Bituminous tiles are a roofing material with high elasticity, which provides reliable protection against moisture. In the article I will talk about the features of this material, consider its pros and cons, and give tips for self-laying.

Features of a soft roof

For proper installation of bituminous tiles, it is necessary to choose high-quality materials. One of these is bituminous mastic for roofing.The company NEFTEPROMKOMPLEKT represents only materials of excellent quality, the characteristics of which can be studied on the official website.

Product structure

Bituminous roofing is assembled from separate flexible elements that form a beautiful, durable and resistant to external influences roof. These elements are usually called flexible or shingles - primarily because of the external similarity.

Good performance characteristics of roofing material are determined by its structure:

- The basis of roofing sheets is a durable fabric made of fiberglass or polyester. In high-quality varieties, it is polyester that is used, due to which bituminous tiles acquire increased tensile strength. This quality is very important, since the reliability of fixing the material on the crate depends on it.

- The cloth is processed by impregnation from the modified bitumen. If earlier exclusively oxidized bitumen was used for this purpose, today it has been replaced by a material with the addition of SBS polymers. The advantages of modified bitumen include increased elasticity and resistance to extreme temperatures. The tile does not soften in the heat and does not become brittle even in severe frosts.

SBS polymers are styrene-butadiene-styrene compounds that are also used in the production of artificial rubber.

- A strip of self-adhesive bitumen is applied from the back layer - as a rule, also modified using SBS polymers.During installation, the roofing material is additionally heated with a building hair dryer, and the tiles are securely glued to the base - the lining carpet or the crate.

- To give the tiles additional strength and improve the appearance, a layer of mineral chips (basalt granules) is applied over the bituminous layer.

The result is a fairly light, durable and flexible multi-layer canvases that are easy to handle and assemble with your own hands.

Advantages

The bituminous tile made on modern technologies possesses a number of advantages.

These advantages make it a very popular roofing material:

- Good moisture resistance. The material itself is not afraid of moisture, in addition, the design of the tiles allows you to create a continuous coating with a minimum number of gaps. This minimizes the risk of leakage.

- Resistance to temperature influences. Thanks for this should, as you already understood, SBS polymers used to modify bitumen. The soft roof retains its elasticity both in the summer heat and in severe frosts, which helps to avoid cracking.

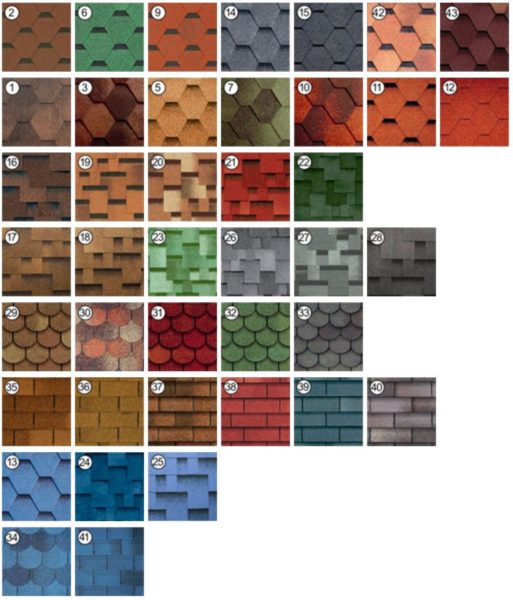

- Attractive appearance. The production technology allows to make roofing coverings of any shapes and shades. That's why choose the option that is ideal for design at home is not difficult.

- An additional plus is UV resistance. In the first two or three years after laying, bituminous tiles lighten slightly, but after that, fading practically stops. As a result, the roof remains attractive even 10-15 years after installation.

- Fire resistance. If the old models of material impregnated with oxidized bitumen burned well, then with the use of polymer impregnations, the situation has changed significantly. Modern flexible roofing does not ignite, does not burn and does not support combustion.

- Long service life. Manufacturers give a guarantee of 10 to 20 years, but in practice, the coating retains its properties for at least 30-40 years.

- Finally, the advantages include the moderate price of the material. Budget models cost from 200 rubles per square, a mid-level roof will cost you about 300 - 400 rubles / m2. For a material of this class, this is more than acceptable!

It should be noted that the price indicated here is only for the tiles. When calculating the budget, be sure to keep in mind that the total amount will include the cost of installing the crate, waterproofing, purchasing and installing additional elements, etc.

Another obvious advantage can be considered a fairly simple installation, which is quite feasible with our own hands. I will tell you in detail about the technology of laying shingles below, so that you can significantly save on the wages of roofers.

Flaws

When designing a roof made of bituminous tiles, it is necessary to take into account the disadvantages of this material:

- The required level of moisture resistance of a tiled roof is achieved with a slope of at least 120.If the slope angle is smaller, the risk of leaks increases significantly.

- With slopes up to 18-200, in addition to the crate, installation of a lining waterproofing carpet is required. It is desirable to mount the lining not only in problem areas, but also over the entire area of \u200b\u200bthe slope, which significantly increases the cost of the roof.

