Roof load-bearing structures are one of the most complex building systems. They consist of many elements interconnected in some cases in a rather complex way. And, since the rafters form the basis of this frame, the connection of the rafters is the most important node in the roofing device. In what cases is such an adjunction necessary, with the help of what details, and how it is performed - this article will tell.

Roof load-bearing structures are one of the most complex building systems. They consist of many elements interconnected in some cases in a rather complex way. And, since the rafters form the basis of this frame, the connection of the rafters is the most important node in the roofing device. In what cases is such an adjunction necessary, with the help of what details, and how it is performed - this article will tell.

rafters are connected to other roof elements in several cases.

This can be a constructive interface with other details, or - building up the rafters themselves.

Connection nodes can be grouped as follows:

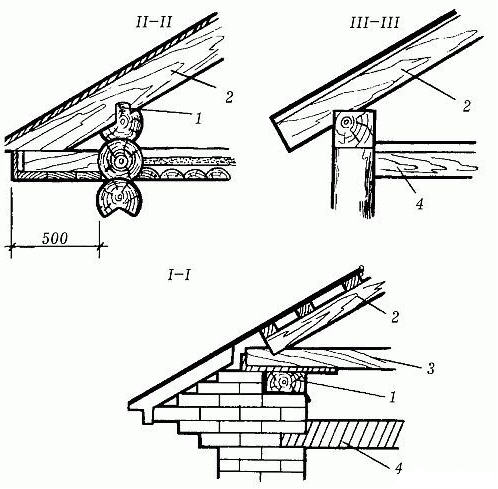

- Attachment of rafters to wall structures

- Connections of elements inside the truss frame

- Rafter leg extension

Rafter systems are divided into layered and hanging. But in each of these systems, the rafters must transfer the loads from the roof to the supporting structures - walls or columns, provided for by the building project.

Therefore, the methods of connecting the rafters in the roof structure with the supporting contour of the building can be considered the most important in the construction of the roof.

With rare exceptions, regardless of the rafter system, the project provides for a Mauerlat - a rafter beam. In the case of layered rafters, it will work in shear, in the case of hanging rafters, in compression, in the direction that matches the orientation of the load-bearing walls.

But, in both cases, it is necessary to connect the supporting structure of the roof with the box of the house.

Despite the apparent similarity, the joints of the layered and hanging rafters are arranged differently.

This is due to physics - the vectors of the acting forces have different directions in the first and second cases, therefore, the fasteners must also compensate for different types of loads. The strength of the system as a whole will depend on how to connect the rafters.

For sloped roofs, an urgent problem is to prevent the rafters from slipping along the Mauerlat (rafter). Here, the main load from the weight of the roof and the precipitation lying on it acts perpendicular to the floor plane.

Accordingly, the connection with the Mauerlat should prevent the "spreading" of the rafter legs, especially if the length of the rafters is large. For this, various combinations of carpentry joints such as "tooth" and "thorn" are used, as well as nails, bolts, metal overhead parts.

In the case when the shrinkage of the building box (especially the wooden box) is expected, sliding fasteners are used to allow the roof structure to repeat the deformation of the building

The plank is attached to the rafter leg, and the corner is attached to the rafter.

The bent edge of the corner creates a constant engagement between the structural elements, at the same time - does not interfere with the movement of the leg within the free travel of the bar.

At the end of the shrinkage, all legs will take some final position, and the displacements will stop.

The position of the corner can be fixed, for example, with a wedge, or you can leave everything as it is. This is a good example of how to align the rafters in a newly built building.

Important information! The sliding connection is used only for the layered construction of the rafters. With hanging rafters, with the exception of cases when a floor beam is used as a screed, the structure itself allows the roof to not depend on the deformations of the building.

Since the metal parts of the rafter connection are able to provide both sufficient strength and some plasticity at the same time, such products are widely used in roofing equipment - these can be corners of various shapes, plates or planks.

