I used to think that waterproofing with liquid rubber is a complex and time-consuming process. But, when I got acquainted with the technology and tried to do the work myself, I was convinced that everything is very simple. Even an inexperienced master can handle waterproofing, the main thing is to have the necessary equipment at hand and follow simple recommendations.

How to organize work

Let's figure out what aspects the workflow consists of and what is needed for high-quality work. I will talk about the process using the example of a concrete roof, but in the same way, waterproofing material is applied to the floor, basement and other structures. The technology is always the same.

Materials and tools

From the materials you need the following:

To apply liquid rubber, you need the following:

- Liquid rubber coating plant. This is a special equipment that is used only for these purposes. It’s not worth buying a fixture, it’s better to rent it, so you will save a lot of money, because surface coating equipment costs around 150,000 rubles;

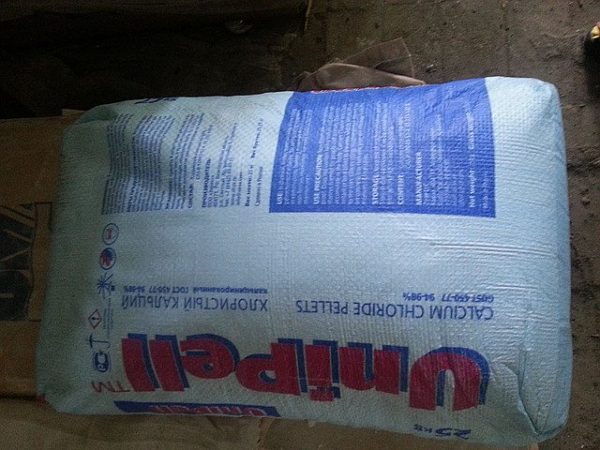

- Sprayer for applying the composition. A special version with two nozzles is used. From one, an emulsion of liquid rubber is supplied, from the second - an aqueous solution of calcium chloride, which acts as a catalyst and ensures the strength and moisture resistance of the applied composition;

- Brush brush or roller. Used for applying primer at the stage of surface preparation. Instead, you can use a sprayer with one nozzle, in which case the work will go much faster;

- Glasses and respirator. You can't work without these protections. When sprayed into the air, a cloud of fine dust is formed, which, getting into the respiratory tract and eyes, can cause irritation, and in difficult cases, poisoning. The simplest options are also suitable, the main thing is that they are available;

- Painter protective suit. It is not necessary to use this protective equipment, but keep in mind that your clothes will become unusable after work. Particles of liquid rubber will constantly settle on it, which then cannot be washed off. Therefore, if you want to protect your clothes, buy a suit, its price is about 200 rubles.

Work must be done on a dry, clean surface. Therefore, before starting, be sure to clean the base. If roofing is being done, then pick up a warm period without precipitation in the coming days.

The working process

Waterproofing the roof with liquid rubber is carried out in the following order:

| Illustration | Stage description |

| The surface is thoroughly cleaned of debris. It is best to first walk with a whisk and remove the main dirt, and then vacuum the base again. If you don't have a vacuum cleaner, you can dampen the broom and use it to pick up the dust.

|

| Soil is applied to the base. Here it is important to evenly distribute the composition over the surface in order to strengthen it and close all the pores that are always present in concrete. Apply primer liberally, but do not leave excess on the surface. If you have a surface covered with a rolled roof, then it is not necessary to prime it. Just clear out the trash. |

| The surface must dry. This usually takes about a day. In no case do not start work if there are wet areas on the base.

Roofing rubber will not fall on them and you will have to redo the work afterwards. |

| Equipment for applying liquid rubber is connected. With the installation, there is always an instruction with a photo, according to which anyone can understand all the nuances of the connection.

The hoses are inserted into a container with liquid rubber and into a container with a solution of calcium chloride. If the length of the hoses allows, then everything you need can be placed on the ground or indoors by stretching the hoses through the window. Most often, the installation operates on a 380 volt network, decide in advance where and how you will connect the equipment. |

| The tape is attached to the junction. In our case, we painted vertical surfaces paint, so the tape was glued directly onto the fresh coating layer. The better you seal the joint, the less likely it is to leak.

As practice shows, in 80% of cases problems arise precisely at the joints and junctions. |

| Painted parapets must dry. It is best to paint the surface on one day, and on the second to start work. Do not use oil paints, they take a long time to dry. It is better to use modern nitro enamels or alkyd-based compounds. |

| Joints are processed first. Liquid waterproofing of the roof is first of all applied to all junctions, carefully go along the perimeter, distributing the composition by 10 cm on both sides of the joint.

Apply liquid rubber liberally to fill in any unevenness and cover the junction of the tape with the concrete surface. |

| Hold the sprayer at a slight angle to the base. The distance to the surface should be 30-40 cm. You need to drive in stripes left and right, capturing about one and a half meters at a time.

It is important to control the quality of application, the mixture should completely cover the surface, but there should be no smudges on it. |

| The first layer is applied over the entire surface. Liquid rubber for roofing provides maximum protection against moisture only when applied in two layers.

It is best to apply one layer at a time, so as not to treat individual areas later. This ensures the best adhesion. |

| The second layer is applied. Ours will be white. In this case, no preparatory measures are necessary before spraying liquid rubber.

The exception is cases when a lot of time has passed between the first and second application and dust has settled on the surface.

|

| The finished surface is left to dry.. You can walk on it the very next day. If you do not damage the surface, then it will last for decades. If you are wondering why the first layer is gray and the second is white, then everything is simple: the white composition is more expensive and there is no point in using it for the first layer, because apart from colors there are no other differences. In the future, you can update the coating by simply applying a new layer. |

Conclusion

Using this review as an instruction, you can easily process a roof, plinth or other structure with liquid rubber yourself. The video in this article will help you understand the topic even better, and if you have any questions, ask in the comments below.

Did the article help you?