After the roof truss structure is ready, it is necessary to immediately start roofing work to prevent the negative effects of precipitation on wooden parts. Consider how a roof can be built with your own hands.

After the roof truss structure is ready, it is necessary to immediately start roofing work to prevent the negative effects of precipitation on wooden parts. Consider how a roof can be built with your own hands.

The choice of material for roofing

One of the most responsible and difficult tasks is the choice of material for roofing.The complexity of the issue lies in the fact that there is no ideal roofing material that could be recommended for any home, so it is necessary to evaluate the pros and cons of all possible options.

Today, a huge amount of roofing materials has been created. Among the most commonly used:

- Slate or ondulin;

- Decking;

- Sheets of metal;

- Ceramic tiles;

- Soft tiles;

- Cement-sand tiles;

- Polymer-sand tiles;

- metal tile;

- Roll materials, etc.

In addition, sometimes natural materials are used to create a roof - reed stalks, straw, turf.

When choosing one or another option, you have to consider many factors, including:

- Roof structure (flat, pitched, domed, mansard, etc.)

- aesthetic component. Roofing material must be in harmony with the overall architectural design.

- Economic aspect. When choosing a material, you have to take into account its cost in order to meet the budget. But it should be remembered that more expensive materials allow you to create durable coatings that will last for decades. While a cheap version of the roof may require repair in 5-7 years.

It should be noted that the most popular materials for roofing are metal tiles and corrugated board. However, you should not focus only on the named option. In each case, it is necessary to make a choice taking into account all existing factors.

Stages of roof construction

Of course, the construction of a roof cannot be called a simple and easy process. However, if desired, it can be done on your own.

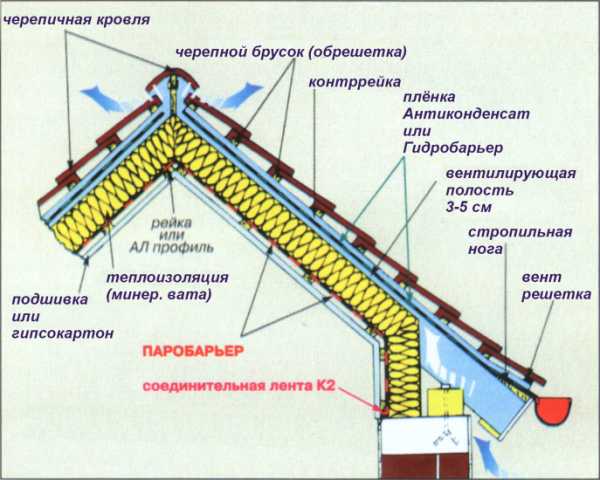

The first thing to learn is that any roof, regardless of the chosen roofing material, is a multi-layer structure, which builders call the “roofing pie”.

The composition of the roof includes, as a rule, a crate, a layer of vapor barrier, a layer of insulation, waterproofing and a top roofing. The number of layers and their composition may vary depending on the chosen laying technology and the climatic conditions of the area where the house is being built.

Construction of the crate

The first layer of the roofing cake is roof lathing, which is mounted on top of the rafters. The type of lathing is determined by the material that is chosen to cover the roof.

So, for a soft roof made of rolled materials, a continuous crate is required. For laying a profiled sheet, ondulin or metal tiles, a crate made with a certain step is also perfect.

Advice! Plywood or similar sheet material can be used to build a continuous batten. The crate with a step is made of boards 20-25 cm wide.

When building a crate, it is imperative to make an overhang. It may be small, but it must be done around the entire perimeter of the building.

The overhang will be used for the roof eaves, which will protect the house from moisture during rains accompanied by wind.

Vapor barrier installation

The next step in creating a roofing pie is a vapor barrier device. This layer is necessary to prevent the formation of condensate on the insulation, due to the evaporation of moisture from inside the room.

Today, membrane films are used as a vapor barrier material, which are installed on the inside of the insulation (between the thermal insulation and the interior decoration of the room).

There are several types of vapor barrier for roofing:

- standard;

- With a reflective layer. Such a vapor barrier, due to the presence of a reflex layer, reflects part of the heat back into the interior of the premises. In addition, such membranes have a higher vapor permeability than standard ones, so they are recommended to be installed in rooms where air humidity is high.

- With limited vapor permeability. Such membranes are an ideal solution for houses that are used only occasionally (country cottages, summer cottages).

- With variable vapor permeability. Such films are recommended for mansard roofs.

In addition to the membrane itself, for an effective vapor barrier device, you will need a special adhesive tape, which is used to connect individual canvases and to glue the places where the film adjoins the walls.

Roof insulation

Today, almost all roofs are made warm, so the next step, which involves the construction of a roof with your own hands, is the laying of insulation.

Being a building envelope, the roof is operated in a fairly tough mode and experiences large temperature fluctuations. So, the lower part of the roof (the ceiling of the room), as a rule, has a temperature close to room temperature.

While the outer part of the roof either warms up to +100 degrees (on a sunny summer day), then cools down to -50 (in frost with wind load). At the same time, the entire structure must reliably protect the interior from both heat and cold.

The thermal insulation of the roof is provided by materials with a low degree of thermal conductivity.

As a heater, most often used:

- Mineral wool;

- glass wool;

- Styrofoam;

- Loose insulation (expanded clay, sawdust, etc.).

