The erection of a roof is a very laborious process, but it serves a rather noble purpose - protecting the house from wind, precipitation, and heat loss. When building a house on your own, installing rafters with your own hands, which serve as the basis for the entire roof structure, can become quite feasible with the proper approach to business and compliance with all the rules. In this article, we will describe the design features of the roof truss system, dwell on the rules and nuances of the entire list of works on its arrangement.

The erection of a roof is a very laborious process, but it serves a rather noble purpose - protecting the house from wind, precipitation, and heat loss. When building a house on your own, installing rafters with your own hands, which serve as the basis for the entire roof structure, can become quite feasible with the proper approach to business and compliance with all the rules. In this article, we will describe the design features of the roof truss system, dwell on the rules and nuances of the entire list of works on its arrangement.

What you need to know about the design of the roof and the truss system in particular

Before you install the truss system with your own hands, you need to understand the structural features of the roof structure.

The roofs of houses, as a rule, make up inclined planes called slopes. The basis of the roofing slopes is precisely the rafter system in combination with the crate laid on it under the roofing.

The lower ends of the rafter legs usually rest on the Mauerlat. At the intersection of the slopes, horizontal and inclined ribs are formed.

The horizontal edge is called a ridge, and at the intersections of the slopes that form the incoming corners, grooves and valleys are created.

The edges of the roof, protruding above the walls of buildings, are called eaves or gable overhangs. They are located horizontally with a ledge beyond the contours of the outer walls.

After the rafters and battens are laid, an outer covering material, called a roof, is arranged above them. Before its installation, steam, heat and waterproofing is mandatory.

Depending on the slope angle of the roof slopes, the roofs are divided into pitched (with a slope of more than 10%) and flat (with a slope of 2.5% to 10%). The roof planes that provide the slope of the water are called slopes.

Roofs of this type have a slope of more than 2.5% and are divided into:

- Shed - having support on two outer walls of different heights.

- Gable - having support on two outer walls of the same height. The end triangular walls that form with this shape are called tongs (when constructed from boards) or gables (when erected from stone). Therefore, the alternative name for such roofs is gable.

- Four-slope or hip - roofs with triangular slopes (the so-called hips) on the end sides. If the hip is not brought to the eaves, then the roof is called half-hip.

- Hipped - roofs, four slopes of which are made in the form of identical triangles converging at a single point.

- Broken (attic) gable - roofs, each of the planes of which is two rectangles that are connected to each other at an obtuse angle.

It is a certain order of installation of rafters on the roof, most often, that forms the type of pitched roofs.

DIY rafters serve as the main load-bearing elements of the roof structure, which are designed to cope not only with the weight of the roof, but also with the pressure of wind and snow.

Therefore, the calculation of the truss system is carried out, guided by the type of roofing material, as well as the usual thickness of the snow cover and wind strength for the area.

To achieve the rigidity of the frame, the rafter legs are fastened to each other, and in order to avoid tearing off the roof by the wind, the frame is securely connected to the “box” of the house.

As a rule, when building private and country houses, wooden truss systems are applicable, which are quite simple to manufacture and at the same time are easy to process and install.

Features and types of rafters

Roof trusses are flat lattice structures that serve to cover large premises.

They are represented by a geometrically unchanging system of rods, which are located in a single plane and connected to each other at the ends.

Truss rods, which are placed on the upper contour, are called the upper belt and, accordingly, according to the lower - the lower belt. Vertical internal rods are usually called uprights, while inclined ones are called braces.

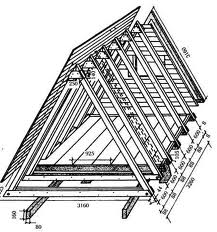

The installation of rafters implies, at the core of its system, the presence of such a figure as a triangle, since it provides the greatest rigidity.

The main element of the truss truss is the actual rafter legs, which are installed far away from the slopes and serve as support for the crate.

There are the following types of rafters:

- hanging rafters;

- layered.

The method of installation of rafters and their type is chosen depending on the slope of the roof, the load from wind and snow, and the roofing used.

Consider how to install hanging type rafters. The peculiarity of hanging rafters is that they rely only on two extreme supports, for example, on the walls of a house without using intermediate supports.

Hanging rafter legs perform bending and compression work. In addition, this design creates a significant bursting horizontal force transmitted to the walls.

It is possible to reduce the indicator of this effort by means of puffs (wooden or metal) connecting the rafter legs.

They can be placed both at the base of the rafters (in this case, the screed simultaneously serves as a floor beam - this option is most often used in the construction of attic roofs), as well as above.

Moreover, the higher it is placed, the more powerful and reliable it is supposed to be, as well as to connect with the rafters. Installation of this type of truss system is applicable in cases where roof spans are from 7 to 12 m and additional supports are not provided.

Unlike layered rafters, they create only vertical pressure on the Mauerlat. The main elements of hanging rafters are the tightening of the lower belt in combination with rafter legs.

Now let's look at how to build layered rafters.

Layered rafters are to be installed in houses equipped with an additional load-bearing wall or intermediate columnar supports located in the center relative to the side (external) load-bearing walls.

The ends of the layered rafters rest on the side walls, while their middle part is supported in the form of an inner wall or load-bearing pillars. As a result, their elements work like beams - only in bending.

Installation of a single roofing system over several spans may involve the installation of layered and hanging roof trusses with their alternation.

In places where there are no intermediate supports, hanging rafters are used, and where they are, layered ones. If the distance between the supports (roof span) is more than 6.5 m, and if there is an additional support element - 10-12 m - layered rafters are used.

