Are you interested in the technology of laying metal tiles on the roof? I will talk in detail about the specifics of the installation work, be sure to list the safety rules and give examples of common mistakes. Following the suggested instructions, you can do this work yourself.

- Tools and materials

- Installation work in detail

- Stage 1: Preparatory work

- Stage 2: Installation of waterproofing

- Stage 3: Installation of the crate

- Stage 4: Installation of valley elements

- Stage 5: Mounting the adjoining elements

- Stage 6: Installation of the eaves strip

- Stage 7: Laying and fastening of metal tiles

- Safety rules for working with metal roofing

- Common Mistakes

- Conclusion

Tools and materials

You will need:

- Manual electric saw with carbide teeth;

- cutting scissors;

- Lever scissors (for ease of use, they are available in right, left and straight versions);

- Forceps with 40° bend;

- Hammer;

- mallet;

- Construction stapler and staples;

- Scissors for cutting vapor barrier film;

- Screwdriver with nozzles for the head of the self-tapping screw;

- Measuring tool and marker;

- Soft brush for sweeping away sawdust that will appear when cutting metal tiles;

- Enamel, matched to the color of the sheet, in case of scratches in the protective coating.

Working at height requires the use of insurance. The simplest option is a strong rope thrown over the skate: on the one hand, the rope is attached below, and on the other hand, the rope is tied around the belt. If there is a special safety belt and professional insurance, use them.

From the materials you will need:

- Metal tiles with standard dimensions (width - 1180 mm, sheet length - 3000 mm, thickness 0.50 mm);

- additional elements;

- Vapor barrier membrane;

- Vapor barrier tape for gluing joints;

- Wooden block 50 × 50 mm;

- Construction nails (length 100 mm);

- Board 50×100 mm;

- Board 32×100 mm.

Installation work in detail

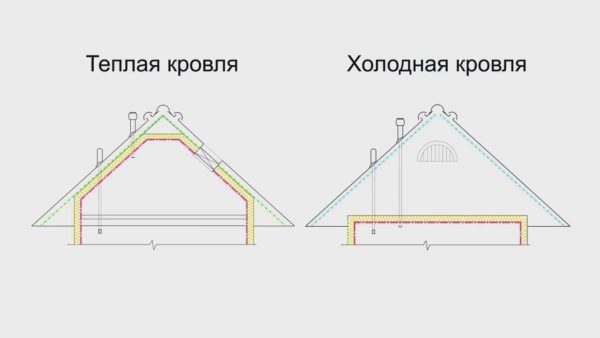

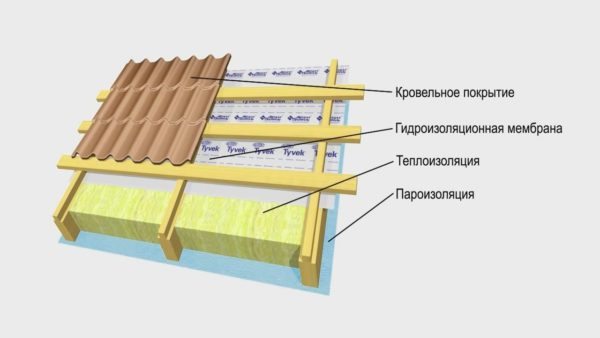

On the diagram you can see two options for the installation of roofing systems. In a warm roof, thermal insulation is mounted directly in the gaps between the rafter legs.In a cold roof, thermal insulation is laid on the ceiling. In the instructions below, we will consider how to lay tiles on a warm roof.

Installation instructions for metal tiles consist of the following steps:

- Preparatory work;

- Installation of waterproofing;

- Installation of the crate;

- Installation of valley elements;

- Installation of adjoining elements;

- Installation of a cornice strip;

- Installation of metal tiles.

Let's consider the above steps in more detail.

