Profiled sheet is a new inexpensive, environmentally friendly and aesthetic material that has recently become widespread and is used in the construction of a variety of objects (both country houses and roofs, fences, fences, etc.). This article tells about how the house is sheathed with corrugated board, how to choose the right material and tools, and what nuances should be taken into account.

Profiled sheet is a new inexpensive, environmentally friendly and aesthetic material that has recently become widespread and is used in the construction of a variety of objects (both country houses and roofs, fences, fences, etc.). This article tells about how the house is sheathed with corrugated board, how to choose the right material and tools, and what nuances should be taken into account.

During the construction of various buildings and structures, the decoration of their facades plays an important role. In the middle of the twentieth century, new technologies appeared in this area of the construction industry, which include hinged ventilated facades.

Currently, attention is paid not only to the external appearance of the building, but also to the improvement of all its performance indicators, and therefore reducing the energy intensity of systems was one of the research priorities.

The technology of creating ventilated facades has brought the construction industry to a new level due to its high functional and aesthetic parameters, which are of great importance for installers, as well as for designers and architects.

Hinged facades can be used not only in the construction of new buildings, but also in the reconstruction of old facades, changing their appearance and improving the quality of thermal insulation.

In our country, ventilated facades have been used since the 90s of the 20th century, and houses sheathed with corrugated board are now widespread everywhere due to the economy and attractiveness of this method.

A house sheathed with corrugated board can be both residential and industrial, administrative or public building.

For this type of sheathing, there are many different design solutions, with minimal maintenance costs. Properly and tastefully chosen cladding can make the building unique in terms of appearance.

Sheathing with corrugated board is used everywhere in our time, they are sheathed with walls of such buildings and structures as:

- Sheds;

- Garages;

- Hangars;

- Industrial premises;

- Residential buildings, etc.

For example, sheathing a wooden house with corrugated board is not only a fairly inexpensive procedure, but also quite simple in terms of installation.

At the same time, the requirements for cladding with corrugated board are not as strict as for cladding, for example, with natural stone, which allows you to sheathe the house yourself.

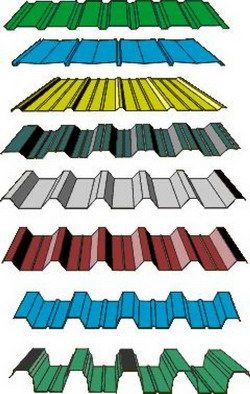

The choice of wall corrugated board for house cladding

To understand how to sheathe a house with corrugated board, you should understand the designations used when marking the material. First of all, it should be noted that the letter "C" in the marking means wall corrugated board.

Let's give an example of a complete decoding of the name C8 1150.0.6: this marking means wall decking, whose corrugation height is 8 mm, the width is 1150 mm, and the thickness is 0.6 mm.

Facing a house with corrugated board is most often performed using corrugated board of the following brands:

- C8;

- C21;

- C44.

At the same time, it is very important to carefully measure all the structural elements of the house, and it is recommended to take measurements twice in order to avoid various errors and inaccuracies that most often occur when measuring the distances between windows, etc.

Sheathing a wooden house with corrugated board can be performed both in the horizontal direction and in the vertical direction. You must first choose the direction of the skin, and only then acquire the material.

When performing cladding, it is also important to leave an air gap provided by the material technology itself. This layer provides free circulation of outside air between the insulation and sheets of corrugated board and prevents the accumulation of water vapor, removing them to the outside.

As a result, there is no development of various microorganisms, molds and fungi that cause gradual destruction of the walls.

Sheathing with a corrugated board of a wooden house will be incomplete without sheathing of various additional elements, such as window framing and door frames.

There are the following additional elements:

- basement;

- roofing ridge;

- corner;

- gutter

- elements that cover the gaps between the sheets that have arisen during the installation process;

- in the presence of a Russian stove or fireplace, special additional elements used in framing pipes will also be required.

With help additional elements of the roof, also made of galvanized steel, various design solutions can be implemented, and the element can be painted in any desired color.

Facing the house with corrugated board

Proper execution of facade cladding with corrugated board helps prevent external factors from affecting the wall, and the air gap provides ventilation and ventilation, preventing the appearance of mold, condensation, etc.