The layered truss structure is equipped in the same way as in buildings with a frame system. The crate is made of planks of sparse or beams of double solid flooring and is attached to the rafters with nails. .

Under the flooring of a soft roof made of roofing felt or roofing material, the crate is made in the form of a continuous flooring, consisting of two plank layers (the so-called double flooring).

The bottom layer of the crate is called working, the top - protective.Sparse (having a gap of 20-30 mm) or solid single flooring is used as a base for a coating of flat asbestos-cement slabs.

A crate made of beams with a section of 50 * 50 mm is applicable as a base for corrugated asbestos-cement sheets (classic slate), tiles and fiberglass corrugated sheets.

Before you assemble the rafters, you need to understand the methods of their fastening. Depending on the type of material from which the structure is built, the rafter legs will be attached in one of the following ways:

- connection with the upper rims of wooden block-beamed and chopped buildings;

- connection with the upper strapping of wooden frame buildings;

- connection with supporting bars of stone buildings. In this case, the thickness of the mauerlat should vary between 150-160 mm, while it itself can be selected partial (the bars of which are laid only at the junctions with the rafter legs) or solid (the bar is laid along the entire length of the building).

When selecting rafter legs of a small section, in order to protect them from sagging, a lattice of struts, racks and crossbars is used. Struts and racks are made of logs with a diameter of at least 130-140 mm.

During installation, the rafter leg is cut into a puff.

To exclude the possibility of the end of the rafter leg sliding along the tightening and chipping off, it is necessary to insert the rafters with a tooth with a height of 1/3 of the tightening height, with a spike, or using two methods at the same time.

Advice! The puff can remain intact and will not be chipped if the rafters are mounted approximately 30-40 cm from its edge. The rafter leg is cut into the end of the puff, while moving the tooth as far as possible.

Rafter Installation Instructions

The technology for installing rafters is approximately as follows:

- Roof structure elements are made of lumber of 1-2 grades without wormholes and rot.

- Bars and boards are cut to the desired size along the length using a circular saw for transverse cutting, and on the same machine, the products are trimmed according to a given profile (template). They are sawn in width on a circular saw for longitudinal cutting. Before assembling, the rafters are debarked and marked according to templates.

- The assembly of elements of the truss system is carried out on the striker in templates. The parts to be assembled are placed at the striker in a convenient order for ease of use without additional effort and movement.

- On the striker, before starting the assembly of the truss structure, it is necessary to apply with the help of coal or chalk a diagram of the rafters to be assembled in natural size. Also, on the striker site, you can fill the strips that will fix the exact location of the assembled rafter legs, in other words, apply a template under the laying of the rafters.

- Upon completion of the cutting, as well as the control assembly, the truss elements are subject to marking and complete packaging. Large-span rafter legs need to be tested so that they can be assembled during construction without adjustment.

- In the truss elements, nests are selected for installing dowels and bolts.

Advice! Rafters with a small span can be assembled at special enterprises and delivered to the construction site already assembled.

Truss structures made of logs

In the manufacture of rafters from logs, round barked wood 18 cm in diameter is used.Logs are selected even and straight, without curvature, wormholes and rot. Minor irregularities are subject to processing with an ax along the cord.

The puffs, through which the rafter legs are connected, are made of the best quality wood. First of all, a log is selected for puffing and it is trimmed to the required size in length.

Due to the fact that roundwood is supplied with a maximum length of 6.5 m, for large spans, the tightening is usually made using 2-3 logs fastened together along the length. Next, logs are selected for the manufacture of rafter legs. Racks and struts, which are shorter, are made from scraps or from the shortest logs. The ends of the selected logs are hewn and marked according to a template, which is made of thin sheet metal or plywood.

The points of the cuts, upon completion of the marking, are cut out and cleaned with a sharply sharpened ax. Composite-type beams on lamellar dowels are used in the arrangement of floors, as well as the shape of the upper truss belts. The beams are rallied from bars on wooden dowels. Perhaps the most common prefabricated section structure is a beam, which is a structure of two or three coniferous wood beams, which are interconnected by lamellar pins made using hardwood (mainly oak, sometimes birch). In beams, the pins are set along the length, excluding only the middle part, in which the shear forces are relatively small.

Beams are made from beams of the first grade, dried to a moisture content of not more than 20%. As for the moisture content of lamellar pins for making beams, it should be no more than 10%.

The beams are assembled by means of a special device, which consists of two supports (stands), on which a shaft is located that performs rotation in two bushings.

On each side of the shaft on the trestle bars are placed. The beams are shifted at the ends with the help of clamps-strands.

Advice! To achieve the required mounting lift in the beams, two spacers are attached to the shaft, having a thickness corresponding to the lift.

Due to the fact that the ends of the beams are coupled, and their middle is bent under the action of the spacers, the beams become bent according to the magnitude of the lift.

In the process of bending the beams, it is necessary to ensure that the planes of the beams that are in contact with each other are precisely fitted to each other.

And you should observe the construction rise. Further, according to the template, the places for mounting the dowels are outlined and the nests are selected. After that, lamellar dowels are inserted into the nests.

After performing these operations, on one of the sides, the trestles are pulled out from under the device and the shaft is turned simultaneously with the beams by 180 degrees, then the trestles are put in place, the nests are selected again and the dowels are inserted into them from the second side of the beams.

Upon completion of the installation of the dowels, the strands must be removed, from which the finished beams straighten a little, while slightly reducing the building lift, and the dowels must be tightly pinched in the sockets.

At the end of the rafter system and the fastening of the lathing, the next step in the process of erecting the roof is the roofing and roofing pie.

Did the article help you?