At the stage when the house is almost built, the foundation is ready and the walls are erected, you can proceed with the installation of the roof. This video will help you: do-it-yourself roof. You will be able to learn about its device and the process of work at least the most basic. You should start by studying the main types of roofing, the most common in domestic construction.

At the stage when the house is almost built, the foundation is ready and the walls are erected, you can proceed with the installation of the roof. This video will help you: do-it-yourself roof. You will be able to learn about its device and the process of work at least the most basic. You should start by studying the main types of roofing, the most common in domestic construction.

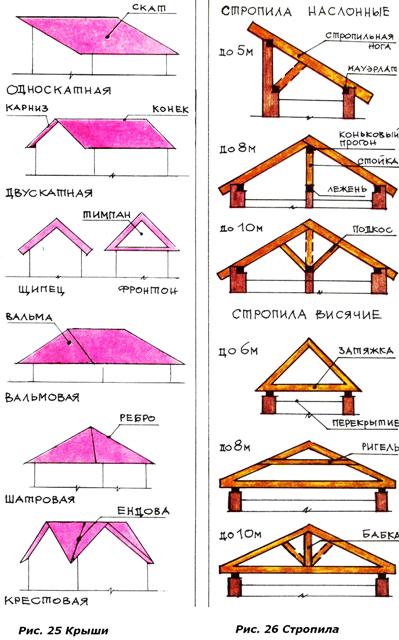

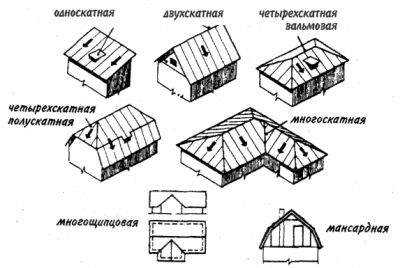

Roof types

There are several basic types of these structures, each of which can be complicated as desired and necessary. If you have planned a do-it-yourself roof at home, first decide on its type.

- Shed.The simplest option, used more often to cover not residential, but utility rooms, as well as baths or outbuildings.

- Dvuhskatnaya. The most common and easily implemented type of roofing, most often found on small houses, cottages and baths. It has only two slopes that join each other at the top.

- Four-pitched hip roof. A little more complicated, but very common and convenient option. It happens hip, semi-hip and tent. The hip type consists of four slopes, two of which are trapezoid-shaped, and the other two are triangles. The semi-hip is slightly different and is a hybrid of a gable in the upper part, and a four-slope in the lower. The tent has four identical slopes in the form of isosceles triangles converging at the top.

- Broken roof. It can have a gable shape with a break in the middle of each slope, or it can be mansard, with bevels on the front sides. Before you make the roof of the house with your own hands, observe what types of roofs most often catch your eye. Quite often, on private houses of average size there are broken mansard roofs. This is not surprising, because in this case it is possible to equip the attic space for living. Yes, and this type of roof is not too difficult to install, reliable, looks attractive, and lasts a long time.

- Multi-gable pitched roof. This is a more complex option, of which there are a great many varieties. Each owner has unlimited scope for imagination, erecting such a roof.

Note! The larger the house, the more complex its layout, the more elements and additions can be on the roof.However, if you do not know at all how to make a complex type of roof, it is best to seek help from specialists. The fact is that the more complex the roof, the more complex the rafter system under it.

Materials you will need

After you have decided exactly on the type of roofing for your home, you should decide on the type of coverage. The fact is that the quantity and strength of the necessary materials for the rafter system will depend on this.

The system should be strongest under the tile covering. Fired clay tile has the largest weight compared to metal and slate. Therefore, before making a roof, resolve the issue with roofing material.

For mounting do-it-yourself roof rafters you will need timber, boards, slats, as well as waterproofing film, insulation, screws and nails. The consumption of materials will directly depend on the size of the house, the complexity of the roof and the nature of the coating.

Calculate everything in advance, even better - if you involve specialists for this.

Sequence of work

When the necessary materials are purchased, you can start building. A power plate must be attached around the perimeter of the top of the walls.

This is a thick bar that serves as a kind of foundation and support for the future system. To make the roof strong with your own hands, make the fastenings reliable from the very beginning, and when laying the Mauerlat, use the level, making sure that there are no distortions.

