PVC roofing membrane is today a material that is gradually winning its market share from more traditional roofing materials. Studies show that the percentage of roofs equipped with membrane technology is steadily growing, which means that both builders and customers of construction companies appreciate the advantages of membrane roofing.

PVC roofing membrane is today a material that is gradually winning its market share from more traditional roofing materials. Studies show that the percentage of roofs equipped with membrane technology is steadily growing, which means that both builders and customers of construction companies appreciate the advantages of membrane roofing.

Roof membranes: properties and benefits

And yet - why is roofing made of PVC membranes and similar materials so popular? There are several explanations for this:

- Firstly, roofs made using membrane technology are highly durable. The estimated service life indicated by most manufacturers (up to 60 years, subject to the arrangement technology and the absence of mechanical damage) can even be considered somewhat underestimated. Roofing membranes, due to their structure, provide the roof with excellent stability, and thus guarantee durability.

- Secondly, PVC roofing membrane (as well as EPDM and TPO membranes similar in properties) are produced by many manufacturers in the widest range of standard sizes. The length of the membrane coating sheet is up to 60 meters, and the width can be in the range from 0.9 to 15 m. pruning. Consequently, at the end we get a roof with an almost monolithic coating with a minimum of seams and excellent waterproofing characteristics.

- Thirdly, the polymer roofing membrane has high performance. Roofing membranes are practically non-combustible (high fire resistance), retain their properties in a wide temperature range (frost resistance), do not collapse when exposed to ultraviolet radiation, which is very important for roofing material. A significant plus is also the high tensile and puncture resistance, which plays an important role in ensuring the waterproofing characteristics of the membranes.

Additionally, you can highlight the convenience of working with roofing membranes. Light weight (approx. 1.3 kg/m2 membrane coating) with a membrane thickness of 0.8 to 2 mm greatly facilitates the lifting of the material on the object and manipulation with it.

Also, an indisputable advantage is the relatively simple technology for arranging roofing from membrane materials.

If a membrane roof is laid in the building project, a very different membrane can be used.

In addition to traditional PVC membranes, EPDM and TPO membranes are also used today. Next, we will look at all three types with their features, advantages and disadvantages.

PVC membranes

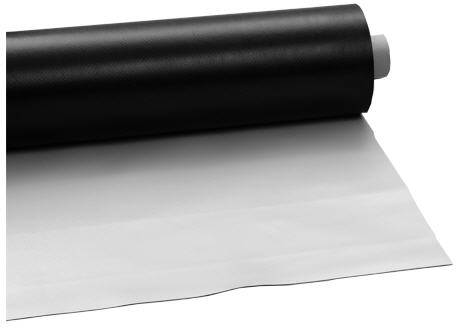

PVC roofing membrane is made from a plasticized polymer - polyvinyl chloride.

To give strength, the PVC roofing membrane is reinforced with a polyester fiber mesh, and to make the membrane more elastic, up to 40% of plasticizers with a high volatility are added to the PVC composition during manufacture.

Thanks to the elasticity, which due to plasticizers, the PVC membrane acquires, the roof becomes more durable and resistant to temperature and other deformations.

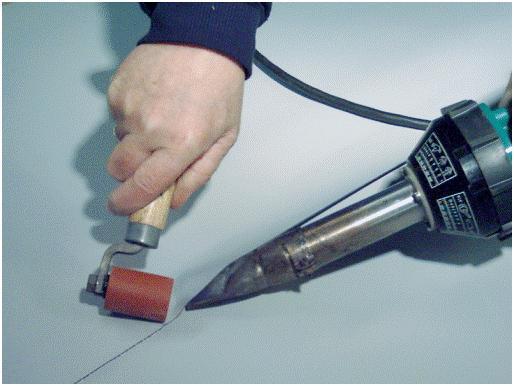

To connect PVC membranes into one roofing sheet, you can use special equipment that welds PVC sheets with a hot air jet.

What are the advantages of PVC membranes over other membrane roofing materials? First of all, these are high indicators of elasticity, resistance to ultraviolet radiation, and also good fire resistance of membranes.

An additional advantage is a fairly wide range of colors (of course, for membrane materials!) - PVC membranes for roofing are made in 9 color options.

The main disadvantage of such membranes is their low resistance to solvents, oils, bitumen-based materials. You should also pay attention to the environmental friendliness with which PVC membranes "do not go smoothly": they contain a large percentage of volatile substances that are gradually released into the external environment.

Among the PVC membrane materials popular on the construction market, one can single out Krovlelon, Alkorplan, Sarnafil, Ogneizol, etc.

EPDM membranes

EPDM membranes are a whole group of membrane roofing materials, the basis for which is a synthetic rubber sheet. Reinforcing the fabric with polyester mesh significantly increases the mechanical characteristics of the membrane, making it more tear-resistant.

