Sheds of various designs and materials used are very common in suburban areas. They are used as outbuildings, garages, gazebos for relaxation, barbecues, etc. In this article, we will tell you how to build a canopy from a metal profile, which is the most popular building and cladding material for such structures.

Features of profiled metal

First of all, you need to figure out why the metal profile is so attractive.

Material advantages

- An important advantage of sheet and pipe products is strength and reliability.. Profiled pipes for the frame have walls of 3/4 mm, and sheets of corrugated flooring have a thickness of 0.5/0.8 mm. This is quite enough to build a structure resistant to all loads and impacts.

- The material has excellent wear resistance.

- The corrugated surface of the cladding and its upper polymer layer make the roof more attractive and durable.. You don't need to paint it.

- Among other things, rolled metal products are environmentally friendly and do not emit harmful substances and unpleasant odors..

- You can build such a structure with your own hands very quickly., even without good building skills.

Difficulties of work

- Despite the simplicity of the structure, the arrangement of the canopy is somewhat difficult. The main difficulty in this case is to carry out accurate design calculations, which to a large extent affect the reliability and durability of the structure.

- When making a canopy of a non-standard, polygonal, rounded shape, the main problem is to fit the pipes in size or bend them at the right angle. In domestic conditions, this requires special tools.

Attention!

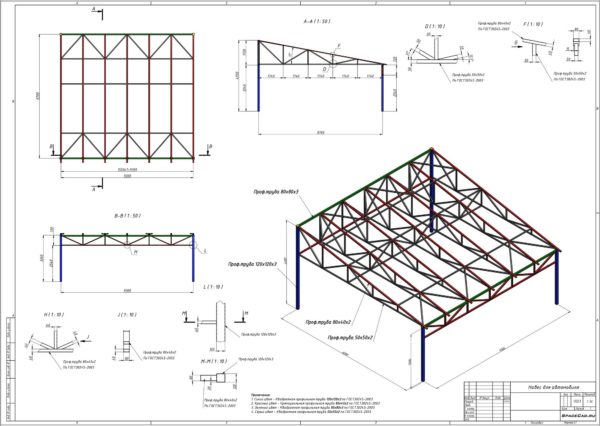

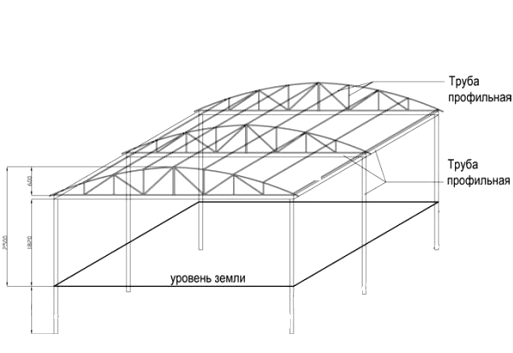

Before construction work, projects of sheds from metal profiles are made.

In the course of their creation, the dimensions of the building are determined (based on your needs and the resulting loads on the structure), its location, the shape of the structure and the type of roof. Next, drawings of the structure are drawn up.

What will be needed

- You will need roofing, in our case, these are sheets of profiled metal.

- For the supports of the structure, purchase profile pipes. Their cross section can be 100 × 100, 80 × 80 or 60 × 60 millimeters, based on the size of the canopy.

- As a strapping and material for a roof truss, you can choose profile pipes for a canopy with sides 60 × 40 or 60 × 60 millimeters.

- For roof lathing, products with a section of 40 × 20 or 20 × 20 millimeters are suitable.

- As fasteners, you will need galvanized self-tapping screws to match the color of the profiled sheets, anchor bolts and press washers for poles.

- To fix the supports, you will need general construction concrete, for floors under a canopy - concrete, ceramic tiles or the same concrete mortar.

Canopy construction

Now directly about how to make a canopy of profiled metal yourself.

Preparatory work and installation of the frame

First of all, it is necessary to prepare the place chosen for the construction of the canopy.

- Clear the site of plants, grass, foreign objects, debris.

- Level the place. Next, mark up the future structure.

After that, you can begin the installation of pillars, which will be the supports of the structure. For this, drawings of canopies from a metal profile are used.

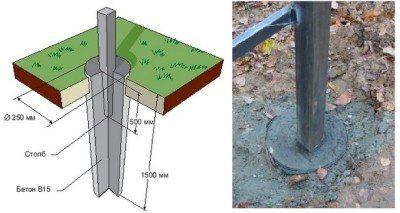

- The gaps between the posts should be about 1 meter. You need to install them around the entire perimeter of the building. First of all, it is necessary to dig holes for pipes of the selected section, then put them in the pits and pour concrete.

Note!

The depth of the holes depends on the type of soil in your area and the level of its winter freezing.

Be sure to control the position of the supports using the building level.

- Next, mount the strapping lags. They must be fastened by welding to the supporting pillars. If the structure is small, you can use bolt fasteners. Then installation will be easier, and its price will decrease.

- Then you can start installing the supporting arch. Such a design will further enhance the strength of the structure and give it an external appeal. You can mount several arches. Support they must have runs and racks.

- When the main frame is ready, the roof crate should be made, it will serve as a support for the corrugated board. It needs shaped pipes having a length greater than the gap between the last and first arches by 20/30 cm. In other words, the roof should protrude slightly beyond the frame. So the interior of the canopy will be better protected from rain.

Note!

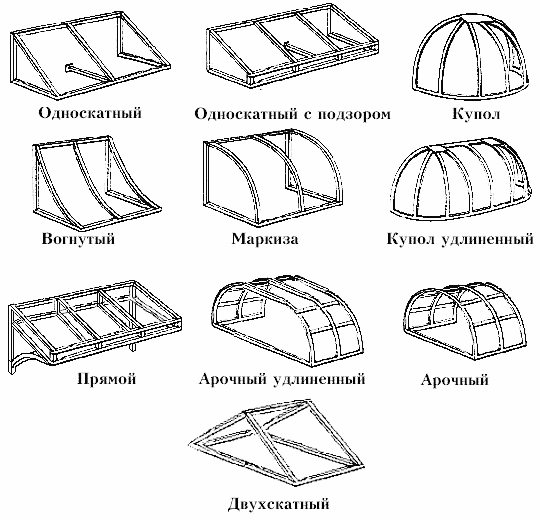

Types of canopies from a metal profile are not limited to arched counterparts.

They can be ordinary rectangular, with a single or gable roof.

For a car, a small building with the simplest roof.

For household needs, you can install a gable design.

Installation of corrugated board

- Fix all profiled sheets to the transverse pipes of the crate with self-tapping screws with special rubber gaskets. So you protect the metal from damage.

The cut areas of the flooring should be treated with a primer and coated with moisture-resistant paint. This will protect the sheets from corrosion. It is possible to choose fasteners to match the color of the decorative top layer of the material. - All frame elements: support pipes, strapping, rafters, battens, as well as welding and fastening points should also be coated with anti-corrosion primer, and then with weather-resistant paint.

- The instruction warns that roofing sheets must be mounted only with an overlap. They should be fixed with self-tapping screws exclusively along the upper ridges of the “wave”.

- If the structure will have a small area, there is no need to supplement the frame of the crate with reinforcing ribs, a skeleton with a step of 1 meter will suffice. And this coating will last a long time.

Conclusion

It is relatively simple to build a canopy from profiled rolled metal on your own. You will not need special knowledge and hiring specialists for this. The building will be strong, durable and relatively inexpensive.

Watch the video in this article. It contains a lot of interesting and useful information.

Did the article help you?