In this article we will talk about what a shed canopy is and how it differs from other canopies. In addition, we will consider the main list of materials used in the construction of such structures.

The topic of the article is relevant from different points of view, since the construction of a light canopy allows you to save money on the construction of a full-fledged garage or outbuildings. The construction of a canopy with a shed roof is an effective solution for landscaping areas adjacent to a country house or cottage.That is why this topic is of particular interest with the beginning of the summer season.

Design features

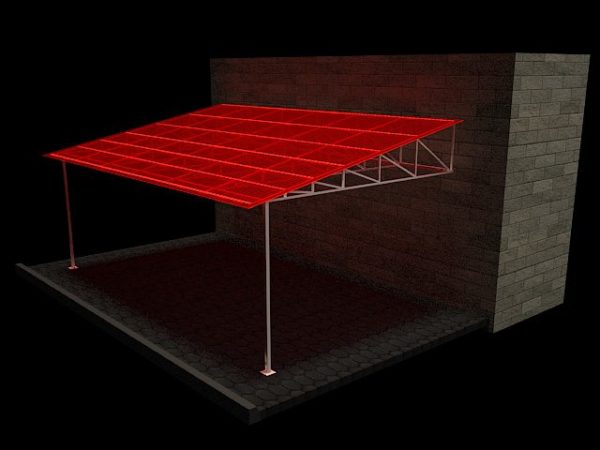

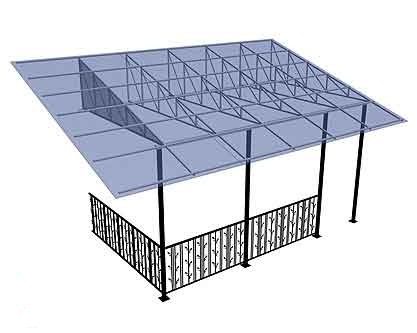

The canopy is a structure consisting of racks, a frame that replaces rafter system and roofing. The rafter system has a slope in one direction and this is the main difference from the gable counterpart.

Due to the design features, shed canopies with a higher side, most often, adjoin the main construction site.

Important: Due to the design features of the canopy device, there is a unique opportunity to save money when assembling the drainage system with your own hands.

The frame and uprights can be made from different materials such as metal, wood, brick, etc. Roofing is selected in accordance with the design features of the frame.

For example, for structures with brick supports, slate or corrugated board can be used. If the canopy is a lightweight structure made of metal pipes or wooden beams, it is advisable to use sheet cellular polycarbonate, polyester, triplex tarpaulin, impact-resistant tempered glass, and in some cases dense polyethylene.

Scope of application

In accordance with the design features, the scope of canopies is determined, which are used as a light temporary roof during the device:

- terraces and country summer verandas

- car parks;

- children's playgrounds;

- recreation areas on personal plots;

- street outlets.

Of course, the list of applications for this type of canopies is much wider than the proposed list, and if necessary, it will always be possible to decide how to apply this design for its intended purpose.

Now that we know that light canopies are distinguished by an affordable price and many other equally relevant advantages, we will consider the technology for manufacturing these structures from various materials.

Assembly from a profile metal pipe

Before proceeding with the assembly, we will perform the calculation of a shed canopy, on which the strength and price of the finished product will depend.

The calculation depends on the type of roofing material to be used and on the climatic conditions characteristic of the region. If the winters are snowy, then the structure is welded from thick-walled pipes with a large diameter and metal corrugated board is used instead of cellular polycarbonate.

If precipitation is low in winter, less expensive smaller diameter pipes and lighter covering material can be dispensed with.

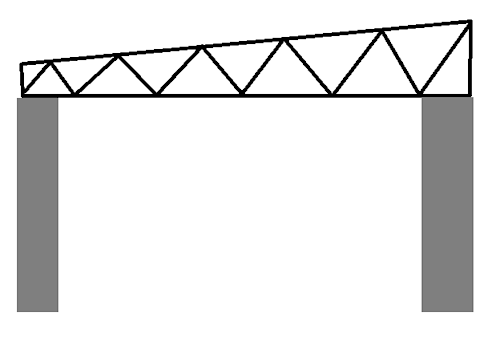

On average, in order to assemble single-sided polycarbonate canopies, the following square pipes can be used:

- racks - cross section 25x25 mm (based on 6 supports, if the supports are smaller, the pipe section increases);

- lower and upper details of trusses - 20x20 mm;

- inclined truss struts - pieces of steel bar with a diameter of 10 mm.

The given sizes are relevant if a shed canopy with a width of 6 m is being built.With a larger width of the structure, it will be necessary to use pipes with an increased wall thickness and with large cross-sectional dimensions.

The assembly instructions for this type of metal structures are not difficult if all the necessary tool.

For work you will need:

- welding machine;

- angle grinder (grinder) with discs for metal;

- clamps for temporary fixation of pipes;

- screwdriver;

- measuring accessories.

We assemble the canopies as follows:

- We cut the racks with the expectation that they will have to be buried half a meter into the ground;

- We cut pipes for assembling trusses;

- We cut the bar for the device of inclined jumpers;

- Putting together the structure of the trusses and welding at the joints;

- We fix the trusses on the longitudinal beams with the help of clamps and cook the joints;

- We dig holes for supports, install racks in them, position them in a perpendicular position and fill them with concrete;

- After the concrete has gained proper strength, the upper part of the structure is lifted onto the racks and welded;

- The roofing material is cut in accordance with the dimensions of the assembled structure and mounted using self-tapping screws.

Important: When installing polycarbonate, the self-tapping screws are not completely screwed in, but a gap is left for thermal expansion of the material.

Lumber assembly

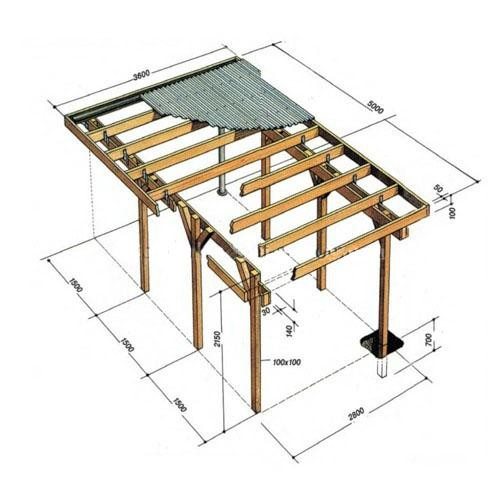

Shed canopies made of corrugated board and a frame made of wooden beams are assembled during the arrangement of country houses and summer cottages. Such structures are mainly used as summer verandas and covered terraces.

Important: Unlike the installation of metal structures, in this case we will need special fastening hardware, since the assembly of a wooden frame involves the use of a bolted connection.

As a tool, you will need a wood saw, a drill with a screwdriver function, a chisel, a hammer and measuring accessories.

Immediately before assembly, we cut racks, crossbars and truss parts from a 100x100 mm beam. We impregnate all blanks with an antiseptic solution that will prevent the wood from rotting. The assembly of individual elements is carried out with a half-tree connection and fastened with bolts.

The supports are buried in the ground and concreted. But before that, the ends of the supports are covered with a layer of bituminous mastic or upholstered with tin. Roofing on a wooden frame is also mounted using self-tapping screws.

Conclusion

Now we have a general idea of what a shed type canopy is, for what purposes it is used and from what materials it can be made. In addition, we examined how a shed canopy is assembled from a profile pipe and its wooden counterpart.

You can find a lot of useful information by watching the video in this article.

Did the article help you?