If you have a suburban area, and you plan to spend almost the whole summer on it, then you should definitely make a canopy from the sun with your own hands. This design can be quite simple, but it will protect you from overheating in the summer heat. And if we provide for some nuances, such as a waterproof roof, then you can hide from the rain under such a canopy.

Below we will tell you what such canopies are, and how you can make them yourself with minimal labor.

Varieties of designs

Canopies from rain and sun can be built according to a variety of schemes.

First of all, it should be noted that they are:

- Stationary - installed either on a permanent or temporary foundation. In the second case, it is possible to dismantle the canopy for the winter and reassemble it in the spring.

- Portable - can be installed on any relatively flat area. As a rule, special stakes with stretch marks are used to fix the frame on the ground.

As for the design itself, the most popular include the following models:

- Wall-mounted - regular and folding. As a rule, they are mounted on the load-bearing wall of the veranda or terrace. They can be folded according to the “accordion” principle or rolled up into a compact roller shutter.

Note!

The price of folding structures is quite high, but this is the case when it is better to purchase a finished product: so we can be sure that the mechanism will function correctly.

- Canopies in the form of a large umbrella. Lightweight structures are made portable, but quite often one can also find capital structures of a large area.

- Structures in the form of a roof on several supports. Most often there are canopies on four racks, but in some cases (for example, for a large company) you can use a frame of six or more racks.

The latter variety is the most common, and at the same time, the most laborious in construction. Below we will describe in detail how such sunshades are made.

Structural design

Main dimensions

Before starting work, we need to build a drawing of the future structure. This is done quite simply, but to complete this task, it is necessary to choose the optimal dimensions.

In our case, they will be like this:

- Height structures up to the roof ridge - 2.5 - 2.7 m.

- The height to the roof overhang is 1.9 - 2.1 m.

- The width of the canopy is 1.5 -2 m.

- The length of the structure is 2 - 2.5 m.

Note!

Naturally, deviations from these dimensions are quite acceptable.

On the other hand, you need to be very careful about this stage of work, because it will be inconvenient to use a structure that is too low, or, for example, too cramped.

Tools and materials

Depending on the type of frame and its dimensions, we will need various building materials.

For work we buy:

- Sand and gravel - for filling the area under a canopy.

- Cement - for concreting supports for stationary installation.

- Wooden bars with a section of 40x40 mm for vertical racks.

- Bars 30x30 mm and boards with a thickness of 25 mm or more for the manufacture of the roof frame.

Note!

Supporting structures can also be made of metal.

In this case, we will need to purchase a certain footage of a profile pipe with a section of 30x30 mm and a steel corner.

- Fasteners for frame assembly.

- Composition for the disinfection of wood or for the protection of metal from corrosion.

As for the roof, then it is used for:

- Polycarbonate (it is better to take tinted).

- Dense fabric for a canopy from the sun. For the manufacture of fabric covers, a tarpaulin or other dense material is suitable, as well as a polymer fabric made of polyamide threads impregnated with vinyl.

- Self-tapping screws for polycarbonate or cords for fixing the cover to the supporting structures.

A set of tools for construction will be quite typical:

- Trench tool for earthworks.

- Roulette and measuring cord.

- Saw for wood or metal (it is better to take disk models).

- Hand tools (hammers, chisels, pliers, etc.).

- Welding machine (used if the frame is being built from metal).

As you can see, there is nothing complicated, and large-scale spending is clearly not required. When everything is ready and the tool is at hand, we can begin the installation of the canopy.

Manufacturing technique

canopy base

Instructions for arranging a canopy begin with a description of the preparation of the base:

- We choose the place that is best suited for relaxation. It is good if it is located behind the house: then the building will not only hide it from prying eyes, but also protect it from the wind.

- It is also desirable that the plot of land under the canopy be fairly flat. Of course, you can remove part of the soil and level even an inclined platform, but in this case the labor intensity of the work will increase significantly.

- On the prepared site with the help of cords, we apply markings.

- By marking, we take out a layer of soil up to 15 cm deep.

- In the corners of the resulting recess, we drill nests for installing supports. The holes are temporarily closed to avoid falling asleep.