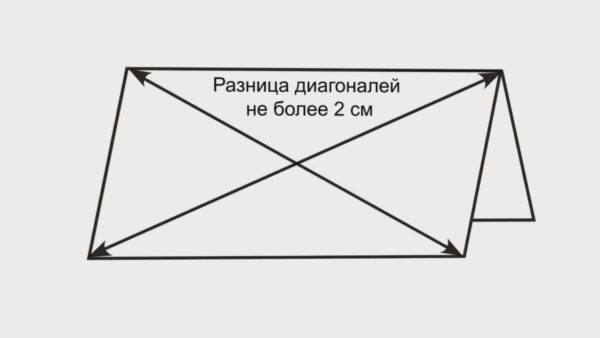

Stage 1: Preparatory work

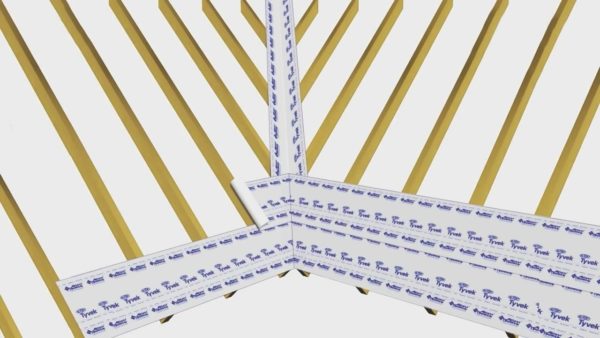

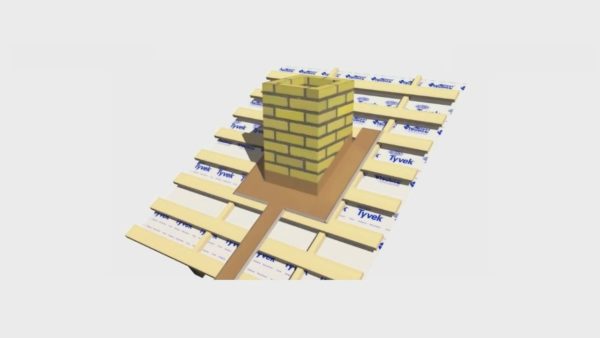

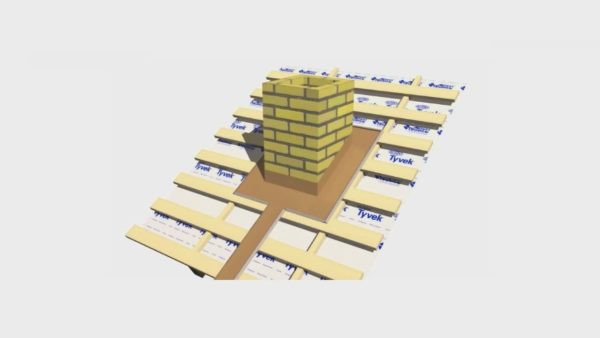

Stage 2: Installation of waterproofing

Stage 3: Installation of the crate

| Illustration | Process description |

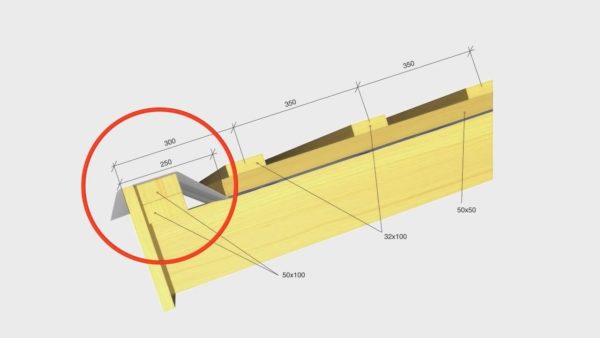

| Fixing the membrane to the edge of the eaves. Along the cornice overhang, as shown in the diagram, we nail two boards 50 × 100 mm one on top of the other and bring the edge to their surface membranes. |

| Crate stuffing. To maintain the same distance between the boards, use a homemade template, such as a board cut. On previously filled bars, we fill a crate of boards 32 × 100 mm in increments of no more than 30 cm. |

| Completion of the installation of the crate. On the ridge we fill one additional board of the crate on each side of the slope. |

