The upper element of the structure - the roof, is a barrier that protects the roof and the building as a whole from the influence of atmospheric precipitation. Whether the roof will be durable and strong depends on the coating from which it is made. The second indicator that ensures the long-term operation of the roof is the technology of roofing, which will be discussed in our article.

The upper element of the structure - the roof, is a barrier that protects the roof and the building as a whole from the influence of atmospheric precipitation. Whether the roof will be durable and strong depends on the coating from which it is made. The second indicator that ensures the long-term operation of the roof is the technology of roofing, which will be discussed in our article.

Technological stages

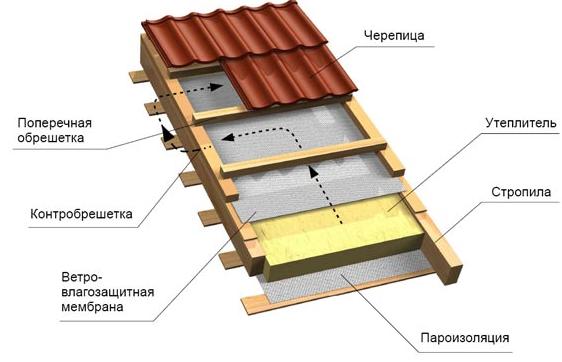

The roof structure includes the following elements:

- ventilation;

- insulation;

- waterproofing;

- vapor barrier.

When carrying out roofing work, it is important that all elements are included in the design.

Incorrect installation of one part that makes up the roofing, or its exclusion, leads to the fact that the roof passes moisture or cold. And this, in turn, reduces the reliability of the roof and its function to protect the house from atmospheric phenomena.

In order for the roofing to retain its properties and perform its functions over the course of long-term operation, it is necessary to carry out work on the installation of the roof in compliance with the technological processes determined by a certain roofing and the technology of its installation on the roof.

The technology for performing roofing work during the construction of the roof and the installation of the coating includes the following steps:

- installation of the truss system;

- vapor barrier device;

- laying of thermal insulation (insulation materials);

- installation of a waterproofing layer;

- installation of the lathing (the design of the lathing depends on the type of roof and the type of roofing, for example, when arranging a roof with flexible tiles, moisture-resistant plywood in the form of a solid base serves as the lathing);

- installation of a counter-lattice;

- laying roofing material;

- arrangement of roofing elements (cornice, ridge and others);

- equipment in the roof space of the ventilation system;

- installation of elements for movement on the roof;

- finishing of the cornice overhang;

- arrangement of elements of the drainage system.

Advice. As you can see, the roofing technology consists of many stages that make up the complex of works on the roof. Deviation from the technical standards for the implementation of a certain stage threatens with serious violations and the need for their quick correction.Therefore, treat the roofing device with seriousness and a professional approach.

Roll roof technology

The reliability of the roll coating depends on the technology of its laying, which, first of all, is based on the preparation of the base for the roofing.

There are several options here:

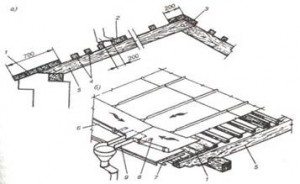

- the device of a dense crate with a coating of its surface with construction paper in several layers;

- the device of a rare crate with a flooring of asbestos sheets 5 mm thick.

In any case, the base must be solid and even, on which a roll coating (roofing material) is subsequently glued.

For gluing roofing material is used:

- cold mastic;

- molten bitumen (hot mastic).

For the bottom layer, roofing material with fine-grained dressing is used. Laying is carried out from below, parallel to the ridge. For the top layer, material with a scaly or coarse-grained dressing is taken. The direction of laying depends on the angle of inclination of the slope:

- on flat roofs with a slope angle of less than 15 degrees - parallel to the ridge;

- on slopes exceeding 15 degrees - perpendicular.

The technology of laying rolled materials is carried out in compliance with the following rules:

- layer mastics for the roof is 2 mm;

- the overlap of the strips is 10 cm or more;

- an additional layer of roofing material is laid on top of the ridge - with a descent of 50 cm onto the roof slopes;

- each layer of roll coating is pressed.

Attention. This technology of laying rolled materials is applicable in the arrangement of mansard, shed, gable roofs. Rolled carpet on tented, hip and roofs is usually not used.

Roofing equipment

The work of a roofer depends not only on what technology he uses, but also on what tool he uses for roofing.