- Installation of flexible material can be carried out in a limited temperature range - from +5 to +25 ... 27 0С. In the cold, there is a risk of cracking the material during laying or fixing; in the heat, the material acquires increased elasticity and can be damaged when moving over it.

To avoid this, in the cold season, the tiles are heated with a building hair dryer. They also try not to walk directly on the slopes, using ladders or wooden platforms.

- Another disadvantage is the complexity of repairing and replacing damaged roof fragments. The thing is that the material sticks together due to the polymerization of bitumen, and it takes effort to cut out part of the tile.

However, despite the shortcomings mentioned, bituminous roofing is constantly growing in popularity. And if you want to master the technique of roofing, carefully study the following sections.

Materials and tools

For the construction of a roof using flexible shingles, you will need:

- The roofing material itself (reserve - at least 10% of the area of \u200b\u200bthe slopes).

- Additional elements - wind and cornice strips, cornice tiles, valleys, etc.

- Underlayment waterproofing carpet.

- Lining tapes for valleys, skates, etc.

- Lathing material - moisture resistant OSB-boards, plywood, boards.

- Fasteners for the crate and the tile itself.

- Bituminous adhesive (used for additional fixation if there is no self-adhesive layer).

- Antiseptic impregnation for wood.

Now - a set of tools:

- Wood saw (disc or hacksaw).

- Screwdriver.

- Hammer.

- Levels (long and short)

- Plumb.

- Roulette.

- Knife for cutting material.

- Construction stapler.

- Spatula for applying glue.

- Building hair dryer.

- Belt for tools.

- Safety system for work at height.

In addition, you need to take care of the availability of stairs for climbing to the roof and moving along its slopes.

Preparing for styling

crate

Flexible tiles are mounted on a solid crate, which is made either from OSB-plate, or from plywood, or from a planed board. For installation, use a material whose moisture content does not exceed 18 - 20%. All wooden parts are treated with a penetrating antiseptic.

The thickness of the lathing details depends on the step with which the roof rafters are installed. When choosing, you should focus on the table:

| Rafter pitch, m | Board thickness, mm | Plywood/OSB thickness, mm |

| 0,6 | 20 | 12 — 15 |

| 0,9 | 22 — 25 | up to 20 |

| 1,2 | 30 or more | 25 or more |

The installation of the crate is carried out as follows:

- All parts are adjusted in size so that the gap between them is about 5 mm.

- Fragments of the crate are stacked on rafters and fixed with nails or screws.

- Docking of boards or sheets of plywood is carried out only on the rafters. In this case, the edges of the parts are fixed at several points, after which they are additionally connected with galvanized steel brackets.

- When docking, a gap must be left, laid down when trimming parts. Due to this, the roof planes will not be deformed when the wood swells from moisture.

Lining

Although bituminous roofing has good moisture resistance, there is still a risk of leakage at some points on the roof.

In order to avoid such a development of the situation, a waterproofing lining carpet is mounted under the shingles:

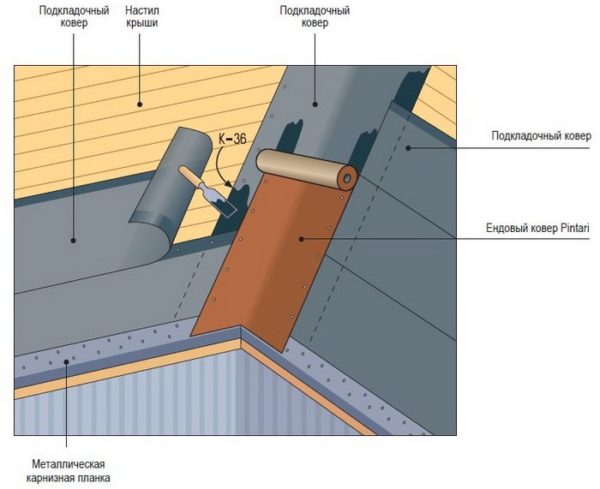

- The configuration of the waterproofing depends on the slope of the roof. If it exceeds 180, then waterproofing is placed in the valleys, along the ends and cornices. If the slope is less, then the lining must be placed over the entire area of \u200b\u200bthe slopes, otherwise leaks are inevitable.

- We start work with finishing the perimeter. To do this, we glue the lining cloth with a width of about 50 cm along the cornice light and along the ends of the roof.

- We roll out one roll on the skate, laying 25 cm on each side.

- In the inner valleys we fix special tapes - the so-called valley carpet. If there are no such tapes, then you can cut the moisture-proof membrane into strips and stick it on the bituminous mastic.

