For the construction of roof frames today, different types of truss systems are used. However, despite their diversity, each of these truss systems is based on general principles that provide the roof with the necessary margin of safety.

For the construction of roof frames today, different types of truss systems are used. However, despite their diversity, each of these truss systems is based on general principles that provide the roof with the necessary margin of safety.

In this article, we will analyze the design features of the most common truss systems, and try to formulate recommendations that will be most useful to you when arranging the roof yourself.

Rafter systems: general information

So, rafter system: What is she? In its most general form, the truss system is a roof frame that rests on the supporting structures of the building and serves as the basis for waterproofing, insulation and roofing materials.

The design and dimensions of the truss system depend on:

- Building dimensions

- Building dimensions

- The selected roofing material (first of all, its specific gravity)

- Roof truss material

- Roof loads relevant for the region (primarily wind and snow loads)

- Personal preferences regarding the shape of the roof

Each of these factors is, of course, important for understanding which types of truss system will be optimal for a particular situation.

Material for the truss system

Wood is the most common material for arranging truss systems today.

Most often, a pine beam 150x150 mm or boards 50x150 mm are used, however, if it is necessary to strengthen the structure, the timber is taken thicker, and the boards are sewn together.

Note! In this case, we are talking, of course, about the construction of private residential buildings. In the construction of apartment buildings or industrial buildings, completely different materials and technologies are used.

Wooden rafters must be processed before installation:

- Antibacterial - it prevents the development of rotting processes if the wood of the rafters is in a humid environment (for example, under the influence of intra-roofing condensate)

- Fire-resistant - this treatment reduces the combustibility of wood.

To date, the question "how to process the rafters?" is in no way critical. There is a wide choice of both antiseptics and antipyretics on the market, as well as preparations for complex wood protection (Senezh, Rogneda, Lovin and others).

It is better to process the wood of the rafters with a brush, since spraying does not provide a sufficient level of impregnation.

As an alternative to wood and to increase the reliability of the construction of the truss system, it is possible to use additional metal elements.

Most often, metal profile racks are installed as supports under ridge runs, which are subjected to maximum loads.

However, in this case, the metal-wood contact area must be protected with insulating materials, otherwise the wood may rot due to waterlogging from condensate on the metal.

An all-metal truss system, which is built by a welded method, is devoid of this drawback, since its metal does not come into contact with wooden parts.

However, metal rafters require a more serious approach to roof insulation, as metal acts as a "cold bridge".

However, regardless of what material the rafters themselves are made of, the rafter system is created in such a way that its design is as rigid as possible.

That is why the main types of roof trusses strive for a triangular shape - after all, as you know, it is the triangle that is the most rigid figure.

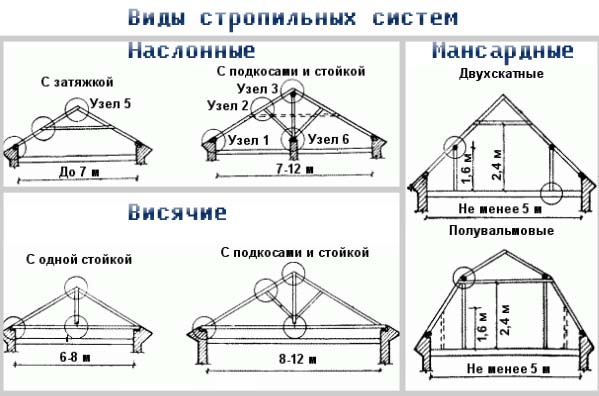

Based on the design features of truss systems, they are distinguished by the following types:

- hanging rafters

- Rafters

Next, we will consider each of them in as much detail as possible.

Hanging truss system

The simplest type of truss systems are hanging rafters. Their features are as follows:

- Do-it-yourself roof rafters hanging type have only two points of support for each pair of rafter legs. Most often, the load-bearing walls of the house act as such support points. Rafter legs in this case work both in compression and in bending.

Note! The rafter legs should not rest on the walls themselves, but on the support beam - Mauerlat. Mauerlat is a thick wooden beam or a structure made of boards sewn together, rigidly fixed to the end of a load-bearing wall. The rafter leg is fastened to the Mauerlat using a notch; in addition, the rafter is fixed with a bracket or bracket.

- In this case, the entire structure of the truss system creates a bursting force, which is transmitted to the wall fence.

- The most common way to compensate for bursting is to arrange a puff that connects each rafter pair in the lower part. Most often, the puff is placed at the very bottom - then it acts simultaneously as a roof overlap. However, the puff can be placed higher - but then it should have more power, because the load on it is greatly increased.

- In addition to compensating for the bursting force, tightening prevents the rafter legs from moving apart.

Rafter system of layered type

Unlike hanging rafters a layered truss system requires the presence of an average load-bearing wall in the building.

The structure of layered rafters is distinguished by the following features:

- The ends of the layered rafters rest on the walls of the house, and the middle part - on the internal load-bearing wall or internal columnar supports.

- The rafter legs of the layered truss system work only for bending, while the compression load is removed from them. As a result, thinner elements can be used to create a layered truss system, and the entire truss system is lighter. At the same time, savings in lumber can be very significant.

- When arranging a roof on a complex building, the types of rafters can alternate. Where there is an average load-bearing wall or support, we install layered rafters, and where there is no support, hanging-type rafters.

hip roof rafters

The hip hipped roof requires the arrangement of a special truss system.

Due to the complex geometry of this roof, its rafters perform different purposes, therefore, there are several types of them:

- Skew (diagonal) rafters - connect the corners of the building with the ends of the ridge beam, and form the edges of the future roof. Sloping rafters are the longest and should be the most durable, since they bear the main load.

- Ordinary (central) rafters - connect the ridge beam with the Mauerlat on the sides of the slopes. Ordinary rafters are installed strictly parallel.

- Corner rafters - sprigs - are shorter than ordinary ones, and connect the Mauerlat not to the ridge, but to the rafters. Together they form the plane of the roof slopes.

As you can see, this system is a bit more complex than traditional hanging or layered rafter systems, but it provides the necessary strength for a roof with four slopes.

Thus, by choosing the right rafter system and using the types of rafters corresponding to the design features, you can independently create a strong and reliable frame for your future roof.

Did the article help you?