Roofing from soft tiles is possible in cases where the slope of the slope is at least 12 degrees (1:5). A roof made of soft bituminous tiles is very attractive and easy to install even with relatively complex forms of roof structures.

Roofing from soft tiles is possible in cases where the slope of the slope is at least 12 degrees (1:5). A roof made of soft bituminous tiles is very attractive and easy to install even with relatively complex forms of roof structures.

The best time for installation of a soft roof is summer, since the sun's rays, gradually melting the self-adhesive layer of the coating, allow the tiles (shingles) to be reliably glued to the base, as well as to the tiles of adjacent rows.In this case, a high impermeability of the coating is achieved.

Preparation of the base for a soft roof

Soft tile roofing start by preparing the foundation. The material for this type of base, as a rule, is a material that has a continuous even surface and provides the possibility of fastening with nails.

Moisture resistant plywood, OSB sheets or edged tongue and groove board can be used here. In any case, the moisture content of the material used must not exceed 20% of its dry weight. At the place of the supports, the joints of the boards are located, and the length of the boards must be at least 2 x spans between the supports.

The expansion of boards under the influence of fluctuations in temperature and humidity should also be taken into account, leaving a sufficient gap between the boards, otherwise the roof of soft tiles may be deformed and lose tightness.

Ventilation gap device

The ventilation gap usually has considerable dimensions - at least 50 mm. Have an exhaust hole on a structure such as rolled standard roofing, as high as possible, the air inflow holes are arranged, respectively, in the lower roofing part.

What are the functions of ventilation?

- removal of moisture from the roofing material, lathing and insulation;

- reducing the formation of icicles and ice on the roof in winter;

- decrease in temperature in the interior of the structure in summer.

Proper roof ventilation is the key to a long roof life.

Underlay installation

A reinforcing underlayment is generally understood to mean the installation of rolled roofing insulation material over the entire roofing area.

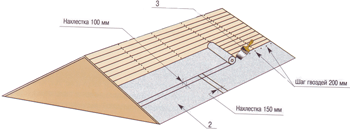

The lining layer is mounted parallel to the eaves of the roof in the direction from the bottom up and with an overlap of 10 cm or more. The edges are fastened with nails at intervals of 20 cm, and the seams are sealed with glue.

When the slope of the roof slope soft roof more than 18 degrees, lining material can only be laid on roofing ridges, end parts, eaves and valleys, as well as in places of passage through the roof (chimney and ventilation pipes, vertical walls, etc.).

Depending on the method of fixing the drainage system, it may be necessary to install brackets for mounting the underlayment.

Installation of metal eaves, pediment strips and valley carpet

Rules for the installation of the above elements of the roof structure:

- To provide protection on the cornice overhangs, the edges of the lathing from rainwater are mounted on top of the lining carpet, the so-called droppers (metal cornice strips) with an overlap of at least 2 cm. The strips are nailed in a zigzag manner using roofing nails in 100 mm increments.

- To ensure the protection of the edges of the lathing on the end roofing parts, gable strips are mounted with an overlap of at least 2 cm. They are nailed in the same way as the cornice strips.

- To improve the waterproofing properties in valleys, a valley carpet is laid over the lining layer in accordance with the color of the shingles. Fix the edges with roofing nails every 100 mm.

Installation of cornice and ordinary tiles

Next, proceed to the installation along the cornice overhang of the cornice tiles. At the same time, a protective film is previously removed from its lower surface.

The cornice tiles are laid end-to-end, stepping back from the place of the inflection of the plank up 10-20 mm. Eaves tiles are nailed near the place of perforation with further overlapping of the fasteners of ordinary tiles.

Advice! Installation of ordinary tiles starts from the center of the cornice overhang and is carried out towards the end elements of the roof.

The tile is glued, removing a preliminary protective film from it. With a roof slope of 12-45 degrees, fastening is carried out with 4 nails, over 45 degrees - with 6. Fastening is carried out along the edges and just above the groove of the shingle, with a slope of more than 45 degrees, 2 nails are additionally fixed at the upper edges of the shingle.

The technology of roofing from soft tiles is approximately as follows:

- The first row of tiles is laid in such a way that its lower edge is located no higher than 10 mm relative to the lower end of the cornice tile, and the petals cover the joints of the cornice tile.

- Further rows are mounted, ensuring that the ends of the petals are located above or at the same level relative to the cutouts of the tiles of the previous row.

- At the ends of the roof, the tiles are usually cut along the edge, after which they are glued with a 10 cm strip of glue.

- In the valleys, the tiles are cut so that open strips about 15 cm wide remain at their bottom.

- The edges of the tiles are glued with K-36 glue along the cutting line to a width of at least 10 cm. Plywood is placed under the tiles when cutting to prevent damage to the lower layer of the roof carpet.

Installation of ridge tiles

Tiles of this type are obtained by dividing cornice tiles into 3 parts according to the places of perforation.

Installation is carried out as follows:

- Remove the protective film from the roofing material.

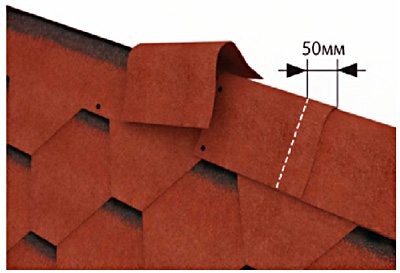

- Ridge tiles are mounted on the roofing ridge with the short side parallel to the ridge.

- Nail the shingle with 4 nails so that they are under the next tile, applied with an overlap of 5 cm.

Installation of flexible tiles at the junctions

Passages through the roof of small diameter are performed using rubber seals. Chimneys and pipes of other types that are subject to heat must be insulated.

The installation of flexible tiles in close proximity to pipes and other penetrations requires installation along the entire perimeter of the vertical element at the point of its connection with the roof of the triangular rail with a cross section of 50 * 50 mm.

Then, a lining carpet is mounted around the element, and the overlaps are smeared with K-36 glue, after which the roofing tiles are placed on a vertical surface and glued.

The lining carpet is glued in such a way that it steps on the pipe by more than 30 cm, and on the roof slope - by more than 20 cm. The junction is closed with a metal apron fixed mechanically.

Next, the seams are sealed with silicone sealant, which is quite resistant to atmospheric phenomena. The adjoining of the roof to the vertical walls is performed in a similar way.

How to use K-36 sealing adhesive

This adhesive is used to seal the following types of nodes:

- overlaps on the valley carpet of ordinary tiles;

- places where the roof adjoins the vertical element (driving);

- overlaps of the lining carpet itself.

Depending on the type of application site, the consumption of K-36 glue is 0.1-0.7 liters per linear meter.

Apply glue according to the following rules:

- Clean the place of application from oil, dirt, loose materials.

- On dusty and porous bases, a bituminous solution is first applied.

- Glue is applied to one of the surfaces to be joined using a spatula with a layer of 0.5-1 mm thick.

- The gluing width is determined according to the installation instructions.

- When pasting joints to pipes or walls, glue is applied over the entire contact area.

- The seams of the brickwork are rubbed with mortar at the level of the brick. Bonding occurs within 1-3 minutes after applying the adhesive, depending on the ambient temperature.

At low temperatures, the installation of a soft roof may require the adhesive to be heated.

Advice! Before gluing on a primed surface, make sure that the primer is completely dry.

The glue should be stored at temperatures up to +30 degrees, apply - in the temperature range of +5..+50 degrees. Complete drying of the adhesive, depending on the ambient temperature and the thickness of the adhesive layer, takes from 1 to 14 days.

Did the article help you?