The advantages of EPDM-based membranes are low cost, high elasticity, and long service life. Unlike PVC membranes, they are absolutely environmentally friendly and insensitive to bituminous materials.

The main disadvantage of such membranes is the need for an adhesive joint, and as a result, a decrease (in comparison with a welded seam) in the strength at the junction of membrane seals.

The membranes of such foreign manufacturers as Firestone, GenFlex, Trelleborg, as well as domestic brands Epikrom, Elon and others are most in demand on the domestic market.

A separate group consists of composite membranes based on EPDM, which have a multilayer structure.

The top layer of such composite membranes is made from a synthetic rubber sheet, and the bottom layer is made from a polymeric material based on bitumen. Composite EPDM membranes are reinforced with fiberglass mesh.

The advantages that a composite polymeric roofing membrane has are obvious - when gluing an EPDM membrane, molten bitumen can be used as an adhesive layer. The most popular EPDM membranes are manufactured by Foenix.

TPO membranes

TPO roofing membranes are based on thermoplastic olefins. A significant proportion of TPO-based membranes are reinforced with fiberglass, polyester or fiberglass mesh, but unreinforced membranes can also be found.

The advantages of TPO membranes are, first of all, environmental friendliness (the membranes do not contain volatile components), durability, and elasticity at low temperatures. TPO membranes are connected by hot air welding, which significantly increases the strength of the butt welds.

However, in terms of elasticity as such, TPO membranes are inferior to membranes based on EPDM and PVC.

Most often in the retail network you can find membranes Genflex, Sarnafil, etc.

Roofing technology from membrane materials

When the roof is being installed, the PVC membrane acts as a waterproofing material, so additional waterproofing is usually not required.

Usually, do-it-yourself roof installation with the use of membrane materials is produced quite quickly - and this is another argument in favor of their use.

The base for a membrane roof does not require special preparation, except for drying. If a pvc membrane is used for coating, the roof does not even need to remove a layer of old waterproofing.

There are three main ways to install roofing materials on a membrane base:

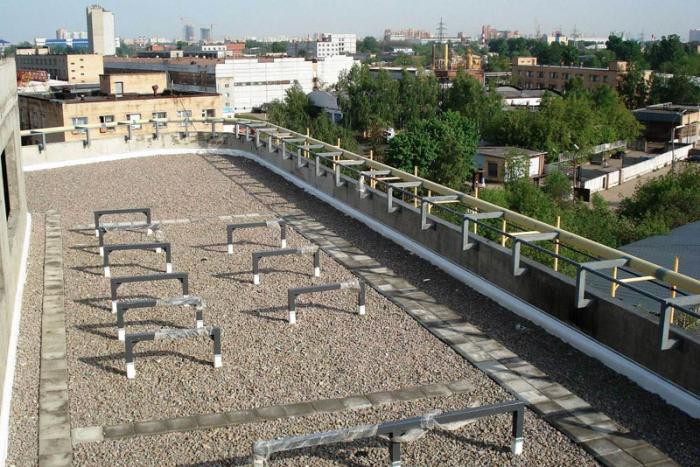

- The ballast method is applicable for roofs with a slope not exceeding 10. When installing membrane roofing material using a ballast method, the membrane is laid freely on the entire surface of the roof, and is fixed only along the perimeter and in places where the membrane adjoins vertical surfaces (ventilation structures, chimneys, parapets, etc.). To hold the membrane sheet on the roof, it is pressed with ballast. The minimum ballast weight is 50 kg/m2 roofs. Pebbles, gravel, concrete blocks, paving slabs can be used as ballast.

Note! When arranging a membrane roof using a ballast method, it is necessary to take into account the bearing capacity of the roof and in no case allow it to be overloaded.

- If a pvc membrane roof is installed on a roof with a large slope, we use mechanical fixing of the membrane. Hot air welding is most often used - this method provides maximum strength of the seams. We weld the longitudinal edges of the canvases with a special welding machine. melting roof membrane material is securely fastened and we get a virtually monolithic roof covering - without stress points where leaks are possible.

- For roofs with complex geometry, we use the adhesive method. Membrane sheet roofing is fastened to the roof base using special double-sided adhesive tapes. However, not all membrane materials can be fixed in this way - and therefore the use, for example, of PVC-based membranes for arranging the roof of roofs of complex shape is limited. To cover such roofs, EPDM membranes or other roofing materials should be used.

Note! Joints between sheets of roofing material, junctions to vertical surfaces and overlaps through the roof ribs should be most qualitatively glued.

Thus, when an epdm or pvc roof is created, the membrane acts as a waterproofing material that prevents leakage.

The properties of membrane materials provide such a roof with reliability, and ease of use only contributes to the growth of their popularity.

Did the article help you?