How to make a canopy near the house, and what materials can be used to build the frame? What is the best way to cover it and how to protect the wall where it will be splashed with water from the appearance of fungus? Let's try to answer these questions.

frame

Let's start with making the frame. For its construction with your own hands, wood and a profile pipe can be used.

Reference: with the same cross-sectional area and wall thickness, a round pipe is more resistant to hydraulic pressure.But the profile (square or rectangular) is stronger for bending. For maximum rigidity, the larger side of the rectangular tube should be oriented parallel to the load vector.

Let's look at both cases in more detail.

Tree

What kind of wood is preferable to use?

- Oak, beech and ash combine the highest strength with a beautiful texture and rot resistance; however, their price is unlikely to please the economical buyer.

- Larch and cedar are an intermediate solution: they are also resistant to rot, strong enough, and much cheaper than noble wood.

- Finally, pine and spruce are a budget option that requires mandatory impregnation with an antiseptic and a protective water-repellent composition.

In order not to be unfounded, we give the average cost of different breeds per cubic meter.

| wood species | The cost of a cubic meter of timber 100x100, rubles |

| Pine | 6200 |

| Larch | 8000 |

| Cedar | 12000 |

| Oak | 30000 |

| Ash | 33000 |

Please note: prices in different regions of the country may differ significantly from the above. The table contains average values for the central regions of Russia.

What to look for when choosing lumber?

- Kiln-dried wood preferred. A tree of natural moisture, when dried, is likely to warp and crack.

- Knots and slant mean a sharp drop in the strength of the bearing elements.

Dimensions and sections

What should be the cross section of the pillars and beams of the canopy?

| Structural element | Size |

| pillars | 100x100 mm |

| Beams with a span of up to 3 meters | 100x40 mm |

| Beams with a span of up to 6 meters | 150x50 mm |

The step between the pillars is usually no more than 2 - 2.5 meters.

Technology

So, how to make a canopy to the house with your own hands?

Work begins with the installation of pillars.

- There are holes under them. With a round section, their diameter should be no more than 30 centimeters; depth - from 50 cm to a meter, depending on the type of soil. The less dense it has, the greater the depth.

Of course, a pit with such parameters cannot be dug with a shovel and a pickaxe. For this purpose, a garden drill is usually used.

Hint: as an option, you can dig a large hole and install a galvanized sheet rolled into a pipe with a diameter of 30 cm into it. Then the soil is poured around an impromptu pipe with a layer-by-layer rammer every 20 - 25 cm, after which the galvanizing is removed.

- Each hole is 10 cm filled with rubble.

- The underground part of each pillar is impregnated with an antiseptic, after which it is covered with bituminous mastic. Thus, we will prevent decay and protect the pillars from the attack of worms and woodworms.

- The column is installed in a pit along a plumb line, after which it is covered with rubble with constant control of the vertical position and layer-by-layer tamping.

- A securely fixed base of the column is poured with a liquid cement-sand mortar, prepared in a ratio of 1: 3.

After the mortar has firmly set (not earlier than after 3-4 days), the pillars are connected by a jumper - a beam of the same section. To connect the posts with the lintel, galvanized corner plates are used.

A board of the same size as the beams is anchored to the wall of the house. She, like the base of the pillars, is pre-impregnated with an antiseptic.Since bituminous mastic in this case will spoil the appearance of the canopy, it is better to use drying oil heated in a water bath as a hydrophobizing impregnation: it is applied in two steps without intermediate drying.

By the way: it is also better to impregnate the beams before assembling the frame. So corny more convenient; in addition, there is less chance that one of the ends will remain without impregnation.

The edge of the beams adjacent to the house is cut at an angle, ensuring their adjoining to the anchored board. Beams are laid edge on the jumper between the pillars; the second edge is attracted to the board drawn to the wall by the galvanized corners already familiar to us. To connect the beams with a jumper between the pillars, the same corners are used.

Proftruba

In this case, the frame is made all-welded, which ensures its maximum rigidity. What are the practical differences between a corrugated pipe frame and a wooden one in terms of construction?

- Each beam can be attached to the wall of the house independently of the others. To do this, a platform of 4 mm steel sheet with holes for the anchor is welded onto its end.

- For obvious reasons, an antiseptic is not needed, but the waterproofing of the underground part of the pillars is carried out with the same bituminous mastic.

- After welding is completed, the seams are cleaned of slag, after which the frame is prepared for painting - it is cleaned of rust residues with a metal brush (manual or made in the form of a nozzle for a drill or grinder). Painting is most often done with inexpensive and very resistant PF-115 alkyd enamel on GF-021 primer.

