.

For your information: the initial price of a copper roof is much more expensive than other types of roofing materials, but if you take into account further maintenance and service life, you get a completely different picture. So the choice is yours.

Understood the characteristics. Now consider how the installation of a copper roof is made.

Copper roof installation

You will have to mount the roof in several stages:

- Roof truss system.

- Roof ventilation.

- Laying the crate.

- Laying sealing materials.

- Copper roofing.

- Roof connection and installation of junction points.

Now let's look at everything in order

The device of the truss system. The frame is recommended to be made of logs and timber of coniferous wood. Before starting work, all wooden materials are treated with an antiseptic and fire retardant solution. The ideal option is to dip them for a while in this solution, but this is not always possible.

Therefore, a sprayer or brush should be used. During the construction of the truss system, loads are calculated in accordance with the rules and regulations of SNiP 2.01.07-85.

Roof ventilation. This stage is very important in the construction of any roof. The ventilation device for copper roofs is made in a special way. For warm roof holes are made that provide inflow and outflow of air in the under-roof space.

The inlet (air inlet) is made on the eaves, the lowest point of the roof, the outlet (outflow) - in the ridge, the upper point of the roof. On such roofs, the insulation must be protected by a layer of vapor barrier.

For cold roofs, a base is installed above the ventilated attic, which is laid on the rafters. After that, the intermediate layer is mounted, and then the copper coating is already laid.

Crate. For these purposes, you can use waterproof plywood, beams or edged boards. The crate is mounted solid, without gaps. All wood products must be treated with protective solutions before laying.

Laying sealing materials. For this, lining roll materials are used.

Laying is done parallel to the ridge, starting from the bottom. The overlap between rows should be at least 8 cm. The material is nailed to the battens with roofing nails, with a step of 12 cm.

Copper roofing. For this, the folding method is used. But first, the copper roof is laid out along the slopes of the roofs, and after that it is connected by the method of a double, standing seam.

Connection and installation of roof units. Between themselves, the paintings are connected with the help of folds. In finished form, it has a height of at least 2.3 cm. Copper clamps are used to fasten the plates to the base.

On the main surfaces, it is recommended to use 4 pcs/m2, in increments of 40 cm, along the perimeter the quantity increases to 5 pcs / m2, with a step of 35 cm. The device of cornices, ridges, junctions and valleys is made taking into account all technical calculations. Also, all joints must be sealed.

Copper roofing is a reliable and durable roofing, but in order for the roof to serve for a long time and not leak, all rules and regulations should be strictly observed when laying.

To perform the work, it is better to invite experienced specialists, since the material is expensive, and it is better to study on cheaper roofs.

Did the article help you?