In addition, this layer acts as a heat and sound insulator.

Thanks to this, a balcony sheathed with corrugated board can be turned into a full-fledged living space, in which it is warm in winter and cool in summer. The correct organization of the air layer ensures the safety from the inside of both the wall and the corrugated board itself.

Important: the air gap should be made so that the air in it constantly circulates without stagnation.

Cladding a house with corrugated board can be done in two ways: mounting sheets on a pre-built wall, or cladding prefabricated wall elements.

In order to sheathe the house with corrugated board, you must perform the following sequence of work:

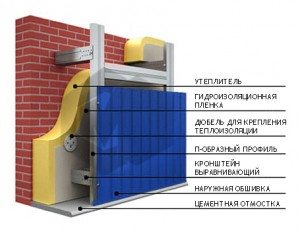

- A metal frame is mounted on the wall, made of mounting brackets with reinforcement. The frame is geometrically correctly aligned using levels and attached to the wall with dowels. Wood (slats) can also be used to make the frame, but the most preferred option is to make a metal frame. It is possible to sheathe walls with corrugated board both by placing the sheets vertically, and by performing their horizontal orientation. There are even specific design solutions that provide for diagonal orientation of sheets. Regardless of which sheet orientation is chosen for the sheathing, performance remains the same.

- If necessary, a layer of insulation is laid, which is covered with a film to protect it from moisture. Insulation fasteners are made using dish-shaped dowels.

- Sheets of corrugated board are fastened to the frame. For fastening, self-tapping screws made of galvanized steel are used, equipped with moisture-proof gaskets.

- The final stage is the installation of additional elements.

In the case of sheathing a prefabricated insulated panel with corrugated board, first of all, high-quality waterproofing of the building foundation should be performed using a roofing material laid in two layers:

- The guide profile is fixed on the foundation with anchors.

- Next, racks are vertically attached to the profile, equipped with a jumper on top, as a result of which a wall frame is obtained.

- Plates of thermal insulation material are placed in the cells of the resulting frame.

- On the sides of the frame, the strips are mounted, to which the sheets of corrugated board will be attached.

- Sheets are fixed in the same way as sheathing an ordinary wall, using self-tapping screws with sealing gaskets.

As you can see, wall cladding with corrugated board is not a particularly difficult job, but some points should be considered in more detail.

Sheathing the house with corrugated board should be done in such a way that an air ventilated layer forms between the surfaces of the insulation and the corrugated board.

It increases the duration of the life of the structure due to the circulation of outside air, which allows moisture vapor to be removed outside, preventing them from accumulating under the cladding.

In addition, corrugated sheathing provides the following advantages:

- Good sound insulation;

- High level roof insulation;

- Reliable protection of walls from external influences;

- The ability to implement unique design solutions.

The main nuances associated with corrugated sheathing

- Currently, attention is paid not only to the external appearance of the building, but also to the improvement of its various operational indicators. Ventilated facades have brought the construction industry to a new level of development, and the sheathing of houses with corrugated board has become quite common due to its reliability, quality and, at the same time, rather low cost.

- Cladding of a hinged facade made of corrugated board is perfect not only for residential buildings, but also for public, industrial and administrative buildings and structures. This type of cladding is characterized by a variety of architectural and design solutions, and maintenance costs are minimal. Properly chosen cladding of the facade of the building allows you to emphasize its individuality and uniqueness.

- When performing sheathing with corrugated board, it is imperative to leave an air gap for ventilation. This allows you to significantly increase the life of the facade structure. Air circulation in the system will allow moisture vapor to be released outside, preventing them from accumulating under the cladding layer, as well as preventing the development of harmful microorganisms and mold, which gradually destroy the walls. In addition, this type of sheathing has high rates of heat and sound insulation.

Profiled sheeting is a modern and at the same time quite economical way of manufacturing a hinged facade.

New forms of profiled sheet are constantly appearing in the assortment, which can be placed both horizontally or vertically, and diagonally.

In addition, the material is equipped with a modern polymer coating and is equipped with corner elements, which together allows you to give the facade its own unique style.

In addition, due to the low weight of corrugated board, its installation can be carried out on horizontal and vertical lightweight structures, and the ease of installation allows you to do the sheathing yourself, even without special training and qualifications.

Did the article help you?