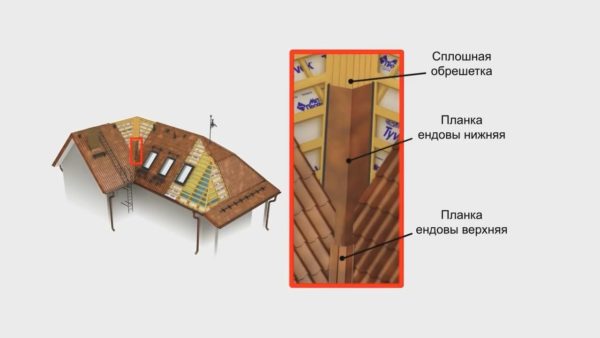

Stage 4: Installation of valley elements

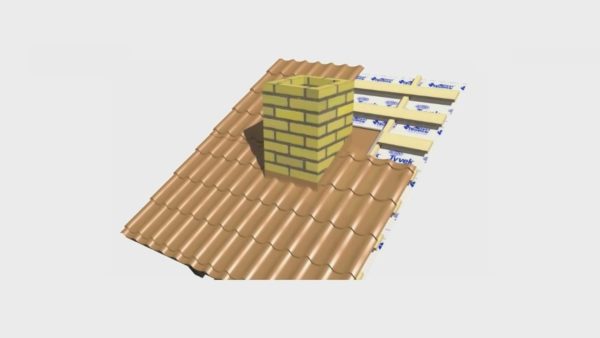

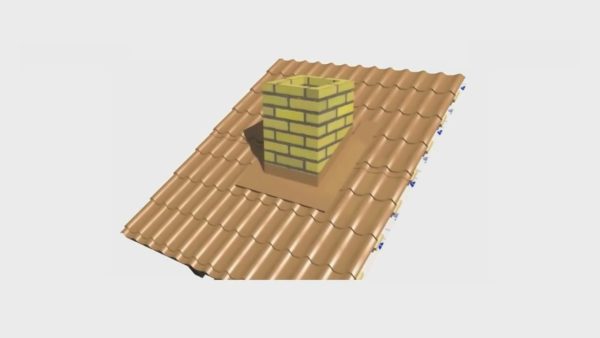

Stage 5: Mounting the adjoining elements

The instruction for mounting the adjoining elements consists of the following steps:

How to properly install the junction bars so that there are no leaks?

Stage 6: Installation of the eaves strip

Stage 7: Laying and fastening of metal tiles

The installation instructions for metal tiles on a roof slope are as follows:

We examined the technology of mounting a solid sheet, which reaches from the ridge to the eaves.

But there are situations when not a single sheet is used, but its individual pieces. In this case, one row is attached first, and the next row is laid out on top of it with an overlap of 15 cm.

Safety rules for working with metal roofing

Common Mistakes

- Fastening snow retainers with self-tapping screws for metal tiles.

This is a very common mistake that leads to the failure of snow retainers under the load of snow mass. The set of most snow retainers includes up to 10 special M8 × 50 self-tapping screws per section.

Do not use self-tapping screws with a smaller diameter, which are used for mounting tiles.

If roofing materials are installed by invited installers, do not be too lazy to check their work, since snow retainers are fixed with roofing screws, because you are too lazy to change the nozzle on a screwdriver.

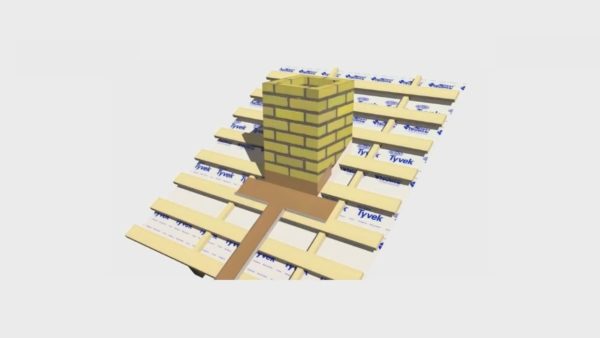

- Gaps at the junction of the roofing material to the chimney.

Another common mistake that subsequently leads to moisture getting inside the roofing cake is the gaps at the junction of the chimney and tiles.

Remember that when performing a pipe bypass, the wall profile and sealant must be at the same level as the outer splash. In addition, the outer apron should adjoin the surface as closely as possible. chimney.

If the installation is not done correctly, as in this photo, the use of bituminous tape is just a temporary solution. Such sealants, due to the temperature difference, will sooner or later leave, and a gap will appear.

- Gaps at the junction of the roofing material to the valley.

The situation is similar to the gaps at the junction, when large gaps are not explained by anything other than the carelessness of the installers. Remember that any open gap is the path through which rainfall is guaranteed to get inside the roofing pie and this will significantly reduce the resource of the entire structure.

If invited specialists are engaged in laying the roofing material, be sure to check the quality of the work, since the considered defect is not uncommon.

- Corrosion of metal along the cut line.

One of the most common mistakes is cutting metal tiles with a grinder with a cutting disc for metal. The mistake is typical for novice installers who do not understand why buy a special cutting tool if there is a grinder.

Cutting metal with a disk rotating at high speed leads to overheating of the paintwork or polymer coating, which protects the tin sheet from corrosion. As a result, the sheet along the cut line will rust, and the coating will gradually peel off.

- Curvature of the sheet due to improper storage.

If the roofing material is purchased ahead of time and stored incorrectly in stacks, the sheet may be warped. As a result, there will be difficulties with laying metal tiles, and you will have to spend time leveling the material or spend money on buying new sheets.

To prevent the sheets of material from deforming, the height of the stack in which they are folded should not exceed 70 cm. In addition, if storage lasts more than a month, the stack must be disassembled and the sheets should be put in the reverse order.

- Overtightened or undertightened screws.

This error is typical for novice installers who do not have sufficient experience.

If you do not tighten the screw, water will enter the hole and the process of corrosion will begin. If the screw is overtightened, the protective coating will also be damaged and corrosion cannot be avoided in this area.

Conclusion

Now you know how a metal roof is mounted. Still have questions and need detailed explanations? Ask about what is interesting or unclear in the comments - I guarantee answers and comments. By the way, do not forget to watch the video in this article, I'm sure it will be interesting to you.

Did the article help you?