To increase the life of the roof and increase its reliability during construction, a number of measures should be taken to ensure proper operating conditions, such as protection from precipitation, maintaining temperature, etc.

This article talks about what a waterproofing of a roof is and what materials are used for this.

Waterproofing - protection of building structures, buildings and structures from the penetration of water (anti-filtration waterproofing) or the material of structures from the harmful effects of washing or filtering water or other aggressive liquids (anti-corrosion waterproofing) (Footnote 1).

The main purpose of the materials with which the roof is waterproofed with one's own hands is to protect the insulation layer from moisture, which reduces its working properties.

Moisture can get into the insulation not only from the air, but also in the form of condensate formed from the inside of the roof covering and on the surface of the insulation due to the temperature difference.

Waterproofing materials can be divided into two groups:

- Membrane diffuse materials, which are the most modern material capable of releasing steam rising into the roof from the interior.

They should be installed on the inside of the insulation used. - Waterproofing vapor condensate filmsproviding additional protection house roofs against leaks, penetration of rainwater into ventilation inlets, etc.

They can be installed both as a waterproofing of a cold roof and a warm one and also provide protection of the insulation from moisture.

Useful: Membrane films are currently produced in the form of two- and three-layer materials that have both diffuse and anti-condensation properties.

In addition, they may include an adsorption layer in which the condensate accumulates and then evaporates efficiently.

Materials for hydro- and vapor barriers are most often produced in the form of rolls, which not only simplifies their installation, but also allows you to seal the joints of the edges and minimize seams. They must be used regardless of the type of roof and the material of its coating: waterproofing of an exploited roof or pitched, tiled or metal, etc.

Learn more about roof waterproofing

Roof waterproofing with liquid rubber - as one of the modern and popular options for protecting against moisture, allows the roof structure to work in the required mode, increases its service life, and also provides the necessary coziness and comfort in the house.

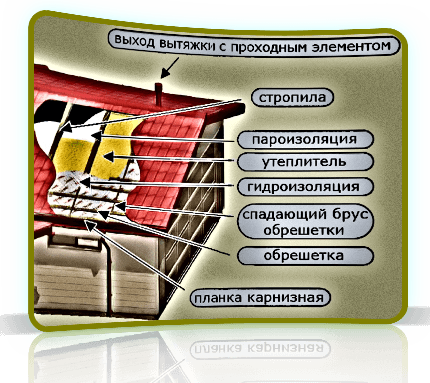

The right device roofing cake, which uses the necessary materials for hydro and vapor barrier, as well as the appropriate insulation, keeps the house warm, and also reduces the cost of heating the premises and prevents the penetration of moisture and condensate into the living quarters of the house.

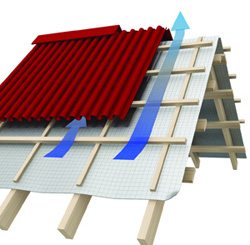

Roof systems provide for the installation of gaps for ventilation and the installation of a waterproofing film, with the help of which both external and internal moisture is removed from the under-roof space, allowing the roof to last as long as possible.

Ventilation protects the roofing material from heating from the side of the building itself and allows for uniform melting of the snow cover under the influence of heat or sunlight, preventing the formation of ice that leads to damage to gutters and overhead gutters.

As mentioned above, the materials used for waterproofing in general and under-roof waterproofing, in particular, are divided into two types:

- Diffusion membranes;

- Waterproofing and anti-condensation films for installation under the roof.

Diffusion membranes are quite expensive, but they also have a number of advantages:

- Possibility of laying directly on the insulation layer, which allows to reduce the thickness of the roof pie and use a larger amount of insulation;

- The windproofness of the membranes significantly reduces the amount of heat blown from the surface of the insulation layer;

- Increased vapor permeability from the inside and water tightness from the outside, providing the ability to "breathe" the roof.

In the process, when waterproofing a flat roof or any other, the vapor barrier film can be attached not only horizontally, but also vertically:

- Horizontal film fixing made on rafters located at a distance of no more than 1.2 m from each other. In this case, the film should not sag to a height of more than 2 centimeters, and should not come into contact with the insulation layer.

After the film is fixed, counter-battens are nailed to the rafters and the crate is erected. - Vertical film fastened with staples of a mechanical stapler or galvanized nails with flat heads on the inside of the thermal insulation layer to wooden load-bearing elements.

In this case, an overlap of at least 10 centimeters must be observed both horizontally and vertically. The connection of the individual strips of the film roll must be airtight, it is carried out using a connecting tape.

After the installation of the film is completed, special rails should be attached to provide a small free space between the vapor barrier and the ceiling.

Waterproofing and vapor barrier materials

There are the following materials used for roof waterproofing:

- Polyethylene filmsused for both steam and waterproofing;

- Polypropylene films, which are used mainly for roof waterproofing;

- Breathable non-woven membranes, used for the most part as waterproofing materials.

Films made of polyethylene and polypropylene are used in case of an increase in the section of the rafters to ensure the required rigidity, as a result of which a space is formed between the upper part of the rafters and the insulation layer.

Anti-condensation films are a type of such films, characterized in that water drops do not flow down, but linger in the lower layer, where they gradually dry out.

To use such a film, two ventilation gaps are required, the size of which (from 8 to 10 cm) is slightly larger than the size of the gaps for ordinary film, which is 5 centimeters.

Below is a table (Footnote 2) Description of waterproofing film based on Grand Line Silver D98 high-strength polypropylene fabric

| Material | Density | Water vapor diffusion* | Tensile strength (longitudinal/transverse)** | Roll size | Roll area |

| Woven fabric | 98g/m2 | Sd < 30m | 850N/5cm 685N/5cm | 1.5m x 50m | 75 m2 |

There are also two types of "breathing" membranes:

- "Super diffuse", which do not allow moisture to pass from the outside, but at the same time allow it to freely evaporate from the insulation. The vapor barrier of such membranes can be up to 1200 g/m2 per day.

The installation of such membranes is carried out directly on the insulation, which results in a continuous ventilation circuit between the coating and the film, reducing the thickness of the roof pie.

Superdiffusion film is also a protection of mineral wool insulation from the wind, "blowing" heat out of them. - "Diffusion breathable films" are polypropylene or polyethylene reinforced films with perforation, the holes of which must pass only steam, without passing moisture from the outside.

The vapor transmission capacity of such films is significantly lower than the membranes, so their laying directly on the insulation layer can cause a "greenhouse effect".

For the installation of such films, two gaps should be provided: both between the waterproofing and the insulation, and between the roofing and the waterproofing.

The materials with which liquid waterproofing of the roof is equipped must have the following qualities:

- fire resistance;

- Sufficient tensile strength;

- Resistant to sunlight;

- Acceptable noise insulation of the roof, etc.

Installation of waterproofing is recognized as performed correctly if it is carried out under all elements of the coating roofs, including overhangs of cornices and gables, the lower sheet of waterproofing is brought out into the drain or onto the frontal board outside the cornice, and also - the film fits snugly enough to the pipes and walls that may be on the roof.

Steam and waterproofing of the roof, made in accordance with SNiP, increase the protection of the roofing material and the thermal insulation layer, and also can significantly increase their service life.

Did the article help you?