The installation of a roof is a rather complicated task, the solution of which requires compliance with a number of requirements that apply to modern roofing materials, as well as norms for heat, hydro and vapor barrier.

The installation of a roof is a rather complicated task, the solution of which requires compliance with a number of requirements that apply to modern roofing materials, as well as norms for heat, hydro and vapor barrier.

A properly installed roof will ensure a long service life of the entire structure.

Roof device features

Roof covering, as a rule, consists of the following elements:

- Skates (inclined planes).

- Skates (horizontal ribs).

- Inclined ribs.

The places where the slopes intersect at the entrance angle are called grooves and valleys.The inclined and horizontal edges of the roof extending beyond the structure are called gable and cornice overhangs, respectively.

Rainwater flows from the slopes into the gutters of the drainage system, from where it enters the funnels-water inlets, and then into the drainpipes and storm sewers.

Roof elements can be laid both in transverse and longitudinal positions, connecting in a lock (roofing sheet steel) or overlapping (other types of coatings).

Roofs are:

- Single-layer - from asbestos-cement sheets or slabs, from steel sheets, from seam, stamped and tape tiles.

- Multilayer - from flat strip tiles, rolled materials, shingles, shavings, tesa, etc.

The number of layers of multi-layer roofs usually ranges from 2-5 depending on the type of material used. They are less economical and more labor intensive.

Roof pitch provides removal from a roof of an atmospheric precipitation. It is usually expressed as a percentage or degrees. When constructing structures, their roofs are made flat with the same slope angles.

The chosen slope of the roof affects the choice of roofing, as well as the method of draining water from the roof - organized and unorganized drainage.

Arrangement of roofs made of soft materials

The device of this type of roof consists of the following:

- arrangement of an internal drainage system (if necessary);

- device for vapor barrier leveling screed;

- vapor barrier device;

- thermal insulation device;

- demolition device with sand;

- arrangement of funnels of the internal drainage system;

- device of a coupler from sand and cement;

- the device of a roofing carpet at aerators and funnels;

- organization of a two-layer type roofing carpet on a plane;

- arrangement of a roofing carpet at the junctions with protruding structural elements and parapets;

- installation of steel parapets and aprons at the junctions (galvanized or polymer steel coating);

- painting the roof with fire retardant and reflective composition (if necessary).

The device of a polymer-membrane roof

The use of single-layer membranes as a roof covering can provide a high speed of roof installation. Rolls of different widths (1-15 m) are presented on the market, and thanks to this, do-it-yourself roofing is possible with a minimum of seams and almost any complexity.

The technical features of the membranes and their accessories make it possible to carry out installation work throughout the year without changing the technology.

Roofing methods using polymer membranes for pitched and flat roofs:

- mechanically fixed system;

- ballast system;

- adhesive system;

- rail-in-seam system.

The method of fixing the membranes is selected based on the design features of the base and the structure as a whole. Often in these cases, material manufacturers give their recommendations regarding the choice of one method or another.

Arrangement of a rolled roof

Roll materials, even with a zero slope, are able to provide complete water tightness, while the maximum recommended slope for such roofs is 45-50 degrees. Their installation can be made on any solid base (concrete, wood, etc.).

There are a number of basic methods for laying rolled materials, based on which the coatings are divided into:

- glued

- on cold bitumen-polymer, rubber-bitumen, polymer mastics and adhesives;

- on hot mastics for roofing bituminous;

- built-up:

- on modified and oxidized bitumens;

- fire (hot) method using a gas burner;

- fireless (hot) method using equipment that creates infrared radiation;

- fireless (cold) method - by dissolving a thickened bitumen layer.

Advice! Fiberglass, fiberglass or polyester (polyester fabric) is used as the basis for the welded materials.

- having an adhesive layer: such materials have a protective coating (paper or silicone film) on the inside, which is removed and then rolled onto a primed surface.

The oldest method of installing a roofing carpet is the method of continuous gluing of materials to the base. However, in some cases it may be more appropriate to lay with the so-called partial gluing.

This eliminates the conditions for the formation of excess pressure due to the occurrence of an air gap between the base and the roof, which communicates through the exhaust vents or along the roof contour with the outside air.

This is the so-called breathable roof.

Rafter roof installation

The device of the roof truss from inclined rafters consists of the following steps:

- installation of beds and Mauerlat;

- installation of racks and skates runs;

- installation of struts and rafter legs;

- crate installation;

- installation of vapor barrier;

- thermal insulation devices;

- waterproofing installations;

- roofing installation.

Almost the entire support for the roof consists, as a rule, of wood - beams, boards, slats, mainly from conifers.

Beds and mauerlat are installed on two layers of waterproofing material previously laid in the upper part of the walls.

The components of the truss system of beams and boards, among other things, are interconnected using cuts. Cross-shaped intersections of the bars are connected in half a tree.

Struts and rafter legs are installed as follows:

- make a breakdown on the mauerlat of the position of the rafter legs according to the project;

- build nests in the Mauerlat;

- mount inventory scaffolding;

- install rafters based on a ridge beam and a Mauerlat;

- check the compliance with the design position of the mounted components, after which they fasten the truss system with bolts and brackets;

- the joints of the rafter legs are subjected to additional treatment with an antiseptic solution.

The conjugation of structural elements is carried out using nails, staples, reinforcing linings. The load-bearing components of the roof are made of boards with a section of 50 * 150mm. On the butt sections, double plank linings up to 30 mm thick are nailed. Nails should be three times the thickness of the boards and bars they nail.

After the installation of four rows of rafters, the flooring of the crate begins. The bars are nailed according to the pattern in the direction of the ridge from the eaves.

The design step in this case will depend on the type of roofing used and its design features. Solid plank flooring is laid along the overhang of the roof above the eaves, on the grooves and the ridge, under the joints of the sheets.

The roofing is completed by cutting openings for dormer windows and manholes in the crate.

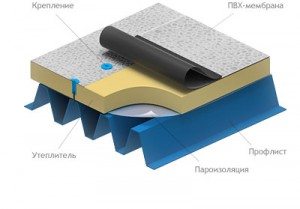

The layers of the roofing cake are arranged from the bottom up, starting from the attic space, in the following sequence:

- vapor barrier - to protect the insulation from saturation with water vapor rising from the interior of the structure;

- roof insulation- to reduce the thermal conductivity between the interior of the building and the environment;

- air layer - for ventilation (output of moisture accumulating in the insulation); layer thickness at least 50 mm;

- roof waterproofing- to prevent penetration into the lower layers of the cake of possible leaks of the roofing and the resulting condensate;

- roofing roof covering - the main barrier that protects the structure from precipitation and other influences.

Advice! It is important to keep the insulation in a dry state, since the moistened material loses its thermal insulation qualities almost completely.

The choice of the type of roof depends primarily on the preferences of the developer and the features of the structure. However, in any case, only a competently executed roofing device will help to make a really high-quality roof.

Did the article help you?