Anchor bolts are best suited as fasteners. It is advisable to install them when pouring the reinforcing belt, leaving the protruding ends for the timber nozzle.

Before you put a beam on them, you should mark the holes in it, referring to the pitch of the protruding bolts, drill these holes, then carefully put the Mauerlat on the bolts. Use a sledgehammer at the nozzle, making sure that the beam is completely seated in place.

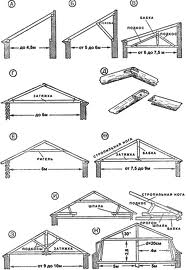

After the Mauerlat is laid, it is time to install the truss truss. For rafters, a thick beam or board is taken.

Keep in mind that the rafters will bear the brunt of the load, so don't skimp on the material. In the future, the rafters will be fastened together with additional elements - jumpers, ties, crossbars and spacers.

If you are already familiar with this kind of installation, and know how to make a roof with your own hands, it will be much easier for you. For those who are doing this for the first time, it is advisable to take an assistant, then the work will go easier and faster.

Note! Each rafter leg at one end should rest against the Mauerlat, and at the other end it should dock at the top with the opposite rafter leg. Calculate the step width of the rafter legs from the size of the roof and the weight of the future coating. The greater the load to be, the smaller the step between the bars should be.

The upper part of the system, where the rafters are joined, is called the ridge. Reinforcing jumpers between the bars are called crossbars. If you are installing a gable-type roof with your own hands, the truss truss will look like a set of triangles fastened together by jumpers.

It is more convenient to make these triangles on the ground, and then mount it by lifting it to the roof.

Installation must be carried out after the ceiling beams are installed. It is most convenient to install rafter triangles by starting with the two extreme ones, fastening them with a ridge beam. Then the rest are installed.

After that, they are finally fastened together with screws and nails. Additional ties and jumpers are placed in the right places, if necessary, to strengthen the strengthening of the system.

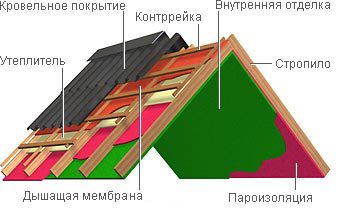

Now, on the rafter legs, along each, slats for the counter-lattice are nailed. It is needed for the gap between the rafters and the crate, for future ventilation of the space between the insulation and the finish coat.

Further, slats are stuffed onto the counter-latches, and a crate is formed. The slats are fixed across the rafters with the required pitch.

If it seems to you that everything is too complicated, we advise you to view the material “do-it-yourself house roof video”, which you will find on our website.

Then you will understand not only the principle and procedure of work, but also make sure that everything is not as complicated as you imagined.

After the entire rafter system is fully completed, the crate is ready, all nodes are securely fixed, you can proceed to the next stage of roof construction.

Protection and insulation

The roof needs protection before it is covered. This is mandatory, otherwise you will not be immune from the cold and regular leaks.

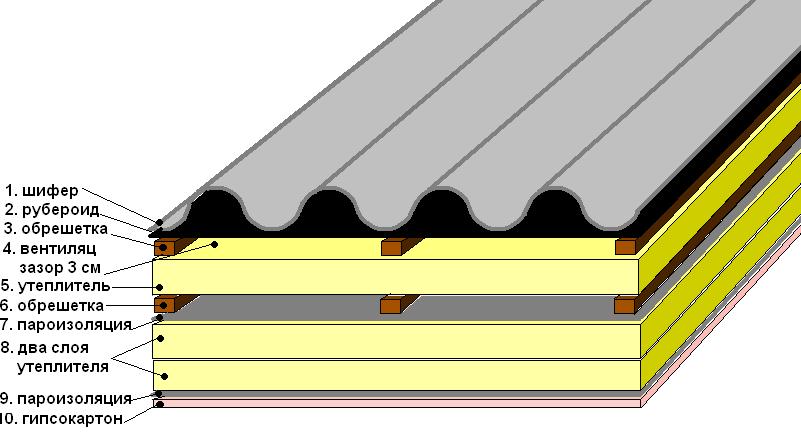

The layers of your roof protection should be in the following order:

- A layer of vapor barrier that protects the insulation;

- Insulation that keeps heat in your home;

- Waterproofing, preventing the penetration of moisture inside;

- Finishing coating from the material of your choice.