At present, to facilitate the performance of work on the roof, all known, traditional tools are being replaced by more convenient and technologically advanced construction tools. This in its measure is reflected in the quality of the roof and its appearance.

The main thing that a roofer should have is various hammers for working with sheet metal.

They are used for forming fasteners on metal sheets, as well as for dredging and driving nails. Roofing hammers in the process of impact suppress vibrations as much as possible.

When performing work on the roof, it is necessary to use short, long, straight and curved tongs. They serve:

- for forming bends on sheet metal;

- tile processing;

- bending gutters.

For better work with roofing materials, various types of scissors are used:

- for normal and continuous cutting;

- universal;

- for cutting radii;

- left and right;

- curved and straight cut.

Scissors are used when working with galvanized steel, aluminum, copper, zinc and titanium.

During the work on the arrangement of the roof, all kinds of measuring tools will also come in handy: tape measure, ruler, thickness gauge, folding ruler, square, compasses, center punch and others.

The main thing that a roofer should have is a tool belt with all kinds of compartments. This greatly simplifies the work at height.

Advice. It is not necessary to buy all roofing tools before starting work on the roof, many of them can be borrowed from friends or rented from specialized companies.

Metal roofing technology

Having a set of tools, you can easily perform a metal roofing technology, the widespread use of which is due to such factors:

- durability;

- easy care;

- light weight;

- savings on materials for roof construction.

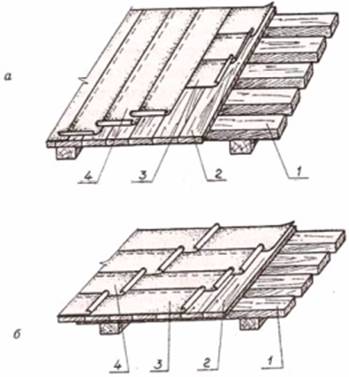

For the crate under the metal coating, bars of 50x50 mm are taken, a board is laid on the cornice and along the ridge. To ensure internal ventilation of the roof, the pitch of the lathing is at least 250 mm. This prevents the formation of corrosion and increase the life of the roof.

When using sheet steel, sheets are cut, patterns are formed and folds are created. When using other metal coatings, a preliminary measurement is carried out, immediately before the stage of their fixing occurs.

Roofing from a metal tile or corrugated board are overlapped, in order to avoid moisture getting under the coating, it is fixed in the deflection of the wave with threaded nails and a rubber gasket.

When arranging sheet steel, the connection of paintings on roofs with a slope angle of more than 16 degrees is carried out with a single fold; with a small slope - double.

Pictures connected by a recumbent fold are located parallel to the ridge, standing - along the slope. When the roof surface is completely covered, a ridge is bent on the roof ridge.

Attention.The device of a metal roof requires the closest possible calculation of the material and patterns in order to avoid its incomplete fit and the creation of risk zones on the roof in relation to the flow of moisture.

Equipping equipment

When creating a metal roof, roll or other type, a roofer will need roofing equipment. It has the same meaning as a tool set for a performer of construction and repair, technological operations.

When arranging the roof, the presence of equipment helps to save time and effort.

It includes various types of electrical tools:

- electric saw, electric planer (for mounting the truss system and battens);

- electric drill (for screwing fasteners).

With a design such as seam roof Of great importance is the presence of a rolling machine, which allows you to make paintings along the entire length of the slope, with the exception of horizontal joints.

Very often, for the installation or repair of the roof, gas burners are used to heat the materials and the surface of the roof in winter, or to lay a hot mastic coating on the roof.

Gas burners provide heating of the material (for example, bituminous mastic) until it reaches the required process temperature.

In multi-storey construction, a roof crane is used to lift wooden, metal elements of the roof structure and roofing.

For production equipment that is used for roofing, requirements are put forward that meet the provisions of GOST (12.2.003-74.).

Eg:

- installations for melting bitumen must be equipped with thermometers and a pipe that discharges the combustion product:

- equipment for drying the base under the built-up coating must have a protective screen;

- the fuel tanks of the equipment must be refueled by mechanized means.

Types of equipment are selected depending on the working conditions and the type of roof. It could be:

- ice rink;

- machines for rolling rolls, cutting the roofing, leveling the roofing layer, perforating the old roofing;

- units for applying a primer or paint layer.

The high quality of materials, inventory, equipment for roofing, as well as the professionalism of roofers, together lead to the creation of a reliable roof with a guarantee of a long service life.

Did the article help you?