When long rafters are needed for the construction of the roof, but they are not available, then it is necessary to splice the rafters along the length. The beam for the manufacture of rafters, like the rafters themselves, have standard sizes. The larger the cross-sectional area of the rafters, the greater their length.

To achieve the required ratio between the length and thickness of the rafter legs, it is possible to increase the thickness of the rafters by attaching additional elements (rafter boards, beams). In this article we will talk about the methods and design features of splicing rafters in roof truss system.

How to lengthen the rafters is an important issue in the construction of the roof.In order to increase the length of the rafter legs, it is often necessary to connect short structural elements to each other (timber, rafter boards, etc.).

How to lengthen the rafters is an important issue in the construction of the roof.In order to increase the length of the rafter legs, it is often necessary to connect short structural elements to each other (timber, rafter boards, etc.).

Flexural rigidity in places where the rafters are joined is extremely rare, usually plastic hinges are obtained there. To solve this problem, the joint is made in the place where the bending moment is practically zero.

When installing a plastic hinge, its distance from the support for the rafters is taken as 15 percent of the installation step of the rafters (span length) on which the connection is located.

Due to the fact that the length of the spans between such elements as the Mauerlat and the intermediate support for the rafters, as well as between the intermediate and ridge supports, is completely different, when joining the rafters, an equal-strength, and not equal-strength and equal-bending scheme is used, as when joining runs.

It is much more important to create the same strength of the rafter along the entire length than to create an equal deflection. A completely different situation occurs in the ridge run. There, the primary task is to ensure an equal deflection: then the roof ridge will remain at the same height.

During the construction of hip roofs, rafters are used that are directed to the corners of the walls (internal or external). Such rafter legs are called rafters. They are longer than usual and are a support for the shortened rafters of the slopes.

The rafter system is assembled, most often, from individual wooden elements - rafters, boards, timber, logs.

Consider the following methods of splicing rafters:

- Splicing rafters by butt jointing.For an ideal connection of two rafters, it is necessary to cut off the joined ends of the rafters at an angle of ninety degrees (to prevent deflection of the junction of the two elements of the rafter, the cut of the end of each of the elements must be maintained at ninety degrees). Connecting the cut ends hanging rafters, it is necessary to fix the connection using a metal fastener or an overlay from the board. To cover the junction of the rafters on both sides, overlays from the board are used, each of which is nailed with metal nails through one, in a checkerboard pattern.

- Building rafters in the way of an oblique cut. The method got its name "oblique cut" due to the fact that the adjoining ends of the rafters are cut at an angle of 45 degrees, after which the cut ends are joined together and fastened in the middle with a bolt, the diameter of which is usually 12 or 14 mm.

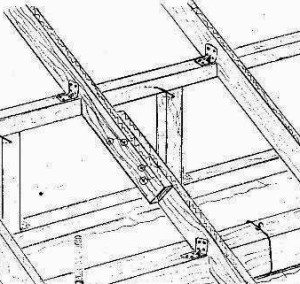

- The connection of the rafters with an overlap. With this method, the rafters are extended as follows: the wooden structural elements are superimposed on each other with an overlap of one meter or more, so that in this case it is not necessary to observe the accuracy of cutting the ends of the rafters. Further, as in installation of rafters butt jointing method, punching with nails is carried out along the entire length of contact of the connected elements in a checkerboard pattern. Sometimes, instead of nails, studs are used, which are fixed on both sides with nuts and washers.

Important: Please note that the installation of the connected beams in the building system takes place in such a way that the load affects the joints as little as possible.

Pairing rafters

Conjugation is the connection of parts, in which the parts partially or completely enter into each other. In our case, the details are the wooden elements of the roof.

Rafters are connected to beams or mauerlat using a tie-in, or a tooth with a spike, forming rafter nodes.

The upper part of the rafter leg is placed on the ridge run with full or partial connection with the opposite rafter leg.

The rafter structure, which was assembled from boards, is considered no less durable than that which was made using poles and wooden beams.

Boards are built up or connected in a certain order and in some cases their use is much more profitable than using heavy timber, both from an economic point of view and in terms of versatility.

A rafter board is especially often used in the construction of a roof with a cold attic without insulation and its further restructuring into an attic.

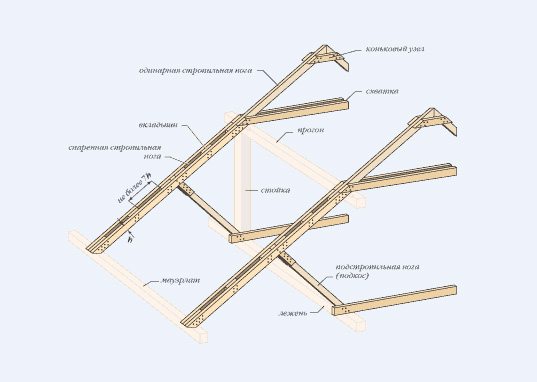

Sometimes, to increase the length of the rafters, rafters are used, which are connected by two boards with a clearance.

The peculiarity of this design is that it is enough to fix single rafters in the upper part of the rafter system, and paired rafters in the upper part, which will be moved apart along the thickness of the upper rafter.

Finding the most rational cross-sectional areas, this combination of rafters significantly saves building material and facilitates the assembly of the construction of the rafter connecting nodes with each other and the grapple crossbar. Inserts from scraps of rafter legs are inserted between the rafters so that the distance between them is not more than seven heights of the connected boards.

Under such conditions, the flexibility of the rafter paired between the liners is zero, and the rafter leg works as an integral element. The length of the liners should be equal to two board heights or more.

There are two types of rafters from boards: paired and composite.

Twin rafters

Paired rafters consist of at least two boards, which are folded to each other without gaps close to the wide side and stitched with nails through one in a checkerboard pattern along the entire length.

When extending the rafters from paired boards, the parts are joined end-to-end and overlapped simultaneously to the second paired rafter board, which maintains the strength of the rafter and increases its length.

Important: when selecting rafters, it is necessary to ensure that the distances between the joints of the bonded boards of the connection are more than one meter and are staggered along the rafters, which is why each joint is protected by a solid board, and the articulated joints are not opposite each other.

Rafter rafters are the longest elements of truss systems, and twin rafter board is the ideal material for their construction.

Composite rafters

To create a composite rafter, two wooden boards of the same length are placed on the edge and connected through the third piece (liner) to each other. Further, all three boards are nailed in two rows with nails. The length of the liner should be more than twice the height of the board.

The step of installing the rafters between the liners should be less than the value of the thickness of the boards to be joined, multiplied by seven. The first liner is installed at the beginning of the rafters, then the rafter leg will have a thickness of three boards.

The upper part of the rafters is made from one board, which, like an insert, is fastened with nails between the side boards and laid on a ridge beam.

Composite rafters are never used as diagonal rafters.

Did the article help you?