One of the roofing options that you can equip in a fairly short time is an ondulin roof: you can equip such a roof with your own hands even without the involvement of third-party specialists.

And this means that you can not only save a lot, but also control the quality of work - and in the end you will get a beautiful, durable and reliable roof.

A few words about ondulin

Ondulin as a roofing material

Before describing the device of the roof from ondulin, it is necessary to understand - what is ondulin?

According to its structure, ondulin is a kind of slate made of flexible material. The basis of ondulin is an organic mass, which is impregnated with bitumen.

To ensure the ondulin (and hence the roof from it) water resistance and high strength, impregnation is carried out in a high pressure chamber, heating the bitumen to a temperature of 120 - 140 degrees.

The composition of ondulin includes:

- Cellulose fiber base

- Filler (mineral component)

- Resins to increase the heat resistance of ondulin

- Pigments of mineral nature (dyes)

The organic fiber base used provides a unique surface texture that distinguishes ondulin - a roof made of this material has a very presentable appearance and retains its original beauty for a long time.

Ondulin: benefits

Ondulin roofs are quite popular both in the EU countries (which is understandable, because it was in Europe that ondulin was introduced to the wide mass construction market), and in our country.

This popularity of ondulin is explained by its excellent characteristics:

- Roof roofs ondulin allows you to get a practically waterproof roof. The thing is that ondulin, made in compliance with the technology, is characterized by almost zero water absorption, and even when it is wet for a long time, it does not absorb moisture.

- Also, ondulin is highly resistant to temperature effects: it equally well tolerates both heat and cold.In addition, with sudden changes in temperature (for example, during the first frost), ondulin does not show a tendency to crack, unlike some other roofing materials.

- Despite the fact that ondulin is based on organic matter (most often it is cellulose), ondulin is biologically inert. Thanks to bituminous impregnation, ondulin is not damaged by bacteria, fungi, and is also of no interest to carpenter insects. The chemical resistance of ondulin is also sufficient - most of the acids and alkalis used in everyday life do not damage it.

- An important advantage that justifies the installation of an ondulin roof for industrial buildings is its oil resistance.

In addition to all of the above, ondulin is resistant to ultraviolet radiation (does not change color even after several years of operation), and also has a small mass. The last argument is very important if you are covering the roof with ondulin on your own. You will not only save energy on lifting the ondulin to the installation site, but you can also use thinner rafters with a lower bearing capacity.

As you can see, there are enough arguments in favor of using ondulin. Next, we will consider the very technology of arranging a roof from this material.

Installation of an onduline roof

Preparing for installation

In fact, roof installation using ondulin does not differ from the installation of a slate roof, however, there are still some nuances, and they must be taken into account.

So let's get started with the installation. To begin with, it is necessary to calculate the ondulin on the roof - i.e. determine how many sheets of ondulin you need to purchase.The easiest way to calculate the volume of ondulin required for purchase is to use a special calculator program.

As a rule, such programs can be found on the websites of ondulin manufacturers, but in addition to them, there are a sufficient number of similar applications. If you are repairing an ondulin roof, everything is much simpler: you need to buy exactly as many sheets as you need for replacement.

After the calculation is made and the ondulin is purchased, you can proceed with the installation work.

Note! Ondulin can be mounted only under certain conditions. Most manufacturers recommend installing ondulin at positive temperatures (from 0 to 30 degrees).

This is due to the fact that in the cold, ondulin becomes brittle for fracture: an already laid ondulin roof does not suffer from this, but when manipulating an ondulin sheet, and especially when breaking it with a nail, there is a risk of a crack.

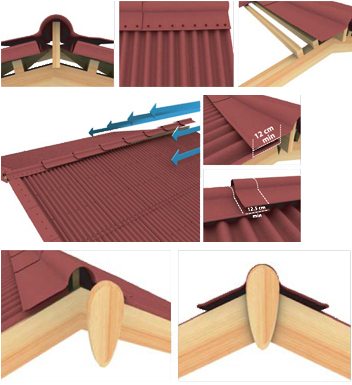

- Ondulin is fastened to the crate using nails with specially shaped caps. The consumption rate of fasteners for ondulin roofing for a standard ten-wave ondulin is 10 nails for the top of the sheet and 10 for the bottom.

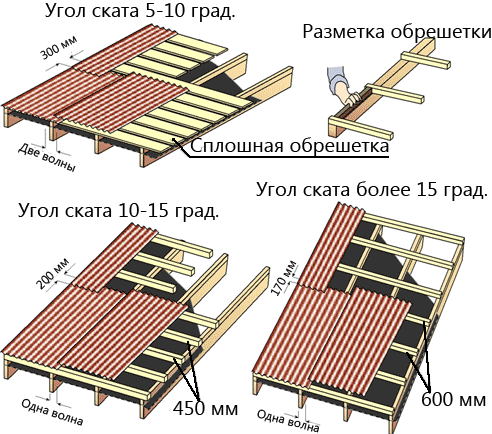

- For gentle roof slopes (up to 10 degrees), we mount a continuous crate of moisture-resistant plywood under the ondulin. On slopes with a greater steepness, it is allowed to equip a sparse crate from a bar, and the greater the angle of the slope, the less frequent the pitch of the crate.

- The technology for covering the roof with ondulin does not provide for the mandatory laying of waterproofing materials.However, it is better to “overdo it” and lay a layer of hydro and vapor barrier on top of the crate. Especially - if there is a heated attic or attic under the roof.

!!!!!!!!!!!!!!!!!!!!!

Laying and fixing ondulin

After the waterproofing is laid, the preparations can be considered complete. It's time to move on to laying ondulin sheets and fixing them.

Note!

Ondulin due to the structure of the cellulose base has the property of "stretch".

However, it is impossible to lay it tight in any case, otherwise, as a result of temperature deformations, the roof will definitely leak!

- During installation, we lay the sheets of ondulin apart - so that the joints of the horizontal row are opposite the whole parts of the sheets of the adjacent row.

- The overlap of the ondulin during laying depends on the slope: if the slope angle is less than 10 degrees, we make a vertical overlap of 30 cm or more, and a lateral overlap in 2 waves. For slopes of greater steepness, an overlap reduction of up to 20 cm and one wave, respectively, is allowed.

- We fix the ondulin in a “zigzag”: the lower part is fixed in each wave, after which, alternating waves, we drive nails alternately into the upper and middle parts.

Note!

If a crate made of a galvanized metal profile is used for the roof, we fasten the ondulin not with nails, but with metal screws with a drill and a cap of a special shape.

The installation is completed by fixing the cornice strips and skates.

It is according to this technology that the roof is covered - ondulin in this case is one of the most suitable materials for an inexperienced master.So, even if you have not encountered roofing work before, do not despair - but try to follow these instructions as accurately as possible.

Did the article help you?