Of all the roofing materials for individual housing construction, asbestos-cement sheet steadily ranks first. In the construction of industrial buildings, it is also actively used, especially 6-corrugated wave slate, which has a large thickness, and, therefore, strength. What are the features of this popular material - later in the article.

The history of asbestos-cement roofing material (however, recently asbestos has been increasingly replaced by more “healthy” chrysotile) dates back to 1903, when it was first produced in Europe.

In Russia, the first production was opened in 1908, that is, its history goes back more than 100 years.

During this time, technology has changed more than once, but the main assortment remains unchanged: in private housing construction, 7 and 8 wave slates are still the leader.

These modifications have sufficient strength, at the same time they have a relatively small weight, and a good ratio of useful and nominal area:

| Leaf Profile | Dimensions | Leaf area, sq. m | Weight, kg | Usable area (overlap 16 cm), sq. m | Number of sheets to cover 100 sq.m. roofing |

| 8 wave | 1,75×1,13×0,0058 | 1,9775 | 26,1 | 1,5717 | 64 |

| 7 wave | 1,75×0,98×0,0058 | 1,7150 | 23,2 | 1,3356 | 75 |

In fact, these two profiles can be called twins, since they have exactly the same characteristics, differing only in width. The difference in size allows you to choose the material for your own needs: either with a large roof covering with one sheet, or, for areas with difficult terrain, with less waste.

In accordance with GOST 30340-95, 8 wave and 7 wave slates are produced with the following parameters: wave height h - 40 mm, wave pitch (distance between adjacent ridges) - 150 mm, and sheet thickness - 5.2 or 5.8 mm.

Important information!

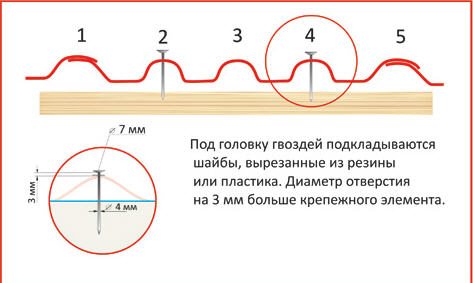

Slate roofing is mounted with overlapping sheets in horizontal rows. In this case, the overlap can be 1 or 2 waves.

With a double covering, as a rule, roofs with a slight slope (12-17%) are mounted, or those operated in harsh conditions - with strong winds, an abundance of precipitation, etc.

For various buildings and structures for industrial, agricultural and warehouse purposes, in most cases, slate 6 of the wave profile 54/200 is used (wave height 54 mm, wave pitch - 200 mm).

It has a thickness of 6 or 7.5 mm and a width of 1125 mm. 6 mm sheets have almost the same properties as the 40/150 profile

6 wave slate with a thickness of 7.5 mm - the material is more serious. It is significantly superior to other modifications:

- Has a higher density

- Withstands high bending load

- In terms of impact resistance, it surpasses other profiles by one and a half times

- In terms of defrosting cycles (service life), it has twice the durability (50 years versus 25 for other brands)

Of course, you have to pay for higher strength characteristics: if 6 mm metal profile for roofing 54/200 weighs about 26 kg, then 7.5 mm is already 35, which significantly increases the total weight of the roof structure.

Important information!

Covering and covering (extreme) waves of any sheet have different sizes. If this is not taken into account when laying, the waterproofing of the roof will be initially violated.

In order to avoid such incidents, as a rule, the sheets are laid out on the roof before laying, orienting them in advance in the right way. At the same time, this helps to speed up the installation process of the coating.

Slate 5 wave can be considered a comparative novelty on the market. It is produced by a single enterprise - Balakleysky Slate Plant LLC.

The size of the sheet is completely identical to the eight-wave slate - 1750x1130, with a thickness of 5.8 mm, but the profile itself has been changed. If for other modifications the waves along the entire diameter of the sheet have the same size, then the 5-wave geometry is somewhat different.

Between the actual waves of the sheet are flat areas. It is still difficult to judge how much such a geometry improves operational properties, since this profile has been produced for only a few years.

Therefore, it will be possible to evaluate its durability and practicality only after a certain time.

All types sheet slate currently available in classic gray or tinted version.

Moreover, to give the sheets color, two technologies are used: applying paint to the outside of the sheet (such a material is called colored) and adding pigment directly to the raw mixture (this option is called color).

Naturally, the second method is much more promising:

- Paint on such slate roof does not fade

- No efflorescence (whitish spots on the surface)

- When cutting the material, the edges have the same color as the entire sheet

- Does not leave unpainted marks in the event of scratches and other damage on the surface

Low cost, good service life, ease of installation, and the appearance regularly improved by manufacturers is a guarantee that wave slate will occupy a leading position in the building materials market for a long time to come.

Did the article help you?