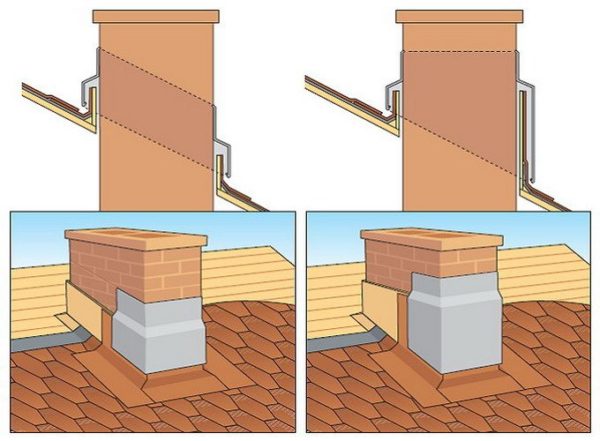

- We also paste over all the joints of the slope with vertical surfaces - walls, chimneys, exits to the roof, etc.

- If necessary, we lay the waterproofing on the entire plane of the slope. We place the rolls horizontally, overlapping the sheets by at least 10 cm.

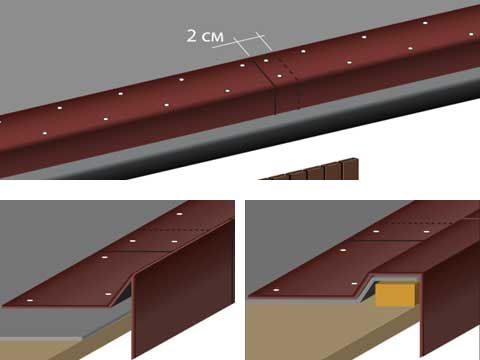

- At the same stage, we mount the end and cornice strips. For fixing metal profiled parts, we use galvanized nails, which we hammer in with a step of no more than 150 mm in a checkerboard pattern.

Tiling

The final stage is the installation of shingles on the prepared base.

Before starting the laying of the packaging with roofing material, it is advisable to open and leave for at least an hour - so the base impregnated with bitumen will acquire the ambient temperature and will not deform.

It is also worth mixing strips (shingles) of tiles from several packages - this will compensate for minor differences in color, which can even be within the same batch.

Installation instructions for flexible roofing assume the following sequence of work:

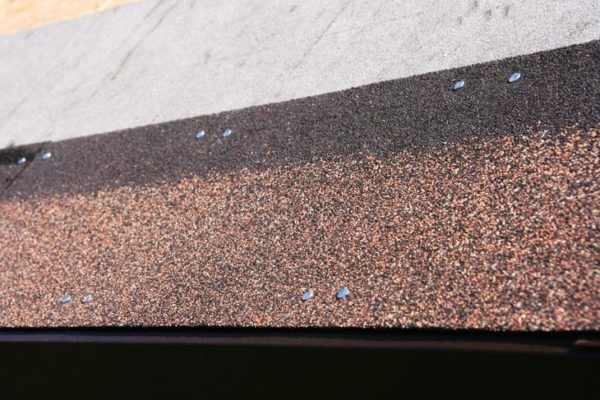

- The first step is the installation of the so-called cornice strips. The cornice strip is a bituminous tile of a rectangular shape (i.e. without figured cutouts), 100 - 150 mm wide. We lay the strips on the cornice strip and fix them with nails, hammering them every 20-30 mm at a distance of about 20 mm from the edge of the cornice. We glue the joints of the strips with bituminous mastic, the far edge is fixed on the crate due to the self-adhesive layer.

- Now let's move on to the first row. We start fixing from the midline of the slope, laying the shingles so that the protrusions overlap the joints of the cornice tapes, and the lower edge of the tile is 10-15 mm from the cornice.

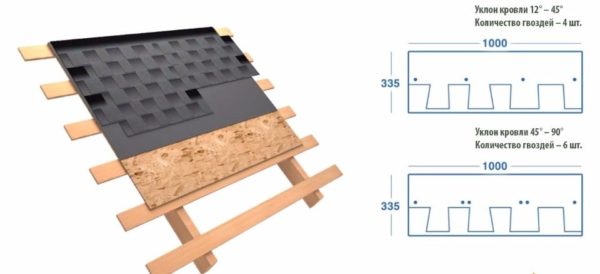

- The consumption of nails for shingles is 4-6 pieces per shingle. Nails are driven in immediately above the cutouts: in this way they additionally fix the previous rows, and their caps are closed with the protrusions of the next rows.

- We lay each next row with an offset - so that the joints do not coincide, and the protrusions are opposite the cutouts. Thanks to this placement, a continuous flooring is formed, which not only looks beautiful, but is also reliable due to double fixation.

- Where bituminous tiles reach the end of the roof or adjoin a vertical surface, we cut it with a knife with a minimum gap. The free edge must be glued to the crate in order to avoid tearing off by the wind.

- We lay a strip of roofing on the ridge, which we nail on both sides.

Installation of bituminous roofing is completed by installing additional elements - metal ridges (regular or ventilated), overlays for the junction of the roof to the walls, "aprons" of ventilation and chimneys, etc.

Conclusion

The bituminous tile possesses a number of advantages which do it by rather universal roofing material.The above are detailed recommendations for the correct installation of this coating. For more information about the installation technique, see the video in this article, and all questions should be asked in the comments.

Did the article help you?