Decking has recently gained great popularity in the construction of both residential buildings and various industrial and utility buildings and structures, as well as various fences. Installation instructions for corrugated board will help you figure out how to properly cover surfaces with this material so that it serves for a long time and reliably.

Decking has recently gained great popularity in the construction of both residential buildings and various industrial and utility buildings and structures, as well as various fences. Installation instructions for corrugated board will help you figure out how to properly cover surfaces with this material so that it serves for a long time and reliably.

Roof decking is produced in the form of trapezoidal wall and roof profiles, the depth of which can be 10, 20, 45 or 57 millimeters. The length of the profile is made individually in accordance with the requirements of the customer.

For the production of sheets, galvanized steel with a thickness of 0.45 and 0.7 mm, or galvanized steel with a polymer coating, the thickness of which is 0.5 mm, is used.

The main application of corrugated board is to cover the arrangement of building elements such as roofs and ventilated facades.

This manual describes the process of installing corrugated board on the roof, and installation instructions for wall corrugated board will be given in another article.

Installation of corrugated roofing

Since the type of work that this instruction considers - installation - the corrugated board in this regard resembles a metal tile, the installation process of which is also quite simple and includes the same basic steps.

However, there are a number of differences that need to be pointed out.

Since the material for which the installation is described is corrugated board, the instruction recommends working on the roof, the slope of which should not be less than eight degrees. When installing such a roof, special attention should be paid to such elements as high-quality efficient ventilation and sufficient sealing of through joints and leads.

At roof covering for more sloping forms, special design solutions apply, for consultation on which you should contact the manufacturer.

First, they perform as a base for the roof - as the corrugated board instructions prescribe - the installation of a crate from antiseptic-treated boards or steel girders (in this case, the height of the corrugation should be at least 4 cm).

Roofing from corrugated board is recommended for arrangement in those buildings, the length of the slopes of which does not exceed 12 meters.

In the case of laying several sheets on a slope, a horizontal overlap should be made, depending on the angle of the roof slope:

- At roof slope no more than 14 degrees overlap is over 200 millimeters;

- At an inclination from 15 to 30 ° - 150-200 millimeters;

- If the angle of inclination is more than 30 degrees, the horizontal overlap should be from 100 to 150 millimeters.

Useful: if the roof slope is up to 12 degrees, the vertical and horizontal overlap is sealed with silicone or thiokol sealant.

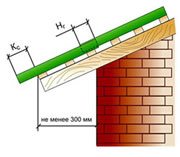

When performing corrugated boarding - installation instructions also prescribe to leave an overhang of the eaves, depending on the height of the sheet profile:

- For PK-8, PK-10 and PK-20, the overhang of the eaves is 50-100 mm;

- For the rest - from 200 to 300 millimeters.

The operation of the house is always accompanied by the release of moisture from the interior and its condensation in the under-roof space. In order to prevent its accumulation and condensation under the roof, the roof must be built in such a way that the temperatures of the air outside and in the under-roof space coincide.

This is achieved by arranging the following elements of the roof structure:

- Carefully executed thermal insulation;

- Effective ventilation;

- Installation of a layer of vapor barrier material.

It is also important to ensure that the air flow from the eaves under the roof ridge can freely rise, and the ventilation holes are located at its highest point.

The following elements are used to remove air:

- Ventilation grilles at the ends of the building;

- The gaps between the roofing slabs and the ridge bar;

- Additional ventilation channels for difficult-to-ventilate structures.

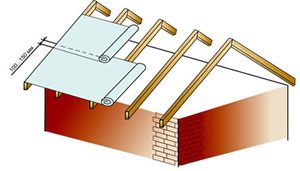

The waterproofing film is laid horizontally, in the direction from the eaves towards the ridge.

At the same time, an overlap should be left (from 100 to 150 millimeters) and the film should be allowed to sag approximately 20 mm between the rafters. After the film is laid, it should be hermetically overlapped, and the joints should be glued with adhesive tape.

The ventilation efficiency of the space under the roof is increased due to the gap between the crate and the film, which is 40-50 millimeters.

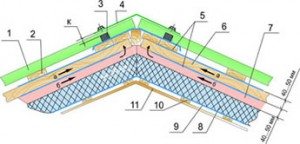

1 sheet of corrugated board;

2-Crate;

3-ridge seal;

4-horse;

5-Film waterproofing;

6-Plank rafters;

7-Leg rafters;

8-Insulation material;

9-Vapour barrier film;

10-ceiling rail;

11-Clapboard or drywall

In order for air to pass freely through the ridge, the waterproofing film should be laid so that it does not reach it by 40-50 mm, and a gap between the ridge seal and the ridge itself (k) should be provided.

