The climate of our country is characterized by temperature fluctuations and a considerable amount of precipitation, which in the cold period for many owners of private houses is fraught with avalanches from the roof of snow and ice, the formation of life-threatening icicles along the edges of the roof.

In order not to fear for your own life, and also not to repair the gutter system every season, you should turn your attention to the anti-icing systems of the roof and gutter.

Why install an anti-icing system

With the help of such a system, it is possible to eliminate the likelihood of the appearance of various types of ice on the edges of the roof, gutters and pipes, and other places where it is likely to occur.

Why you should be wary of ice formation:

- Massive accumulations of ice during separation create a real danger to the health and life of people, and also often cause significant material damage in cases of falling on the underlying architectural elements of the building, nearby vehicles, etc.

- The retention of ice and snow on the roof surface during the thaw period due to an ice-blocked drain can provoke a roof leak, as a result of which water can penetrate into the living quarters.

Advice!

Mechanical cleaning of the roof surface from snow and ice not only requires a lot of time and effort, but can also somewhat reduce the life of the roofing material due to friction.

When properly designed and installed, an anti-icing system can provide the following benefits:

- Ensure continuous and full-fledged operation of the drain throughout the year.

- Prevent damage to the pipes of the drainage system, facade elements, exclude leaks due to accumulation of precipitation.

- To prevent the appearance of icicles and frost at relatively low capital costs and economical energy consumption.

Design of the anti-icing system

Anti-icing system, as a rule, consists of the following structural elements:

- Heating sections - heating cables for roofing length determined by the project, wired and prepared for connection to the mains with standard domestic voltage.

- thermostat.

- Mounting boxes for the possibility of branching and connections.

- Electrical installation products (magnetic starters, RCDs).

- Fasteners - cables, clips, brackets, swing hooks, mounting tape, brackets, rivets, screws, dowels and more.

Types of heating cables

For the installation of icing systems, one of the following types of cables is usually used:

- resistive;

- self-regulating.

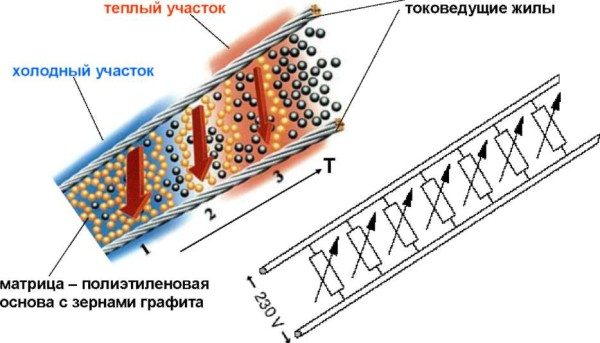

The resistance cable is heated by means of ohmic losses in the heating cable core. In addition to the heating cable, such a cable may also contain a conductive core, which facilitates the process of its connection. However, the power of this type of cable does not depend on temperature conditions, therefore, in order to prevent overheating of building elements and excessive energy consumption, it is necessary to correctly calculate the power of the system.

In a self-regulating cable, the current-carrying cores are surrounded by a special conductive plastic, which, in fact, generates heat. The conductivity of the plastic fluctuates with temperature, which allows it to self-regulate the heat output of the cable system. Due to this, with a decrease in temperature, the cable will emit more heat, and with an increase, respectively, less.

Advice!

Thus, this cable system is more economical in terms of financial costs for electricity.

Technology of installation of icing systems

Stages of installation of anti-icing systems

The installation of a wired heating system for the roof and drain is mounted in the following sequence:

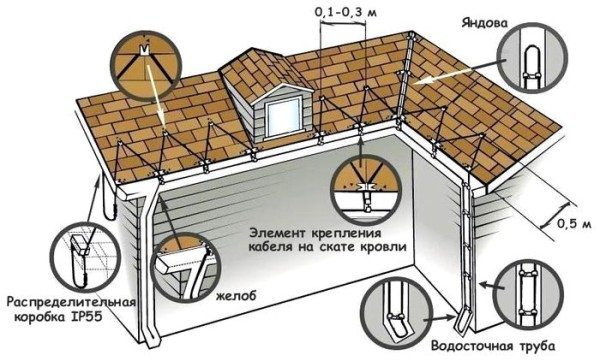

- Determine the cable laying area - in gutters, drain funnels, roofs, etc.

- Choose a method of laying wires, based on the characteristics of the roof.

- Determine the type of system control.

- The number of components of the anti-icing system is calculated and prepared.

- Install heating sections.

- Install junction boxes.

- Determine the electrical requirements for the system (in fact, its energy consumption) and select the appropriate wiring equipment.

- Arrange the system control cabinet.

- Mount power cables that provide power to the heating sections.

- Install temperature sensors.

- Perform a trial run of the system and its testing.

Features of the installation of the heating cable

Installation of anti-icing systems involves various methods of laying the heating cable. Their choice depends on the type of roof, in particular its temperature regime, the presence of gutters, etc.

As a rule, the method is chosen, guided precisely by the temperature regime:

- cold roof. These are called roofs, the premises under which are not heated during the cold period (a cold ventilated attic). Frost on this type of roof is formed when the air temperature rises to about zero.

In these cases, the power of the anti-icing system is chosen to be minimal, and its installation is sufficient only in part of the drain. - "Warm" roof. TO warm roofs include heated mansard roofs, which in winter at slightly negative temperatures provoke snow melting on the roof. Melt water on such roofs flows down to the cold roof cornice and drain, where it freezes, forming icicles.

For such a case, a snowmelt and anti-icing system installed in a complex is more suitable - on the eaves, gutters of the drainage system and other problem areas.

A properly selected method of laying an anti-icing system will allow you to get rid of icicles and frost at the lowest cost, regardless of the amount of precipitation and temperature outside the window. Almost every company-seller will be able to help with the calculation of the power of the system and the amount of necessary consumables.

Did the article help you?