To perform a high-quality repair of a metal roof, you need to have professional skills.

To perform a high-quality repair of a metal roof, you need to have professional skills.

The repair itself is carried out in several stages:

- external inspection of the roof both from the outside and from the inside. It is necessary to check all the rafter junctions in the system, since, first of all, deformations appear in it, which are caused by shrinkage or cracking of the wood, as well as loosening of the fastening;

- when the wood begins to rot, it should be cut off. And in more serious cases, when the cross-section of racks, rafters and some other elements of the roof has decreased, then they need to be strengthened or replaced;

- if all elements of the supporting structures are made of wood, then after repair or replacement they should be thoroughly impregnated with an antiseptic.But before carrying out work, all elements must be installed in the position as provided for in the project in order to ensure a flat surface;

- it is necessary to carry out a correction in the cornice covering of all places that have burst, as well as align the overhang lines and attachment points;

- small holes must be cleaned of dirt, paint, rust, and then patched with steel or sealed with universal sealant, and joints and folds where leakage has occurred should be sealed with two-component hermabutyl;

- patches after applying to the roof must be painted. If the roof is all painted with high quality, then the patches should only be touched up so that they do not stand out on the roof. In addition, roof repairs are carried out from the bottom of the slope upwards.

How to repair a roof

Repair of a metal roof should be carried out only by qualified specialists, since it is necessary to take into account the roof structure, the angle of inclination, the location of the drains and many other important factors.

If the repair technology is violated, then leaks and subsequent repairs cannot be avoided.

For repairs, a variety of materials are used:

- non-ferrous metals;

- sheet or rolled steel;

- metal tile.

Repair of a roof made of galvanized steel consists of eliminating leaks and mechanical damage. These roofs are of two types: corrugated roofing and seam roofing.

When the installation of the roof was carried out with a single seam, leakage often occurs due to mechanical damage.

Repair of a steel roof consists in identification and elimination of defects. If the patch is not installed professionally, it often results in a complete roof replacement.

metal roof

Metal roofing is considered the lightest in weight. The operation of such a roof is very expensive, but it is beneficial to use it in the construction of private houses.

Roofs of all types and levels of complexity are covered with iron, and the main costs relate only to periodic painting.

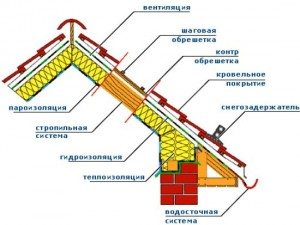

The device of a metal roof consists of lathing bars with a section of 5x5 cm, along the ridge, and boards are laid on the slopes of the cornices. Boards should be laid in steps of at least 25 cm, since the lathing with this type of roofing should not be continuous.

If you do not follow this rule, then the inside will not be well ventilated, which will soon lead to corrosion and shorten the service life.

Tip! The material for installation is prepared below, and then lifted up the roof. Sheets of roofing steel are cut on the ground, and folds, corners should also be bent and paintings should be prepared. Then the paintings are rallied to each other in strips only with short sides - 2 or 3 pieces each, when the slope is long.

The roofing is produced as follows: the paintings are joined into strips with the help of lying folds.

When the roof is roof pitch 16 degrees, then use single folds, and if less, then double. The folds should be located across the roof slope - they should be parallel to the ridge so as not to interfere with the flow of water from the roof.

Standing folds are joined together by strips that can be located across the roof slope, they also will not interfere with the flow of water from the roof.

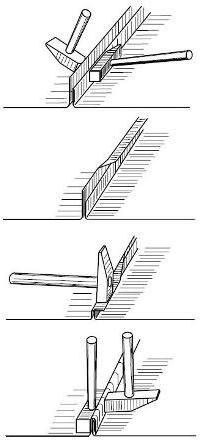

On the roof, iron sheets are fixed with the help of clamps, which are made from roofing steel. Clamps are installed in ordinary strips, and two fasteners are enough for one sheet.

To fix the sheets of material, the flat lower end is nailed to the crate, and the one that is folded in half is inserted between the sheets and embedded in the crest of the standing fold.

Roofing works using galvanized steel are carried out in the following order:

- cover cornice plumb lines and install wall gutters;

- lay roofing;

- install water pipes.

On the cornice board, “crutches” are first stuffed, and the cornice overhang is covered with strips of sheet steel. Then the upper edges of the strips are nailed to the crate with nails.

Next, wall gutters are laid with a slope to the drainage tray and fixed with the help of hooks of the picture of the gutters.

Next, carry out the installation of roofing material. They lay out the strips of paintings in rows - they cover the plane of the slope with them, and in the process the clamps are stuffed. Then, as 5 paintings are laid out, they are rallied together with standing folds.

A standing large fold is bent along the roof ridge in the case when the planes of the slopes are completely covered by the roofing. To do this, bends are made from the ends of the upper paintings: on the one hand -3 cm, and on the other 6 cm.

This work is very difficult, and a small mistake in the calculation and cutting of pictures often leads to skewed rows. In the device of a metal roof, downpipes and other roofing elements are installed last.

Roof installation

Installation of a metal roof is the most important and necessary step in the construction of buildings.

In order for the roof to be reliable and serve for a long time, you should follow the basic rules:

- Design a roofing project

- Accurately measure the area

- Choose quality materials

- Do the right roofing.

Today, the variety of roofing is simply amazing.

The most popular roofing materials are:

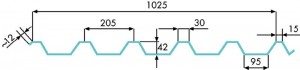

- metal tile roof;

- folded;

- slate;

- soft;

- copper;

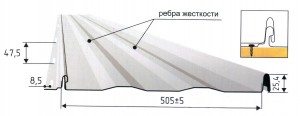

- corrugated board;

- aluminum.

The appearance of metal tiles pushed back a little seam roof: technology which is considered the most reliable today. This coating is characterized by the fact that all elements are connected using folds.

In the manufacture of sheets, traditional materials are used: copper and galvanized steel with a polymer coating.

Clamps are used for fastening. In addition, sheets can have different connections: single, double, recumbent, standing.

To your attention! Installation of a metal roof is carried out manually, using a special tool or a modern zip-machine. When installing a roof, the following work is performed:

- dismantling of the old coating;

- processing of the supporting structure;

- installation of roofing material;

- repair of gutters;

- restore thermal insulation.

Such a roofing will last a very long time and retain its appearance at the same time.

Galvanized roofing steel

On both sides, the material is covered with a layer of zinc, which protects it from corrosion.

For roofing, cold-rolled hot-dip galvanized steel is used.

The thickness of the roofing steel is 250-320 g/m².Very often, steel with a thickness of 0.5 mm is used for roofing.

On the Russian market, you can find metal tiles made of 0.4 mm steel, and during the installation process it must be handled very carefully. For roof elements, steel with a thickness of 0.6 mm is used.

This material has traditionally been and remains the most common for roofing in Russia. Galvanized steel allows you to arrange roofs of any complexity.

In addition, sheets of material are used for the construction of grooves, cornice overhangs, valleys, ridges, gutters and wall gutters.

Did the article help you?