Galvanized self-tapping screws with a sealing washer are used to fasten a sheet of corrugated board to a purlin or crate. Fastening is carried out at the bottom of each wave, and each next sheet should cover the previous one. Longitudinal joints are also fixed with self-tapping screws.

It is recommended to fasten the corrugated board to the crate in the lower parts of the corrugations, using 5-7 self-tapping screws 4.8x28 ... 40 per 1 m2 coatings. The fastening of the ridge is carried out in the upper corrugation, selecting the length of the self-tapping screw in accordance with the height of the profile.

Next, consider such elements as the overlap of the corrugated board and its gable cut. The size of the side overlap is usually half the wavelength of the profile, and in the case of roofs with a slope of less than 10 degrees, a wider overlap is recommended.

The size of the top overlap also depends on the slope of the roof:

- 10 centimeters with a slope exceeding 10 degrees;

- 20-25 cm at a slope below 10°.

The plates are built up over the laths, while the overlap, if the corrugated board is installed on the walls, is 100 mm, and on the roofs - 200 mm.

In the case of flat roofs, it is also recommended to use mastic or a special sealing tape.

The extension point is attached to the crate with screws in the places of deflections of each wave. When laying such profiles as PK-20, PK-45 and PK-57, installation should begin from the end of the roof.

Important: in case of using roof slabs equipped with a drain groove, the laying must be carried out in such a way that the groove of the laid sheet overlaps with the next one, and the slabs must be laid perpendicularly.

The "wind" bar is fixed with self-tapping screws with a pitch of 200-300 mm. The transverse overlap between the planks should be 100-150 mm.

Making the junction of the slopes to the wall:

- With the longitudinal junction of the slopes, the corner plank is fixed so that the pitch is 200-300 mm, and the overlap of the planks is 100-150 mm.

- In the case of a transverse junction of the slopes, the corner strip is also fastened in increments of 200-300 mm, and the overlap is 150 mm.

Additional information about the installation of corrugated board

- Skate decoration. The K1, K2 or K3 bar can be used as a ridge. Profile seals are used to seal ridge battens in the case of hipped roofs. The installation of the ridge element begins on the side that is opposite to the prevailing rains and winds. The overlap during laying is 100-200 mm, and fastening is carried out using self-tapping screws screwed into the upper corrugation in increments of 200-300 mm.The length of the self-tapping screws used depends on the height of the material profile.

Useful: In the case of small angles of inclination of the roof, it is recommended to use a sealing gasket on the ridge to prevent water from getting under the ridge during slanting rain or strong winds. When installing such a gasket, you should also provide a gap between it and the ridge for ventilation.

- Snow guards installed next to the eaves prevent the snow cover from sliding and rolling over the front door, the road running along the house, etc. At the attachment points of the snow guards, additional reinforcement of the crests of the waves of the corrugated sheets should be performed. Fastening is carried out along the crest of every second wave above and below the snow stop.

- Cleaning of corrugated board. After processing, metal shavings should be carefully removed from the sheets of corrugated board. Conventional detergents can be used to clean contaminated sheet surfaces. Organic solvents are not recommended to avoid damage to the polymer coating.

- It is necessary to periodically clean the debris and leaves accumulating on the corrugated board in spring and autumn, and in the winter period - to clean off the snow cover, trying not to damage the coating of the sheets. The zinc coating protects the material from rust even if there are scratches on the surface of the sheets, but it is still recommended to paint over them with spray paint.

- In some cases, it may be necessary to process sheets before their installation. They are cut using tin shears, a hard-alloy electric saw or a fine-toothed hacksaw.

Important: in no case should you use an abrasive tool such as a "grinder" for cutting sheets: high temperature destroys the protective coatings of the corrugated board.

- Profiled sheeting with a protective coating can be stored for a month on a horizontal surface, if the original packaging is not broken. During storage, under the package, bars with a height of about 20 cm should be placed at intervals of 50 cm. In the case of a longer storage period, the sheets are shifted with slats. The shelf life of galvanized plates in packaging from the factory is no more than a week; to increase the shelf life, the material is also shifted with slats.

That's all I wanted to talk about how to mount the corrugated board - the installation instructions are designed to help solve various issues that may arise during the installation process, as well as ensure the highest quality do-it-yourself work.

The main purpose of the instructions is to ensure that the installed corrugated board has served reliably for many years without creating any problems or unpleasant situations.

Did the article help you?