When performing roofing work, various roofing tools are used, which will be discussed in more detail in this article.

In addition, the article lists the main methods for sharpening roofing tools.

Basic hand tools

The following are the main roofing tools used in manual labor:

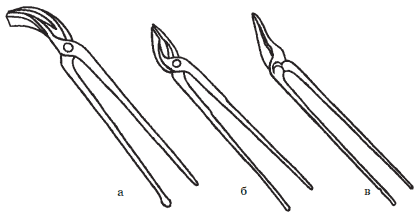

- Ticks - a manual roofing tool used in the process of assembling metal sheets when bending their edges is required.

There are curved (a), semicircular (b) and straight (c) pincers.The jaws of the straight pliers are straight and do not damage the galvanization.

Semi-circular tongs are used when performing such operations as bending, finishing various shaped elements, stripping coatings and gutters, etc. Curved pliers are used when assembling hard-to-reach areas house roofs .

Roofing pliers

- A roofing hand tool, with which standing folds are bent, is called an edge bender.. It has a longitudinal slot in the middle, the height of which is from 25 to 35 mm.

- riveter - a manual roofing tool designed for splicing parts in the form of sheets.

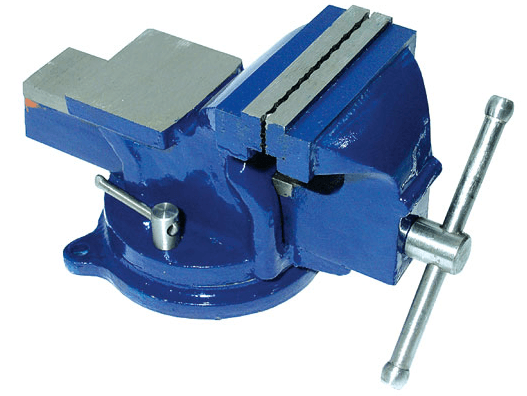

- Vise, designed for clamping, are divided into chair and parallel. Both those and other vices are two sponges (movable and fixed) and a lever that rotates the screw. When performing work, the vise is fixed on a workbench.

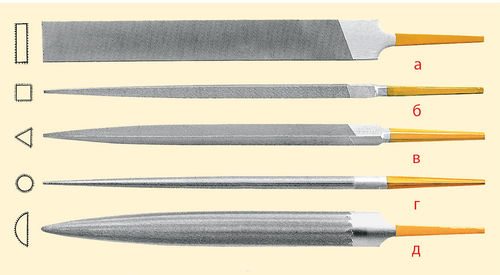

- For filing, that is, removing the top layer from the surface of the part, various types of files are used., consisting of a body, nose, shank and heel and having notches on the working surface, allowing you to remove layers of metal.

Files There are different sections of files: rectangular, round, square, triangular, semicircular, etc.

Consider the different types of section in more detail:

-

- Rectangular (a) is universal, used in finishing almost any surface, including shaped ones;

- square (b) - used when processing rectangular surfaces;

- triangular (c) used for finishing corners and triangular holes;

- Round (d) used for round holes;

- semicircular(e) designed for processing concave surfaces.

In addition, a roofer's tool may include special files.Their cross section can be oval, diamond-shaped or sword-shaped.

Tools used to make and process various holes

The following roofing tool is used to make holes:

- spiral drills;

- electric and hand drills;

- various drills, etc.

The drill consists of a working part, a shank, a machine and a foot. The working part can be cutting or cylindrical. The shank is placed in the spindle - a rotating shaft equipped with a drill holder.

To divert to the side the chips flying off during the drilling process, the cylindrical part of the drill is equipped with two helical grooves with ribbons along the edges, which reduce the friction of the drill on the edges.

The cutting part of the drill is made in the form of a cone, on which there are two cutting edges and one transverse one. Depending on the metal from which the workpiece is made, the sharpening angle is chosen in the range of 110-150 degrees.

In addition, the following roofing tool is used to make holes:

- Countersink, designed for processing cylindrical or conical recesses. With the help of a countersink, holes drilled under the heads of bolts, screws and rivets are also processed.

There are two types of countersink. A cylindrical countersink includes a shank, a working part with 4-8 teeth and a guide pin, which is lowered into the hole to align its axis with the recess made by the countersink. The conical countersink consists of a working part and a shank.

The most common countersinks, the cone angles of which are 60, 90 and 120 degrees.

Countersink

- A countersink is used to finish holes resulting from various methods such as forging, stamping, casting or drilling..

It looks like a drill, but unlike it, it has not two cutting edges, but three or four. If the hole will be finished with a countersink after drilling with a drill, a drill should be taken, the diameter of which is less than the planned diameter of the hole.

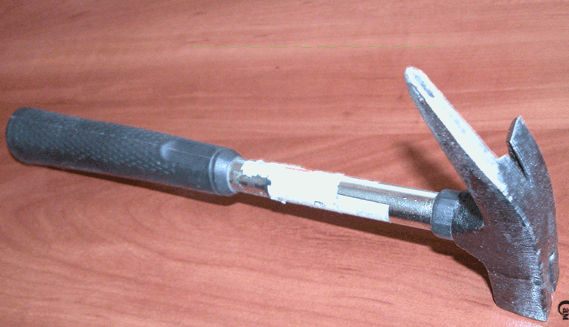

- To make various holes, a punch is also used, which can be used as a special roofing hammer.

Tool sharpening

In order to work on roofing installation were carried out efficiently and did not require a lot of labor resources, the proper condition of the tools should be monitored.

At the same time, it is most important to control the sharpness of sharpening tools such as a roofing knife, etc.

There are three main sharpening tools:

- winepressused for sharpening cutting tools.

winepress The main points when sharpening with a sharpener are given below:

-

- Coarse grindstones leave scratches and nicks that are then removed with fine grindstones;

- In the process of sharpening planers, chisels and chisels, a round whetstone is directed towards the blade;

- The point should lie entirely on the surface of the sharpener, which should be periodically moistened with water to prevent annealing of the steel;

- After sharpening, the point should be slightly rounded to avoid the appearance of nicks on it.

- whetstones, made of sandstone, are used for rough sharpening of tools. Large grains allow you to remove metal quite quickly.

Before use, the bar should be slightly moistened, after which it is fixed and the chamfer of the tool is pressed against it, which is moved along the bar back and forth. After sharpening on a bar, the blade is adjusted with a whetstone.

whetstone

- Sharpened blades are used to grind sharpened blades, as well as to remove burrs from them.. The touchstone is moistened with water or lubricated with machine oil, after which the blade is driven over it in a circular motion, alternately pressing on both sides.

The procedure is performed until a smooth shiny surface is achieved.

Touchstone - Files are also used to sharpen a number of tools.. So, the saw is sharpened with a trihedral file.

To do this, the teeth of the saw are set so that their height and width of the set are the same in all sections.

Sharpening drills for metal is carried out using corundum or emery stones and grinding discs.

Useful: in case of a slight dullness of the drill, it should be sharpened with a fine-cut knife file. To do this, perform light counterclockwise movements.

Sharpening scissor blades is performed at an angle of 70 to 74 degrees. In this case, the back angle of the blades should be 2-3 degrees, which can significantly reduce the friction of the knives.

When embarking on the construction or repair of a roof, you should prepare in advance all the necessary tools for which must be stored in proper conditions. In addition, it is important to keep the tools in good condition, which can greatly facilitate the work and reduce the propane consumption on the roof.

Did the article help you?