It is most convenient to carry out protection work in the following sequence: laying insulation between the rafters is desirable in the first place.

As a heater, special mineral wool is increasingly being used.The material is wear-resistant, durable, light and harmless. You can use foam, but it is undesirable due to its high toxicity and flammability.

To make the roof well insulated, it is advisable to lay the insulation in two layers. You will get a gasket about 10cm thick. Although, for not very cold regions, or in order to save money, you can make a 5-centimeter layer.

Please note - the thermal insulation layer plays another important role - it prevents the penetration of extraneous sounds into your home.

This is especially necessary in places close to roads, railway lines or airports.

After the insulation, you can proceed to the installation of a vapor barrier film. It is pulled from the inside, from the attic, under thermal insulation, attached to the rafter system. It is necessary so that the steam coming from the room does not fall on the insulation layer. Thus, the insulation will always be dry, and its service life will be much longer. It is convenient to attach the film with a stapler to the rafters.

Having wondered how to make a roof yourself, do not ignore the experience and advice of specialists. Try to strictly adhere to the sequence of actions, without missing anything.

Otherwise, you risk at least frequent repairs and the safety of your roof.

Note! After the insulation and vapor barrier are done, you will have to carry out the following stages of work directly from the roof. From above, above a layer of heat-insulating material, a vapor-permeable waterproofing diffusion membrane is laid. Its properties are such that it passes moisture in the form of steam from the inside, but does not pass water that has got in from the outside. That is, if there is even the slightest presence of moisture in the insulation, it will come out.

And it will not allow water to get on the insulation, thanks to the smallest holes in its structure, which release steam and do not let moisture through. We fix it above the insulation, already outside the roof, again, using a stapler.

Now that you've learned most of how to make your own roof, we can say that all preparations for the top coat are ready.

Consider that the so-called roofing pie is ready for you. You have made the protection of your home from water, cold, noise and weather conditions. It's time to cover the roof with the final layer.

Finish coat

Undoubtedly, you have already chosen the material with which your house will be covered. The simplest, inexpensive and functional material is, of course, slate.

However, he loses a lot because of his appearance. The roofs covered with it do not look so respectable and elegant, therefore, it is used more often for the roof of baths, outbuildings, utility rooms, or very small country houses.

If we make a roof with our own hands, using natural tiles, it is necessary to take into account its large weight. With a lot of pluses and good characteristics, the rafter system for this material should be done especially carefully.

After all, the loads that the system will take on will be considerable. The tile is very durable, looks beautiful, you can choose any color of the coating, it is put quickly and easily. However, if your roof is not properly prepared for it, you should not risk your safety.

When the installation of a house roof involves metal roofing, it can be said that you have made a wise decision. Galvanized steel sheets coated with a special composition are not only light in weight.

They are easy to install, are relatively inexpensive, and the coating not only looks great, but also meets all the necessary requirements for wear resistance and safety. Therefore, today most often you can find roofs covered with this particular material.

At first glance, it seems that the roof is lined with individual tiles. However, this is not at all the case, because the material only imitates individual elements.

In fact, these are sheets with a wavy surface that are simply laid in a certain sequence. And, if we make a roof from separate sheets, in the end, it will take on the form of a full-fledged design solution.

Whether it is sheets, or individual fragments, stack them, slipping one under the other. Each material has its own technology, therefore, either strictly follow the instructions, or consult a person who knows a lot about this.

Very often we meet the roofs of houses made with our own hands, which are no different from professional work. Naturally, because each owner does for himself, reliably, for a long time and with high quality.

Of course, it's not worth skimping on materials, but provided you have skillful hands, you can save on some accessories. For example, on the drainage system, which must be done after the roof is covered.

When the assembly of the roof with your own hands is completed, it's time to mount the drain, otherwise your walls and foundation will be flooded with rainwater.

Plastic pipes cut in half lengthwise are perfect for this purpose. And your skills and ingenuity, which all our fellow citizens possess, will help you complete the construction with success.

Did the article help you?