Translucent plastic roofing is becoming an increasingly common element of modern private homes, city offices and public buildings. The main materials from which it can be made are PVC plates and polycarbonate.

Translucent plastic roofing is becoming an increasingly common element of modern private homes, city offices and public buildings. The main materials from which it can be made are PVC plates and polycarbonate.

PVC sheet roofing

PVC plates have a wavy or trapezoidal profile, the purpose of which is to increase the strength of the structure. Usually they are used for roofing over terraces, verandas or arranging canopies in suburban areas, because. such a roof perfectly protects from wind, snow, rain, but lets in sunlight.

All PVC sheet is produced by extrusion, so it does not contain harmful plasticizers.

The plastic roof turns out to be light and has a density of approximately 1.4 g / cm³.It has good mechanical rigidity and strength, as well as impact resistance.

It can be operated for 3/15 years, depending on the modifying additives. Mechanical qualities and optical properties of such roofing material are reduced by no more than 20%.

Sheets are resistant to ultraviolet radiation and do not let it into the interior of the building. This is because the top layer of PVC roofing contains titanium dioxide, which is an ultraviolet filter.

In addition, plastic roofing has a high chemical resistance: it is insoluble in gasoline and kerosene, alkalis and most acids.

PVC almost does not absorb moisture, does not swell and does not warp under its influence. The undoubted advantage of this plastic is its ability to self-extinguish.

While melting, the material does not form drops. Polyvinyl chloride has heat resistance and can be operated at a temperature of +60/85°.

Note! Among the important advantages of this plastic, as roof coverings - flexibility, low sound, electrical and thermal conductivity. Sheets can be cut, sawn and milled, as well as formed without pre-drying, bent in a cold and heated state, glued and welded.

Sheet PVC cannot be used on roofs with a slope of less than 6%. The overlap of the plates must be at least 20 cm.

You need to cut the material either with a hacksaw for metal, or with a circular electric saw with a carborundum disc. Avoid vibration and pressure at the cutting point. There must be a distance of at least 4 cm from the edges of the sheets to the mounting holes.

Such plastic roofing should not be assembled at temperatures below +5°C.When mounting, fasten the sheets along their upper wave using spacers at the points where the screws are screwed in.

Holes for fasteners should not be punched, but drilled with drills. Their tips should be sharpened at an angle of 60/70 °. To compensate for the thermal expansion of the material, the diameter of the mounting holes must be made larger than the cross section of the screws by 0.5 cm.

As the lesson posted by us shows: “do-it-yourself roofing - video”, the slabs must be laid with a longitudinal overlap, in two waves. Direction - against the prevailing winds, from the bottom up.

Note! The marked side of the plates, on which there is a layer that protects against ultraviolet radiation, must be made front. Do not forget to take care of sufficient ventilation of the under-roof space.

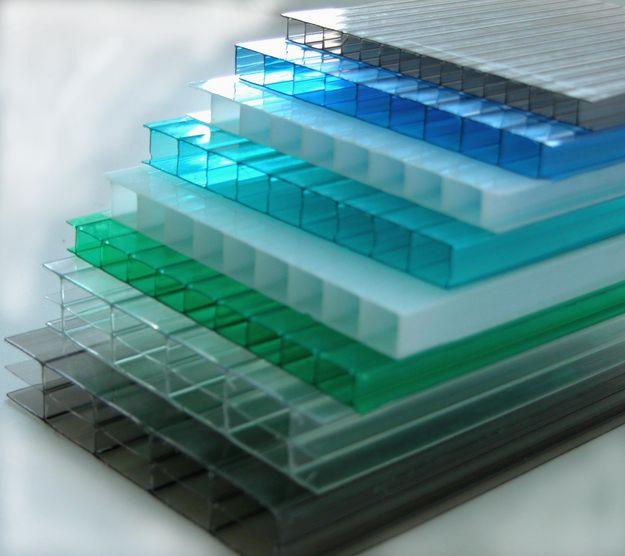

Polycarbonate as a roofing material

Polycarbonate roof is gaining more and more popularity lately, gradually replacing roofing glass. This is explained by ergonomics, low price, high safety and excellent light transmission of polycarbonate.

Such a plastic roof can be used:

- In urban municipal and private construction of sheds and canopies, transport stops, as well as parking lots.

- Since polycarbonate has high strength, it is used to protect against acts of vandalism as a glazing of vertical, horizontal areas and partitions.

- The exterior of our cities benefits aesthetically, due to the gradual change of deaf stalls to light, transparent pavilions.

- Office, public and commercial centers have become more attractive and spacious due to the arrangement of transparent elements of roofs and partitions, which also have good sound insulation.

- At the moment, cellular and monolithic polycarbonate is widely used in the construction of greenhouses, greenhouses, greenhouses, winter gardens, galleries and studios. At the same time, the video “roof repair: video lesson” posted by us clearly shows that this process when using polycarbonate, as well as the construction of a new roof covering, is quite simple.

In the construction markets, various profiles and plugs are sold, as well as other fittings, which greatly simplifies the work with this sheet plastic.

Ready-made gazebos, greenhouses, sheds, etc. are also for sale. They only need to be delivered to the place and assembled according to the instructions.

Packages with such a peculiar designer weigh very little and are compact. Such a plastic roof can be easily assembled by you with just a screwdriver and a knife.

Did the article help you?