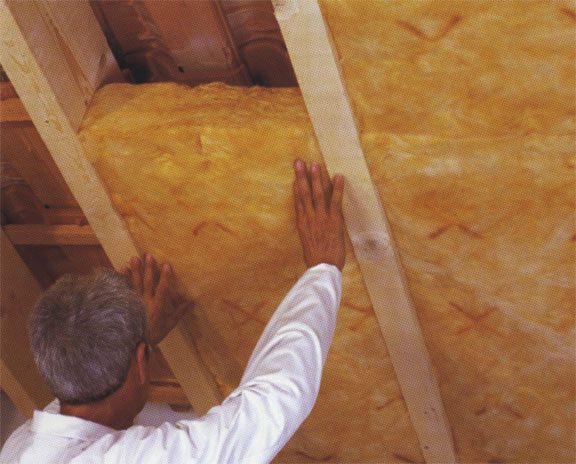

The process of laying material for thermal insulation includes the following operations:

- Measuring the thickness of the rafter legs and measuring the distance between them;

- Preparation of plates from heat-insulating material.

Advice! When using mineral wool, the width of the slab should be one centimeter greater than the distance between adjacent rafters, and the thickness of the slabs should be about 2-3 cm less than the height of the rafters.

- To insulate the eaves, two strips of plywood are used, which are placed in an opening located between the rafter legs and the cornice overhang. Then, insulation boards descend along these strips of plywood.

- Insulation plates are laid over the entire surface of the roof, right up to the ridge itself. Using the trimmings that were formed during the formation of the main insulation plates, a heat-insulating layer should be made around the pipe and the openings of the skylights.

Thermal insulation boards can be fastened with mastic or glue, or with nails and screws.

Roof waterproofing

Roof waterproofing is a necessary measure designed to protect the inner layers of the roof from the damaging effects of atmospheric influences.

If you do not perform waterproofing, then the roofing will not be able to withstand precipitation and wind for a long time and will have to be repaired after a short time.

You may need a complete replacement of the roof with your own hands or an order for this work to be done by employees of a repair and construction company.

The materials used for waterproofing should be:

- One hundred percent waterproof;

- Durable and resistant to mechanical damage;

- Elastic.

Another of the desirable requirements for the material is the heat-saving ability.

Traditionally, bituminous materials were used as waterproofing - roofing material, hydrostekloizol or glassine. In modern construction, preference is given to more advanced materials based on fiberglass or polyester impregnated with a polymer-bitumen composition.

Such materials are more durable and have better performance characteristics.

In addition, mastics and liquid spray coatings are used for waterproofing.

It is especially convenient to use liquid materials to create abutments. When hardened, the mastic turns into a coating that resembles rubber. Such a coating is very durable and quite elastic.

Laying roofing material

The technology of laying the material depends on its type. Consider how work is performed using the most popular materials.

Soft roof. If earlier, mainly roofing material was used to create a soft roof, today more modern polymer-bitumen built-up roofing materials.

It is more convenient to carry out work on laying the deposited materials with two people. The first person, using a gas burner, heats the surface of the roof and the lower part of the rolled material. The second one rolls out the heated material and rolls it with a roller, achieving a tight fit to the base.

When installing a soft roof, the material is laid in two or more layers, so that the seams between the two panels are not one above the other.

When performing a multilayer soft roof different types of material are used. Lining material is placed down, and covering material is placed on top. Roof overhangs, ridge, pipe outlet are decorated with aprons made of roofing steel.

The main disadvantage of bituminous materials is their poor fire-fighting qualities. But with the use of rolled soft materials, a non-combustible roof can also be created.

For this, a material based on synthetic rubber is used. Such coatings are highly resistant to fire, tightness, elasticity and a high level of strength.

Self-leveling roof. Self-leveling roofs, recently, are becoming increasingly popular, but they are rarely done by hand, since professional equipment and precise knowledge of the rules of work and one material or another are required to obtain a high-quality coating.

Ondulin roof. Mounting ondulin is easy, so such work is often done by hand. Mounting Tips:

- It is convenient to mark the sheets with a colored marker, and you need to cut them with a hacksaw for wood or an electric saw.

- You need to start fastening the sheets from the edge of the roof, which is opposite to the direction of the prevailing winds.

- It is necessary to nail ondulin along each wave along the edge of the sheet and along the side overlap;

- It is convenient to use a stretched rope as a level.

- When installing ondulin, you need to walk on already fixed sheets, stepping on waves, and not on depressions.

- The fastening of the ridge element is carried out by nailing on each wave of the sheet adjacent to it.

- To properly use the valleys, you need to arrange additional crates.

Metal roof. If a fireproof roof is mounted, then you can use a galvanized steel profiled sheet. Here are some helpful tips to get the job done:

- When laying corrugated board, fastening is carried out using self-tapping screws, which are screwed into the deflection of the sheet.

- Places on cuts of sheets must be covered with enamel for polymer coatings to prevent corrosion.

- Chips that form when screwing in self-tapping screws must be removed from the coating. Otherwise, they will begin to rust and may ruin the new roof.

- The protective film on the polymer coating must be removed immediately after the sheet has been installed. Otherwise, it may “stick” to the sheets and the coating will look unaesthetic.

Conclusion

Doing roofing work with your own hands requires building skills and knowledge of technology.

In the absence of experience, you can start work, only with the most simple materials in laying. But to take on the creation of a roof made of copper or reed, without having the appropriate skills, is not worth it.

Did the article help you?