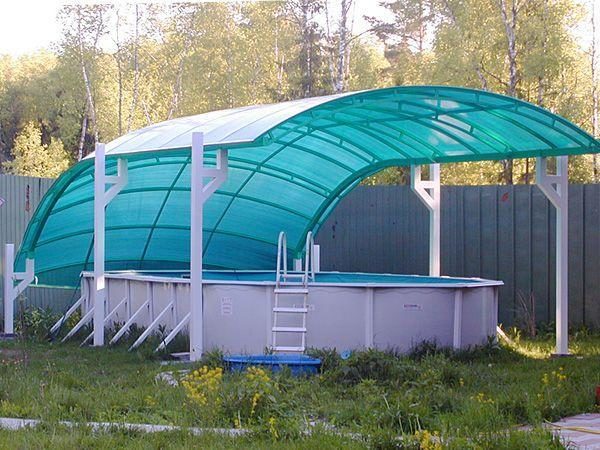

Every year, the number of artificial bathing places in suburban and household plots is becoming more and more. But at the same time, many problems arise: dust and falling leaves pollute the water, in the summer months the sun heats the structure too much, and much more. You can get rid of trouble by building a pool shed with your own hands, because the design is very simple, and the implementation of the project will not cause much difficulty for most people.

Advantages of canopies for swimming pools

If you are still thinking about whether you need a canopy over the pool, then it is important to understand what advantages the installation of the structure gives:

| Protection | Your pool will be protected from fallen leaves, debris and wind-blown dust. In addition, precipitation will not fall into it. This is especially important in winter, when it snows and there is a high probability of glaciation, which can destroy the walls. |

| Creation of comfortable conditions | The scorching sun in the summer is not the best option, so you need to close the pool from its effects. In addition, you can make a solid structure - and you will not be bothered by the wind. Also, you will be hidden from the eyes of strangers, which is important when you are near roads. |

| Improved aesthetic appearance | You can erect canopies for an artificial reservoir of various shapes and sizes, which will carry not only a practical function, but will also become a real decoration of your site. |

Important!

It is best to use impact-resistant cellular polycarbonate as a roofing material.

This is a very reliable material that does not prevent the penetration of light, but scatters it and does not transmit ultraviolet rays.

Features of the work

The simplest and most rational solution today are polycarbonate pool sheds. This is due to many positive qualities that simplify the work, while the price of the material is very affordable. Consider how to make a design yourself.

Preparatory stage

At this stage, the following work is carried out:

- A project is selected that should match exactly your pool and its size. You can make a plan yourself or find a ready-made solution on the Internet. It is very important that the project takes into account all the features of the future construction, since the alteration often causes more difficulties than the initial work.

- Next, you need to calculate all the required materials. For this, it is important that a detailed drawing with all dimensions and other necessary data is at hand.

- To assemble the structure, it is best to use a profile square or rectangular tube for a canopy. The option using wood is not suitable, since constant exposure to moisture will very quickly destroy the material, even if it is impregnated with protective compounds.

Important!

If you still decide to use a tree, then you need to opt for rocks that are resistant to moisture.

Larch is best suited, as it has a structure that does not absorb water.

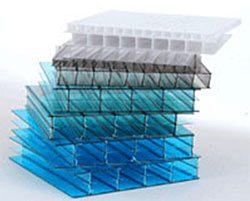

- The main roofing material is polycarbonate, it can be both transparent and with different colors. It is important to choose the best option, since each color gives its own shade, as practice shows, the most popular are transparent and blue polycarbonate. Thickness is also of great importance: the thicker the material, the stronger and more resistant it is to deformation.

- It is very important to choose strong and durable fasteners. The ideal option is special self-tapping screws with a washer, on the bottom of which there is a layer of rubber. Thanks to this, the holes are reliably protected, and the likelihood of deformation during fastening is much less.

Installation work

First you need to decide on the type of structure, if it is mobile, then the lower frame is welded first. If the system is stationary, then the main racks are first concreted, which must have sufficient bearing capacity.

The work is carried out taking into account the following recommendations:

- The structure is held together either by electric welding or by drilling holes and using bolts (stainless steel is best).

- First of all, the frame is assembled, after which its strength is checked, if necessary, reinforcing jumpers are additionally installed. It is very important that the system has no backlash and is securely fastened at all points.

- Further, all elements are carefully painted, for this it is worth using a special paint with anti-corrosion additives. This will protect the metal from the harmful effects of moisture and improve the appearance of the entire structure. It is best to paint in two layers, and in preparation to prime all parts of the structure.

- The next step is the fastening of polycarbonate sheets, the easiest way to do this is with a screwdriver. Holes are pre-drilled in plastic and metal, which should be slightly smaller than the diameter of the self-tapping screw (if the fastener is 4.8 mm, then the drill should be 4.2 mm, if 5.5 mm, then 5.0 mm, and so on). It is important to correctly combine all the elements.

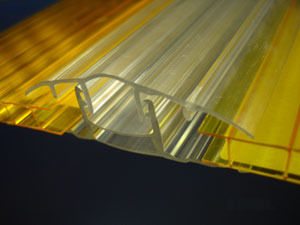

- For the best docking, it is best to use a special docking profile, an end plate is used to protect the ends, it prevents water and dirt from entering the polycarbonate cavity.

Conclusion

As you can see, the instructions for the work are simple, and almost anyone can handle the installation. The video in this article will clearly show some of the features of the workflow.

Do-it-yourself polycarbonate pool canopy does not require building qualifications, the material is very easy to work due to its flexibility and light weight.

Did the article help you?