In a hanging system, the rafters are fastened in several ways, depending on the specific design. Fastening also depends on the specific node, the nature of the loads on it.

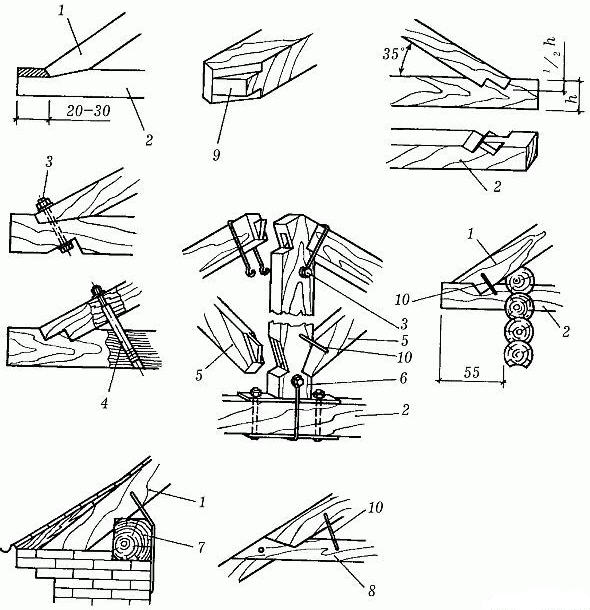

Those structural units that work in compression, as a rule, are connected using a tooth (double for heavy loads), or a spike.

For reliability, the assembly can be strengthened with bolts, brackets, or metal overhead parts.Plates and corners are fastened with screws and self-tapping screws, holes are drilled for bolted connections in the parts to be joined, with a diameter of 1 mm less than the bolt section.

Staples are usually hammered into the side surfaces of wooden parts. In all these cases, the dimensions of the fastener are determined by the thickness of the rafter.

Clamps are used in those nodes where parts work in tension / rupture. They cover the supporting part (for example, a puff or a ridge beam), and are bolted to the attached one - the same headstock, or strut.

In this case, the clamp can be attached both to the side surface of the part and pass through it, being fixed with nuts.

The upper bundle of rafters is performed:

- cutting them at the same angle, and connecting them with end planes (at the same time, at the appropriate angle, at least one 150 mm nail is hammered into the sidewall of each of the rafters),

- fastening to a ridge beam

- side edges.

Naturally, in the latter case, the rafters must be shifted along the length of the roof by an appropriate distance.

With any of these methods, additional fastening of the connection with metal or wooden plates is possible. The way how to connect the rafters, among other things, dictates the length of the hanging part of the leg.

1-rafter leg

2-puff

3 bolt connection

4-clamp connection

5-strut

6-grandmother

7-mauerlat (rafter beam)

8-crossbar (beam)

9-thorn

10-bracket

It should be no more than 4.5 m, with a larger size, additional runs (support beams) are launched along the slope, parallel to the Mauerlat and the ridge beam.

ADVICE! To ensure the absolute symmetry of all rafters, it makes sense to make a template before installing them - a “model” rafter that has all the necessary cutouts, angles and dimensions. With the help of a construction pencil, it is then quite simple to prepare the required number of parts on the ground, being sure of the accuracy of their dimensions.

We lengthen the legs

Periodically, it becomes necessary to connect the rafters along the length. Most often, this situation develops in the case of a large length of the slope.

After all, as a rule, lumber comes in pieces up to 6 m long.

There are also several extension options available.

- Ends sawn obliquely

- tongue-and-groove connection

- Side faces of boards or beams

- Relying on an intermediate run

The latter method is advisable when all rafters are built up at the same distance from the roof overhang.

In this case, the load on each section of the roof will fall on the junction of the rafters in one place, which can lead to deformation. If an intermediate run is not done, it is worth strengthening the joints of any structure with metal overhead parts.

Existing methods of carpentry knots in combination with modern types of fasteners make it possible to make the connection of rafters reliable and ensure its long-term performance.

Did the article help you?