Advice!

If you plan to install a stationary table under a canopy, you can also drill nests for the legs in advance.

- Along the perimeter, we install either a wooden blind area made of thick boards impregnated with an antiseptic, or made of curb stone. It is desirable that the protrusion of the blind area above the ground does not exceed 10-15 mm.

- We fill the recess with a sand-gravel mixture. We moisten the material and carefully compact it.

Frame installation

Next, proceed to the assembly of the frame:

- We cut the bars or pipes for vertical supports to size, taking into account the length of the part buried in the ground.

- At the bottom of each nest for racks, we fill up a mixture of sand and gravel, which we carefully tamp.

- We install the supports and align them with a water level. We fix each part with rope stretch marks or temporary wooden supports.

- Then we concrete the supports, pouring a solution with the addition of gravel into the holes. To strengthen the structure, it is also possible to introduce broken ceramic bricks, pieces of reinforcement, cast-iron shot, etc. into the concrete composition.

Advice!

Holes filled with concrete should be closed with polyethylene for about 7-10 days: this way the moisture will evaporate more slowly, and the solution will have time to gain strength.

- After the initial fixing of the supports from above, we connect them with thinner bars or pipes, forming the upper harness. You can also strengthen the supports with struts or cross bars (they will also play the role of a railing).

Stationary roof

In its form, the roof of the canopy in the country house can be different:

- The most common design is semi-circular. As a supporting frame, metal arcs from a profile pipe are used here, for the manufacture of which a pipe bending machine is used.

- Gable roofs are erected somewhat less often. In this case, we install two or three pairs of rafters from a board about 25 cm thick on the upper harness.

- A hipped roof is also constructed from the same material, but it is usually made only over square canopies.

- An important element is rafter overhang - protrusion of the frame outside the structure. The larger this overhang, the less drops will fall under the roof during rain, and the better the protection from the sun will be.

Note!

Too much overhang limits the view, so you should not get carried away in this case.

As a roofing material for a canopy, a polycarbonate sheet is best suited.

It is mounted like this:

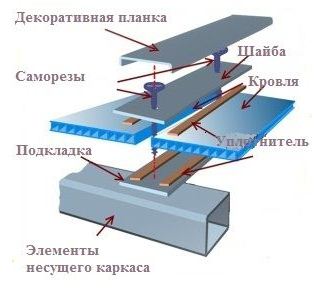

- We cut the tinted polycarbonate panel to size with a knife or a fine-toothed saw.

- We put on a special protective or connecting profile on the ends, which prevents moisture from getting inside.

- We fasten the polycarbonate to the rafters with special self-tapping screws, clamping them with such force that the material under the polymer washer does not deform.

- We install gutter strips at all corners of the roof, otherwise we cannot avoid leaks!

Fabric case

Another roofing option is a fabric cover that can be mounted on the frame:

- For the manufacture of the cover, you can take a variety of materials. A thin impregnated tarpaulin or tent fabric is well suited, and polymer materials also demonstrate good efficiency.

- Cotton and calico canvases can also be used, but they only protect from the sun.

Advice!

When buying materials for the cover, do not forget to purchase a few meters of fine mesh - it will come in handy when arranging the mosquito net.

- A canopy made of fabric or polymer can be purchased ready-made.The easiest way to do this is in a company that manufactures commercial equipment and advertising paraphernalia: as a rule, such manufacturers have a very wide range of different tents.

- At the same time, self-production should also not be particularly difficult: it is enough to purchase fabric, cut it according to a pattern and carefully stitch it. For stitching, it is best to use a semi-professional sewing machine - it is guaranteed to cope with dense fabric.

- Along the perimeter of such a canopy, we mount eyelets - holes with a metal edging. We pass a nylon cord through the eyelets, which we use to attach the fabric to the frame and for stretch marks.

Conclusion

As you can see, a country or beach canopy from the sun can be made independently, while the cost of purchasing materials will be relatively small. Of course, the more carefully the work is planned, and the more accurately you perform all operations, the better the result will be. That's why before you get down to business, we advise you to watch the video in this article: most likely, you will find a lot of useful and new information in it!

Did the article help you?