What should be the sections of the pillars and beams? A reasonable minimum pipe size for poles is 80x80 mm; beams with a span of up to 4 meters are made of a pipe 80x40. With a larger span, trusses are welded instead of beams from a straight pipe section.

Roof

Let's find out the better to block the resulting frame.

metal tile

With a service life of at least 30 years, it is highly resistant to impact and wind loads. Another advantage is a transverse wave, which prevents water from flowing even with a strong side wind and a small (less than 10 degrees) slope of the canopy roof.

Please note: The only serious drawback of metal tiles is noise in the rain.

How to attach sheets to the frame? They are laid with an overlap in one wave and are attracted by self-tapping screws with rubber press washers: for wood for a wooden frame, for metal for a welded one.

profiled sheet

A profiled sheet differs from a metal tile only in the absence of a transverse wave; hence the obvious instruction: with a slope of less than 10-12 degrees, you should not use it.

Overlap of sheets during laying - one wave for parallel sheets and at least 20 centimeters for stacked in series. Fastening to the frame - with the same screws as in the previous case.

Important: each wave is attracted by self-tapping screws. Large gaps will cause you to hear loud and unmusical sounds in windy conditions.

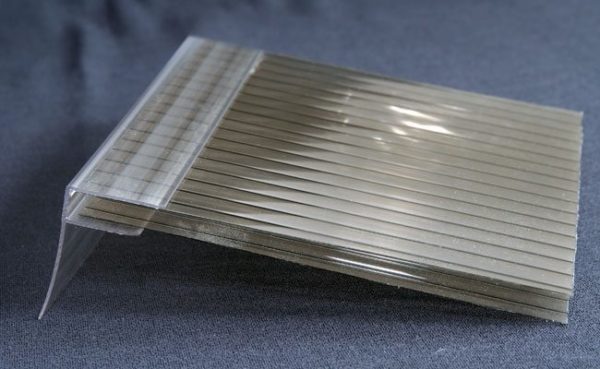

Polycarbonate

This material attracts with its translucency: under the canopy covered by it, it will never be excessively dark.

How to make a polycarbonate canopy on a wooden frame with your own hands?

- On top of the beams with a step of 0.8 - 1 meter, a transverse crate is launched from a bar with a section of 40x40 - 50x50 mm. The step of the crate is no more than half a meter.

- Polycarbonate is attracted to the crate with wood screws already familiar to us with rubber press washers. The main thing is not to overtighten them: the honeycomb structure of the roofing material makes it unstable to significant compressive forces.

One of the problems with translucent material is that the cavities in it collect a large amount of pollution over time. How to make a polycarbonate canopy yourself, which will keep a neat appearance for many years?

- Between themselves, the sheets are connected by H-shaped profiles, which sit on a silicone sealant.

- Similarly overlap edge profiles and ends on those sides where the honeycombs open.

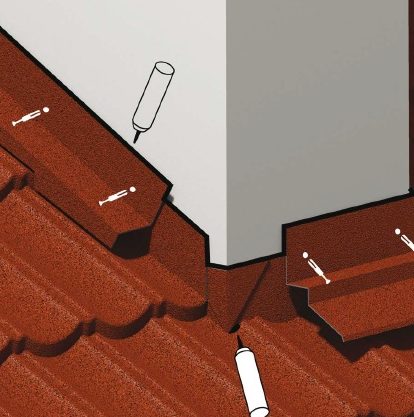

Attachment to walls

In order to prevent splashes flying off the canopy from causing fungus to appear on the walls over time, they can be protected in two ways.

- The wall is lined with a sheet of galvanized or polymer-coated steel, bent with an overlap on the canopy. The sheet is fastened with galvanized dowel screws; before its edges are attracted, they are smeared on the inside with sealant.

- An alternative solution is to use waterproofing "rubber" paint. She will not let water through to the main wall; the inevitable streaks on the surface of the paint itself, if desired, are easily washed off with any detergent.

Useful little things

- If you independently draw up a procurement plan and drawings - how to make a polycarbonate canopy with your own hands with a minimum amount of waste? The answer is simple: it is enough to make its main dimensions a multiple of the sheet size.

- Do not know how to make a canopy from the rain in nature, but do not want to spend money? The economy option is a dense plastic film draped over the lower branches of a tree or shrub. However, a much more sensible solution for outings into nature is to take a small tent: modern designs weigh a little more than a kilogram and assemble in 5-10 minutes.

Conclusion

We hope that our recommendations will help the reader in the construction of a yard canopy. As always, additional thematic information can be found in the attached video in this article. Good luck!

Did the article help you?