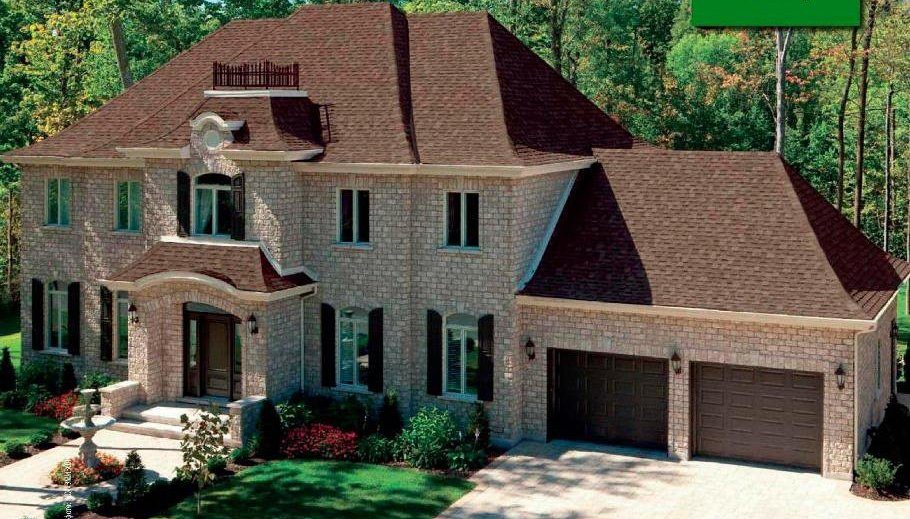

Very often, when building your country house, at the stage when the work is approaching the creation of a roof, problems begin. Since many simply do not know all the elements of the roof and roofing accessories necessary for its creation.

Therefore, let's pay special attention to this issue in this article. And consider the example of a simple roof with bituminous tiles.

The load-bearing walls of your house are completed and it remains only to put the roof. And it is better not to delay this issue, since without a roof there will be destruction of materials due to precipitation. The first thing you need is to calculate the surface area of the roof, its windage and the total load on the building.

For this, it is best to contact professional architects. Because the elements of roof safety are directly related to their calculation.

But let's move on to considering what details of the roof are used, these are:

- Waterproofing.

- Mauerlat.

- Cover beam.

- Rafter.

- crate roofs.

- Roofing material.

These are the main roofing elements and now in more detail about each of them.

So:

- Waterproofing.Before laying the Mauerlat belt and fixing other main components of the roof structure, it is necessary to carry out waterproofing work. To prevent moisture from entering the room.

Basically, a simple construction roofing material is used, which is cut to the required width of the bearing wall. - Mauerlat. The Mauerlat belt is made of wood or metal, depending on the material from which the load-bearing part of the roof will be made. But basically it is a wooden beam with a section of 150x200 mm or 100x200 mm, depending on the type of load-bearing wall.

This belt is designed to fasten the main load-bearing structural elements and distribute the load evenly over the wall area.

It is very important that the Mauerlat ball is securely fixed to the wall. Therefore, fastening can be done in several ways:

-

- Fastening with reinforcing wire, which is fixed directly in the wall structure or masonry.

- Fastening with studs, directly through the wood. For more reliable fixation, large metal washers are used, which increase the fixation area.

Important: this is a very important element of the roof structure and overall safety depends on the reliability of its fastening. Therefore, be very careful when making it.

Now let's look at the shaped elements of the roof, namely the rafters and floor beams and the roofing material itself:

- floor beams. These structural details can be made of both wood and metal. Depending on the requirement for the attic floor.

At the same time, the choice of material has practically no effect on the materials in other elements of your roofs (that is, if the rafters are made of wood, this will not greatly affect the overall roof structure). - rafters. This is the main load-bearing part of the roof, which can be made, like the previously described elements, from metal or wood.

But nevertheless, the main distribution was received, wooden stops. For their manufacture, a beam of 150 mm * 150 mm is used, or a cut board of 150 mm * 50 mm, if the total load from the roofing material used allows it.

The most common rafter pitch is 800 mm, but if it is necessary to strengthen the roof, the distance between them can be 500 - 600 mm. Between themselves, before creating a supporting crate, they can be fastened with a ridge board or a ridge beam in the lower part of the upper connection of the elements of the truss system.

Also, the fastening to the Mauerlat belt can be different, for example, such as:

- With the help of metal brackets in the side of the rafters and Mauerlat.

- With the help of metal corners in the side and nails hammered directly through the top of the rafters into the Mauerlat belt. But with such an attachment, the junction is usually cut to the required angle.

Lathing for fastening roofing

Its manufacture directly depends on the chosen roofing material.

So let's take a look at several options:

- Creating a crate for fastening slate and corrugated board. For these materials, it makes no sense to make a completely closed flat surface.

Since this will reduce the overall weight of the roof. For slate, a crate is created in increments of 500 - 600 mm, for normal fixation of sheets, and for corrugated board, it is advisable to do it in increments of 500 mm or a little more often.

Since this is a thin sheet material, and with a greater distance between the elements it can sag. - Creation of a carrier crate for ondulin and shingles. These are soft fibrous materials that can deform when heated.

For this reason, the frame must be solid. For its manufacture, both wood (board) and OSB (sawdust chipboard) are used, which allows you to create an almost flat surface.

We have dealt with these elements, and I think it makes no sense to list the types of roofing materials. Since we considered some of them when creating crates.

Important: before installation, all wooden roof elements must be treated with special antifungal and fire-fighting agents. This will significantly increase the life and safety of your roof.

Did the article help you?